B21, China Town Mall, Midrand

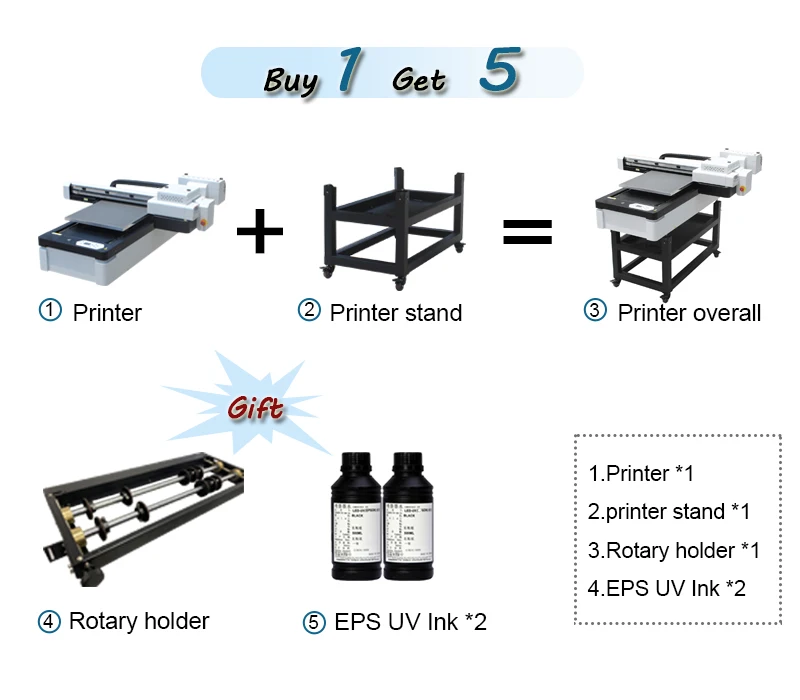

TH-6090 2-3 Head Inkjet Printer UV Flatbed Printer Machine for Phone Case

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 60830491317

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the TH-6090 UV flatbed printer?

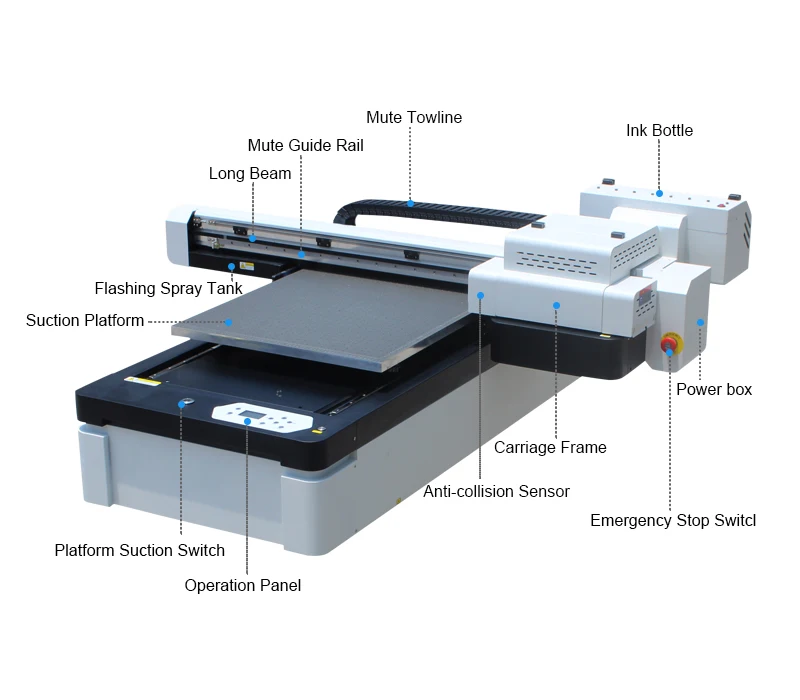

The TH-6090 is a small-to-medium UV flatbed printer designed for direct printing on rigid and some flexible substrates. It's commonly used for phone cases, signage, promotional items and other customized products.

2. Which print heads does the TH-6090 support?

The machine supports 2–3 print head configurations using Epson DX7, XP600, GH2220 or L1440 heads, allowing you to choose based on desired speed, resolution and budget.

3. What is the maximum printable area and material thickness?

Maximum print format is 900 mm × 600 mm (90 × 60 cm). The sinkable platform and platform lifting function allow printing on materials up to 15 cm thick.

4. What ink system and colors are available?

The TH-6090 uses UV-curable inks in CMYK plus White (CMYK+W). It also includes a secondary cartridge option to support longer print runs and minimize downtime.

5. Can the TH-6090 print on cylindrical objects and phone cases?

Yes. The printer offers an independent detachable cylindrical print holder for printing on bottles, mugs and other cylindrical items, and is suitable for phone case printing with proper fixtures.

6. What printing speeds and resolutions does it offer?

Typical speeds are approximately 4 m²/h (4-pass), 3.5 m²/h (6-pass) and 2 m²/h (8-pass). Supported resolutions include settings up to 360 dpi, 720 dpi and 1440 dpi depending on head and RIP settings.

7. What type of UV lamps and cooling does the machine use?

The TH-6090 uses LED UV lamps with air cooling for curing the UV ink, which improves energy efficiency and reduces heat exposure to substrates.

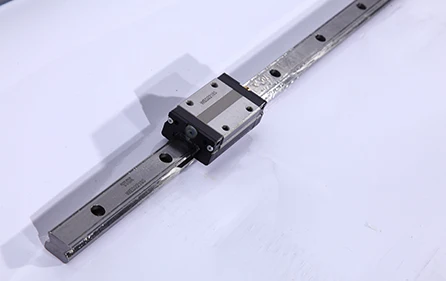

8. What notable mechanical and motion components are used?

Key components include a FUJI servo motor control system for precise motion control, THK linear rails imported from Japan for low friction and durability, and a silent DuPont PA66 nylon towline designed for toughness and low friction.

9. Which file formats and software are supported?

The printer is used with RIP software for print control. It typically supports common file formats such as TIFF, JPEG, PNG and PDF as input to the RIP; vector files should be exported as high-resolution raster or handled through compatible RIP workflows. Confirm the exact RIP package with your supplier.

10. What maintenance is required?

Routine maintenance includes daily head capping and cleaning cycles, periodic nozzle checks, keeping ink cartridges topped up, cleaning the flatbed and fixtures, and replacing consumables (waste ink pads, UV lamps, filters) per usage. Follow the manufacturer maintenance schedule to preserve print quality and head life.

11. Are replacement parts and consumables available?

Common consumables and spare parts include print heads, UV lamps, ink cartridges, drive belts, and service kits. Availability varies by supplier—ask your vendor about recommended spare parts to keep on hand.

12. What are the installation and training options?

Most suppliers provide on-site or remote installation and operator training as part of the purchase or as an add-on service. Confirm with the seller what installation, test prints and training are included.

13. What power, space and environmental conditions are required?

Exact power and space requirements are not listed in the brief. In general, the machine needs a stable power supply, a flat dust-minimized workspace with good ventilation for general working conditions, and sufficient clearance around the printer for loading media and maintenance. Request the detailed technical manual from the supplier for precise specifications.

14. What warranty and technical support are provided?

Warranty terms and support packages vary by seller and region. Contact your vendor to confirm warranty length, coverage (heads are often excluded or limited), availability of local service agents and options for extended support.

15. Does the TH-6090 have certifications or compliance information?

Certification and compliance (CE, FCC, RoHS, etc.) depend on the specific model build and supplier. Request certification documents and safety data sheets from your vendor prior to purchase if compliance is required for your market.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading