B21, China Town Mall, Midrand

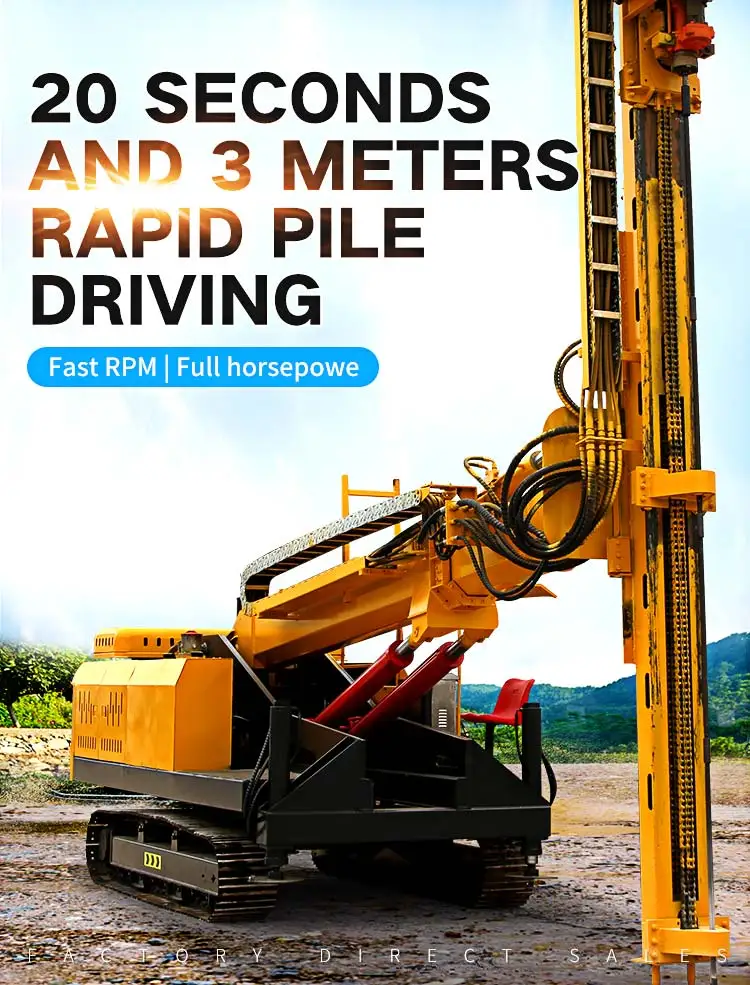

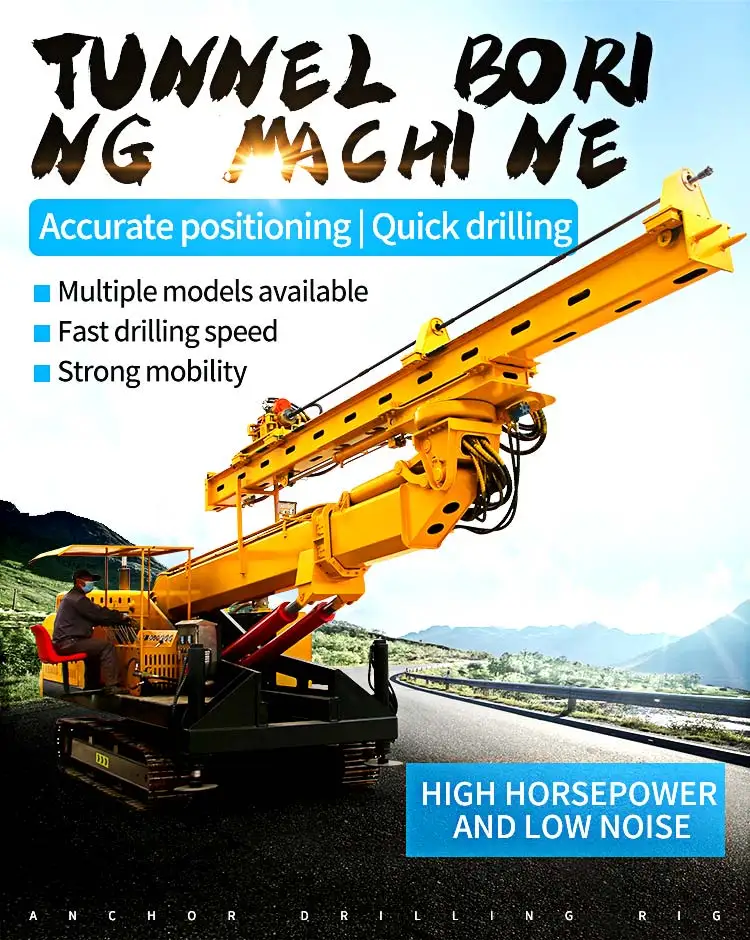

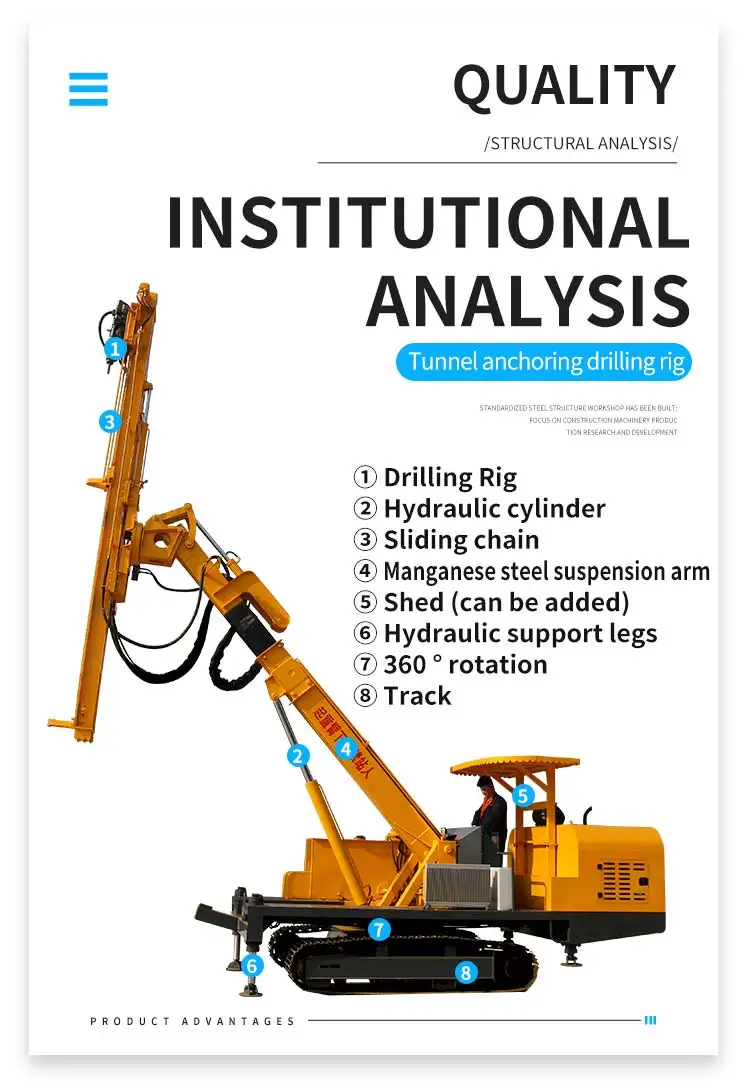

Surface Rock Blasting Portable Mining Equipmen

- Section : Machinery

- Category : Construction Machinery

- SKU : 1601208506163

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Surface Rock Blasting Portable Mining Equipment?

The primary function is to drill holes in all directions efficiently, making it ideal for various mining and tunneling operations.

2. How does this equipment improve drilling accuracy?

The design and technology of the equipment enhance precision in drilling, minimizing human error and ensuring consistent results.

3. Is the Surface Rock Blasting equipment easy to transport?

Yes, it is designed to be compact and lightweight, allowing for flexible movement and easy transportation to different job sites.

4. What types of materials can this equipment drill through?

It is capable of drilling through a variety of materials, including rock, soil, and other mineral deposits commonly found in mining operations.

5. Can the equipment be operated by a single person?

Yes, the flexibility and design of the equipment allow for efficient operation by a single user, reducing the need for a large team.

6. What are the dimensions of the equipment?

The exact dimensions can vary by model, but it is designed to be small in size for easy maneuverability in tight spaces.

7. How does this equipment reduce manual labor intensity?

By automating the drilling process and improving efficiency, the equipment decreases the physical effort required by operators.

8. Is the equipment suitable for all types of mining operations?

Yes, it can be used in various mining operations including surface mining, underground mining, and construction projects.

9. What safety features are included in the design?

The equipment typically includes safety guards, emergency stop buttons, and ergonomic designs to minimize operator risk.

10. Does it require specialized training to operate?

While basic operation can be learned quickly, we recommend training sessions for optimal use and safety compliance.

11. What is the power source for the Surface Rock Blasting equipment?

The equipment is usually powered by an electric motor or a diesel engine, depending on the model and application.

12. Can the drilling depth be adjusted?

Yes, the drilling depth can typically be adjusted based on the specific requirements of the job.

13. What maintenance is required for this equipment?

Regular maintenance includes checking moving parts, lubrication, and ensuring the drilling components are in optimal condition.

14. Is this equipment environmentally friendly?

The design aims to minimize environmental impact, but practices during operation should also align with environmental regulations.

15. What is the warranty period for the Surface Rock Blasting equipment?

Warranty periods can vary by manufacturer, but it typically ranges from one to three years depending on the specific model.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading