B21, China Town Mall, Midrand

The ATM-320C/380C Granule Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600918630761

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

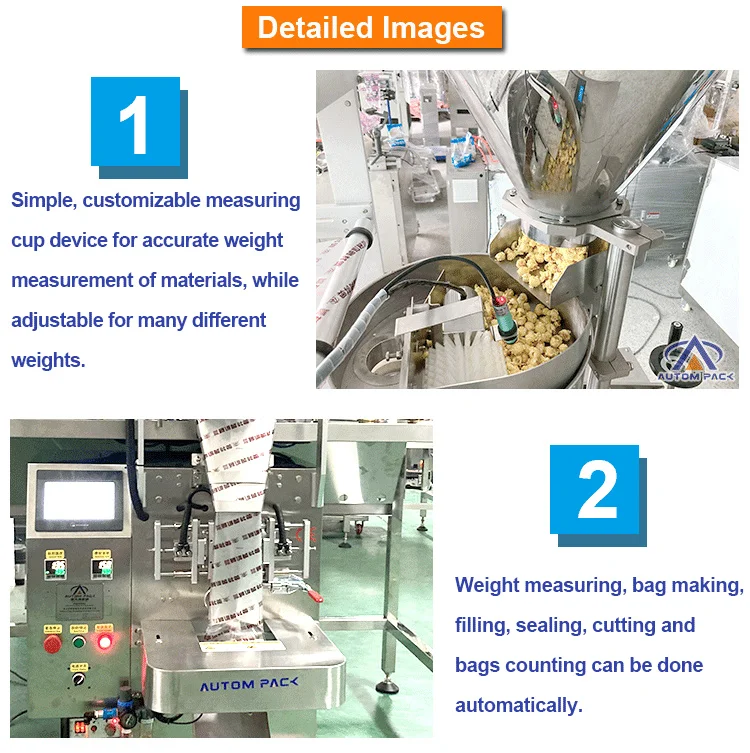

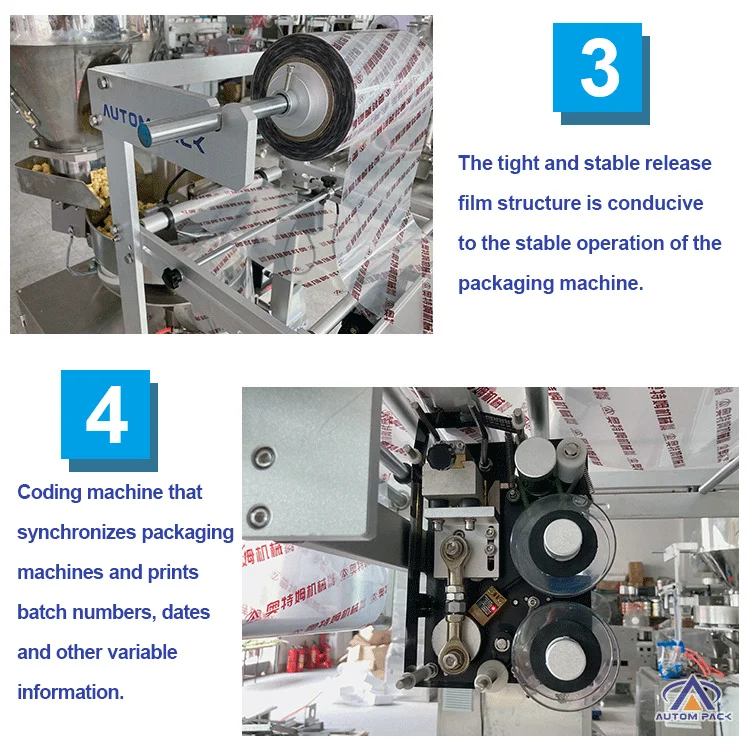

1. What is the ATM-320C/380C Granule Packing Machine?

The ATM-320C/380C is a fully automatic granule packing machine designed to measure, form bags, fill, seal, cut and count bags in a single automated process. It is built for high efficiency and precision in packaging loose granular products.

2. Which industries and products is this machine suitable for?

It is suitable for food, beverage, chemical, apparel and other industries. Typical products include puffed granules, popcorn, rice, sugar, nuts, candies, peanuts, shrimp bars and similar loose granular materials.

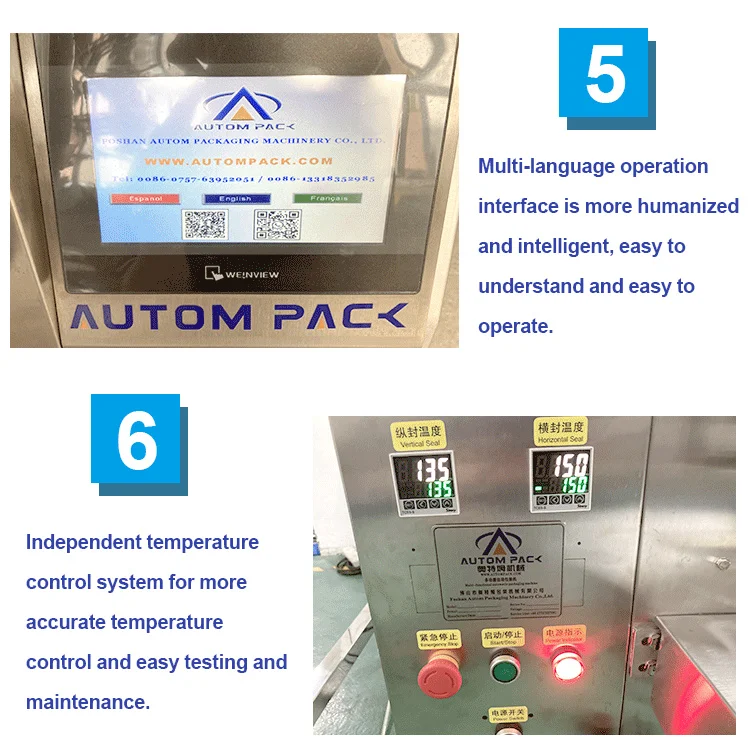

3. What bag types and film materials does the machine support?

Supported bag types include pillow bags, gusseted bags, chain bags and 3/4 side-seal bags. Compatible films include OPP/PE, CPP/PET, PE, KOP, VMCPP and VMPET, with film thickness from 0.04–0.12 mm.

4. What are the main differences between the ATM-320C and ATM-380C models?

Key differences: film width (ATM-320C: 120–320 mm; ATM-380C: 180–380 mm), bag length (320C: 50–200 mm; 380C: 60–280 mm), bag width (320C: 30–150 mm; 380C: 60–180 mm), film roll max diameter (320C: 300 mm; 380C: 320 mm), measuring range (320C: 1–1000 ml; 380C: 1–1500 ml), power consumption (approx. 2.2 kW for 320C, 2.5 kW for 380C), overall dimensions and gross weight (320C ~ L1200×W700×H1900 mm, ~320 kg; 380C ~ L1100×W800×H2150 mm, ~400 kg).

5. What is the machine's packing speed and production capacity?

Packaging speed ranges from about 5 to 80 bags per minute, depending on product, bag size and settings. Typical production capacity options listed include 30, 40, 50 and 60 bags/min; maximum quoted speed is up to 80 bags/min under optimal conditions.

6. How accurate is the weighing and filling system?

The machine uses automated weighing and filling controlled by PLC and a high-sensitivity photoelectric eye for precise color tracing and positioning. Accuracy depends on product characteristics and calibration, but the system is designed for consistent, repeatable fills.

7. Can the machine handle different granule sizes and densities?

Yes. The machines are designed for loose granular materials and offer adjustable measuring ranges (320C up to 1000 ml, 380C up to 1500 ml). Hopper, dosing and timing adjustments allow handling of various sizes and densities; very large, irregular or sticky items may require testing or customization.

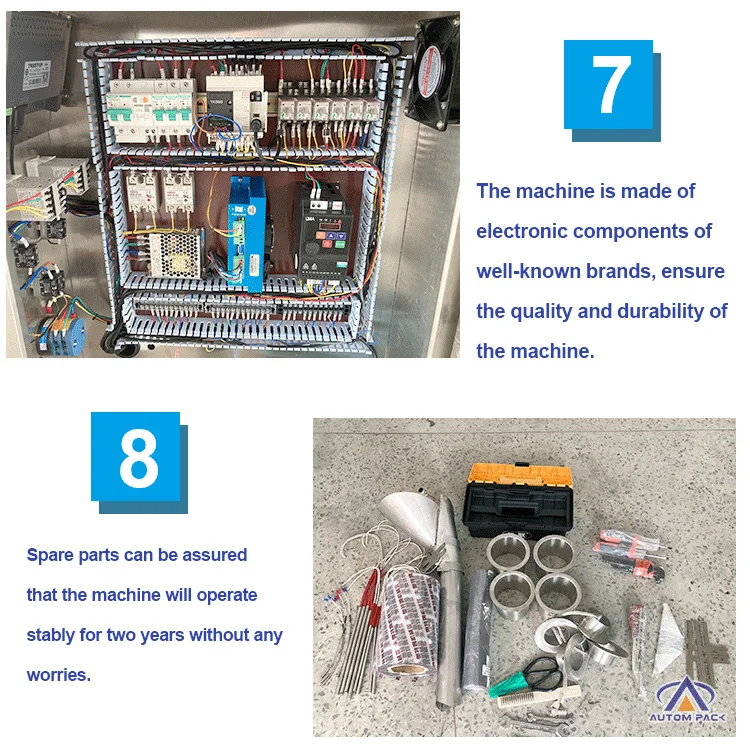

8. Is the machine easy to operate?

Yes. It features computer PLC control with an English–Chinese operation interface for user-friendly setup and control. Operators can set parameters for bag size, fill volume, speed and other functions through the HMI.

9. What are the electrical and installation requirements?

Power consumption is approximately 2.2 kW for the ATM-320C and 2.5 kW for the ATM-380C. Exact electrical supply (voltage/frequency) and site requirements vary by customer; professional installation and correct grounding are recommended. Contact the supplier for detailed installation specifications.

10. What warranty and after-sales support are provided?

The machine comes with a 1-year warranty. Core components are from reputable brands to enhance durability. After-sales support, spare parts and technical assistance are available through the manufacturer or authorized dealers—contact your supplier for details.

11. How should the machine be cleaned and maintained?

Regular maintenance includes daily cleaning of product contact areas, routine inspection and lubrication of moving parts, checking seals and cutting blades, and monitoring belts and sensors. Follow the manufacturer's maintenance schedule in the user manual to maximize performance and service life.

12. Can the ATM-320C/380C pack powders, pastes or liquids?

This machine is optimized for loose granules. Very fine powders, pastes or liquids typically require specialized dosing systems or different machine configurations. Consult the supplier to discuss product trials or necessary modifications for non-granular products.

13. Are spare parts and consumables available?

Yes. Common consumables include sealing jaws, cutter blades, belts and film rolls. Wear parts and branded core components are generally available from the manufacturer or authorized distributors—order lead times vary by region.

14. Can the machine be customized or integrated into an existing production line?

Yes. The ATM series is adaptable and can be configured for different bag styles, speeds and auxiliary equipment. Integration with upstream or downstream equipment (e.g., fillers, conveyors) is possible—contact the manufacturer to discuss customization, layout and control integration options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading

Machine

Machine