B21, China Town Mall, Midrand

TH-PM-P-5 Automatic Powder Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600633649316

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What powder materials can the TH-PM-P-5 pack?

The TH-PM-P-5 is suitable for a wide range of powder products including milk powder, bean milk powder, spice powder, grain powder, seasoning powder, coffee powder, and flavoring powder. For unusual or highly abrasive powders, consult the supplier.

2. What is the filling capacity range of the machine?

The machine can accurately fill from 50 g up to 5,000 g per pouch or bottle.

3. How fast does the TH-PM-P-5 operate?

Typical filling speed is between 10 to 20 bags (or pouches) per minute, depending on product characteristics and bag size.

4. How accurate are the fill weights?

The machine maintains a filling weight accuracy of at least 99.5% under proper setup and calibration.

5. What are the machine's power requirements?

The TH-PM-P-5 operates on a 1000 W power supply. For voltage and plug type details (e.g., 110/220V, single/three-phase), check specifications with the supplier or your regional sales representative.

6. What bag and film types does it support?

The machine automatically packs into plastic pouches and is compatible with PE and laminated films. It is designed primarily for small bags and bottles.

7. What are the machine dimensions and weight?

Overall dimensions are 0.6 m (width) x 0.5 m (depth) x 2 m (height). The unit weighs approximately 100 kg.

8. Can the TH-PM-P-5 be integrated into an existing production line?

Yes. Its compact footprint and lightweight design make it suitable for integration. You may need conveyors, infeed/outfeed alignment, and possibly control interfacing — consult your supplier or technician for integration assistance.

9. How do I clean and maintain the machine?

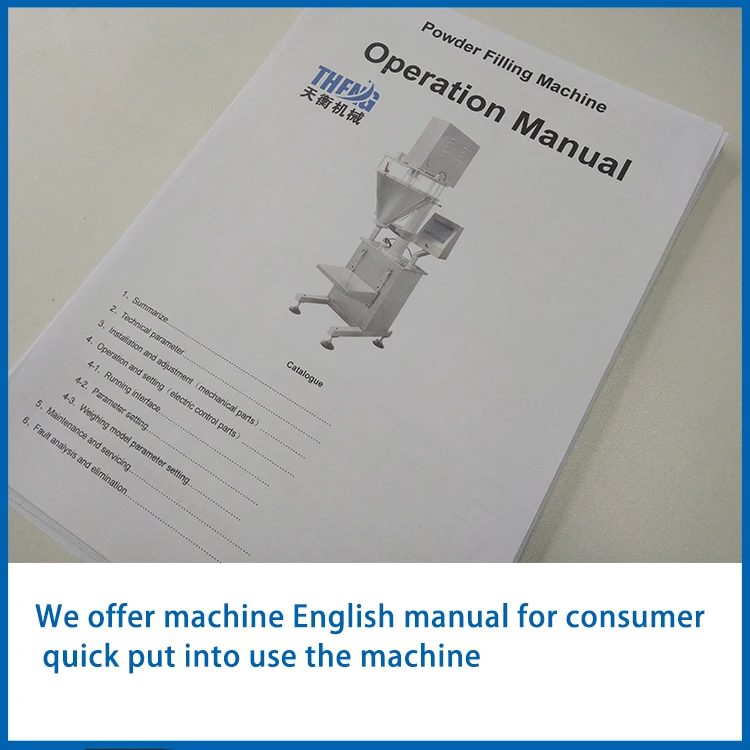

Perform routine cleaning of product-contact parts, keep sealing jaws and auger (if equipped) free of buildup, check and tighten fasteners, lubricate moving parts per the maintenance schedule, and replace worn components. Always follow the manufacturer's cleaning and safety procedures in the user manual.

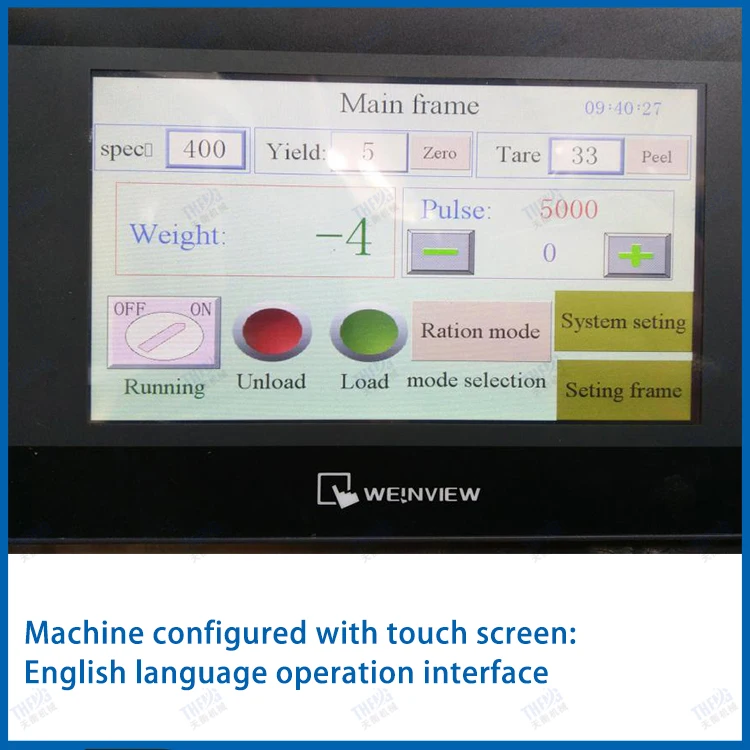

10. How do I calibrate filling weight for different powders?

Calibrate by running test fills, weighing samples, and adjusting dosing parameters in the machine controls until the desired target and accuracy are achieved. Repeat tests for consistency and consult the manual for specific calibration steps.

11. Are there powders that the TH-PM-P-5 should not be used for?

Very sticky, highly hygroscopic, or coarse/granular products that do not flow well may cause feeding or dosing problems. For high-moisture or extremely fine dust-producing powders, check with the supplier for recommended modifications or alternative machines.

12. What common spare parts should I keep on hand?

Useful spare parts to stock include sealing elements/jaws, cutting blades, auger or dosing components (if applicable), film rollers, belts, and common sensors. Availability and part numbers should be confirmed with the manufacturer or dealer.

13. Is technical service or installation support available?

Most suppliers provide installation support, commissioning, and after-sales service. Contact your vendor to arrange on-site setup, operator training, and service agreements.

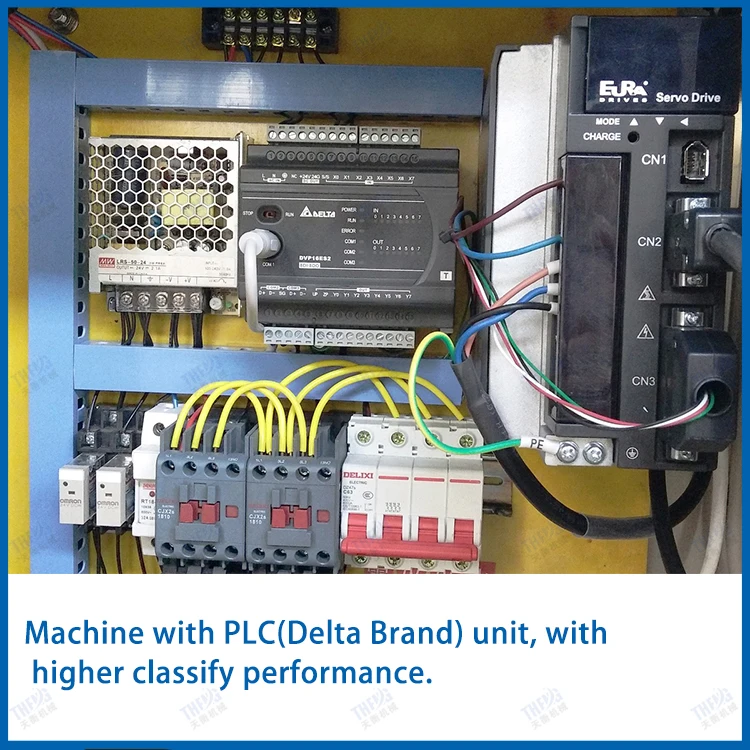

14. What safety features does the machine have?

Standard safety considerations include emergency stop(s), protective guards around moving parts, and electrical safety grounding. Refer to the machine's user manual for a complete list of safety features and safe operating procedures.

15. What warranty and certifications does the TH-PM-P-5 have?

Warranty terms and any applicable certifications (CE, ISO, etc.) are not listed in this description. Please request warranty information and certification documentation from the supplier before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading