B21, China Town Mall, Midrand

Tank Stainless Steel Restaurant Container

- Section : Machinery

- Category : Food & Beverage Machinery

- SKU : 1600911774338

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Tank Stainless Steel Restaurant Container used for?

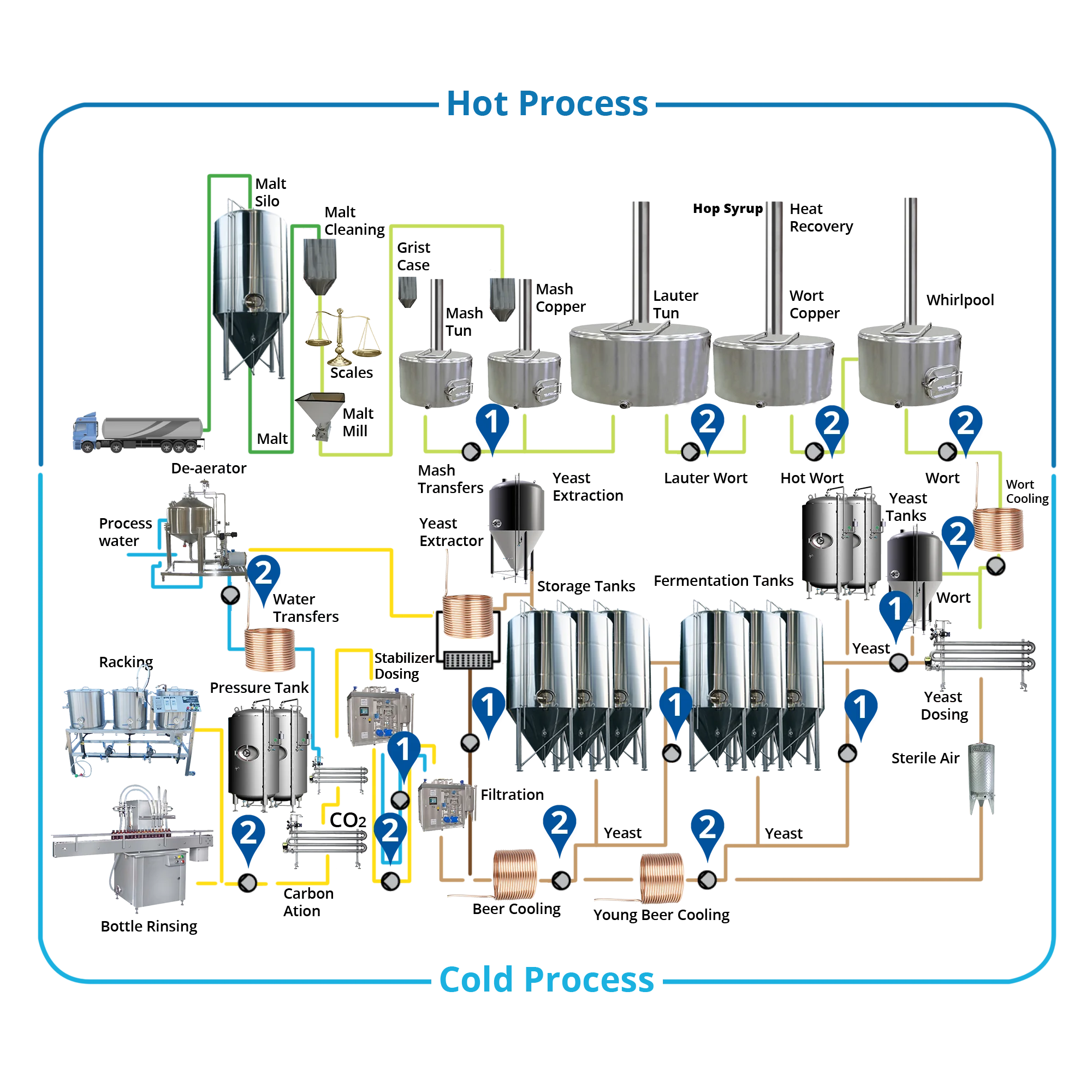

This is a stainless steel fermentation tank designed for fermenting beverages such as beer, wine, cider, kombucha and cold-brew coffee. It provides a controlled, sanitary environment for microorganisms to carry out fermentation and is suitable for home brewers, commercial breweries and restaurants.

2. What materials and construction standards are used?

Tanks are fabricated from SUS304 stainless steel. According to the specification the inner jacket and seal head are 3.0 mm thick and the external jacket is 2.0 mm, giving good pressure resistance and abrasion durability. The product spec also references abrasion-resistant copper material for certain components. Surface polishing is finished to Ra0.4 μm for sanitary performance.

3. What sizes and capacities are available?

Models range from ZYL-500 up to ZYL-5000. Capacities listed run from about 500 L/day (≈132 US gallons) up to 5000 L/day (≈1320 US gallons). Each model includes specific tank diameters, heights and heating jacket areas — e.g., ZYL-500: Ø1160 mm × 2800 mm with 0.5 m² heating area; ZYL-5000: Ø2260 mm × 4400 mm with 5.0 m² heating area. Contact sales for the full spec sheet and dimensional drawings.

4. How do I choose the right tank size for my operation?

Choose based on desired daily/weekly throughput, fermentation cycle length, batch size and available floor/ceiling space. For example, if you need X liters per day and your fermentation cycle is Y days, select a tank (or number of tanks) whose total working volume covers that steady-state production. We can assist with calculations and recommendations if you provide your target output and process details.

5. Does the tank include a cleaning system?

Yes — the tanks are equipped with a CIP (Clean-In-Place) cleaning system to allow automated internal cleaning and sanitation without disassembly.

6. How is temperature controlled — does the tank have a jacket?

Tanks include jackets for heating/cooling. The specification lists a heating area for each model (e.g., 0.5 m² to 5.0 m²). Jackets are used with glycol, water, or steam systems depending on your process and should be plumbed to an appropriate temperature-control system supplied or specified separately.

7. What level of surface finish and hygiene can I expect?

The interior is polished to Ra0.4 μm, a sanitary finish that minimizes microbial adhesion and eases cleaning and CIP performance.

8. Have the tanks been pressure tested?

Yes. The tanks undergo strict tank pressure testing during manufacture. If you require specific pressure ratings or test certificates, please request those details when ordering.

9. Can the tanks be customized for non-standard applications?

Yes. The manufacturer has experience producing fermenters for beer, wine, cider and kombucha and offers custom designs for other fermented products. Provide your process requirements (volume, pressure, temperature range, fittings, control needs) and engineers will create a tailored design.

10. What accessories and fittings are available or commonly supplied?

Common options include manways, tri-clamp fittings, racking arms, sample ports, sight glasses, pressure relief and sanitary valves, thermowells/temperature probes, insulation, insulation cladding, casters or skids, and instrumentation/control panels. Specific accessories are selected per order.

11. How should I clean and maintain the tank?

Use the built-in CIP system with recommended food-grade cleaning and sanitizing chemicals. Avoid abrasive tools that could damage the Ra0.4 μm finish. Regularly inspect gaskets, seals and welded joints, check valves and fittings for leaks, and follow your standard maintenance schedule for temperature-control and pressure systems.

12. What documentation, certifications or test reports are provided?

The standard supply includes manufacturing specifications and pressure-test records. If you need material certificates, third-party inspection reports or specific regulatory certifications, request these when ordering and we will provide available documentation or arrange inspections as required.

13. Do you provide installation, commissioning and after-sales support?

Yes — installation and commissioning support can be arranged. After-sales support, spare parts and technical assistance are available; contact sales for service options, associated costs and warranty terms.

14. What is the typical lead time and how do I get a quote?

Lead time depends on model, customization and order volume. To get a quote, provide the desired capacity/model, beverage type, required fittings/accessories, site constraints (dimensions, access, utilities) and any compliance needs. Sales will then provide pricing, estimated lead time and shipping details.

15. Is this tank suitable for use in restaurants and small-scale craft operations?

Yes. The tanks are designed to serve a range of customers from restaurants and home brewers to commercial craft breweries. Choose the model and accessory package that matches your production scale and space constraints.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading