B21, China Town Mall, Midrand

Smt Production Line Mini Pick And Place Machine Automatic LED Making Machine Smd Pick And Place Machine For Pcb Assembly

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600538505963

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model number of the Mini Pick And Place Machine?

The model number of the Mini Pick And Place Machine is PPM-A320VB.

2. What is the maximum mounting speed of this machine?

The maximum mounting speed of the PPM-A320VB is 5500 pcs/hour.

3. What types of components can this machine handle?

This machine can handle a variety of components including RC elements (0402, 0603, 0805, 1206, etc.), LED lamp beads (0603, 0805, 3014, 5050, etc.), and chips (SOT, SOP, QFN, BGA, etc.).

4. What is the mounting precision of the PPM-A320VB?

The mounting precision is 0.025mm.

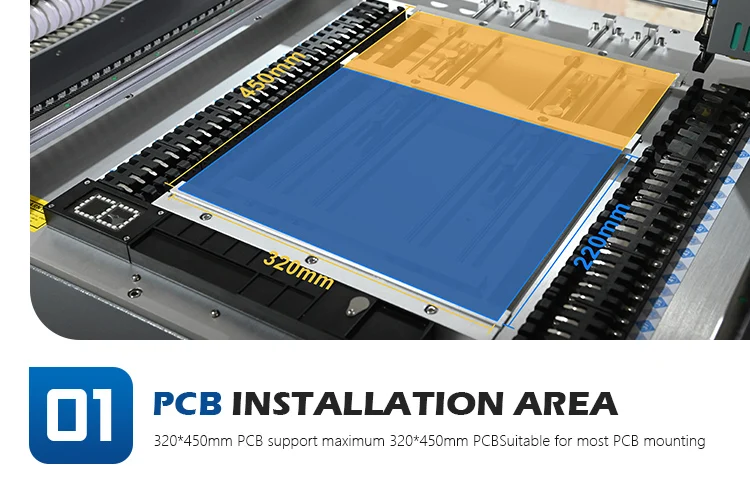

5. What is the size range for PCBs that can be used with this machine?

The PCB minimal size is 10×10mm and the maximum size is 320×450mm.

6. What types of feeders are compatible with this machine?

The machine supports components wheel types of 8mm, 12mm, 16mm, and 24mm.

7. Is the PPM-A320VB suitable for small batch production?

Yes, the PPM-A320VB is designed for proofing and small batch production.

8. What types of visual cameras are included in the machine?

The machine is equipped with 3 visual parts cameras and 1 PCB camera, featuring high-definition CCD technology.

9. What is the air pressure requirement for operation?

The air pressure requirement for operation is 0.4Mpa.

10. What software does the PPM-A320VB use?

The operational software is R&D, and it supports CSV and TXT file formats.

11. What is the weight of the Mini Pick And Place Machine?

The weight of the PPM-A320VB is 85 kg.

12. What power supply is needed for this machine?

The power supply required is AC220V±10% at 50Hz.

13. Can the machine be operated online and offline?

Yes, the PPM-A320VB supports both online and offline programming methods.

14. What is the suction nozzle type used in this machine?

The machine uses Juki series nozzles as its suction nozzle type.

15. Is there any customization available for the SMD height?

The standard SMD height capacity is ≤5.5mm, but it can be customized to ≤11mm.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading