B21, China Town Mall, Midrand

SF-150 Horizontal Heat Poly Bag Pouch Heat Sealer Automatic Continuous Sealing Shrink Sleeve Seaming Machine Max Steel Key

- Section : Machinery

- Category : Packaging Machines

- SKU : 1600254613837

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

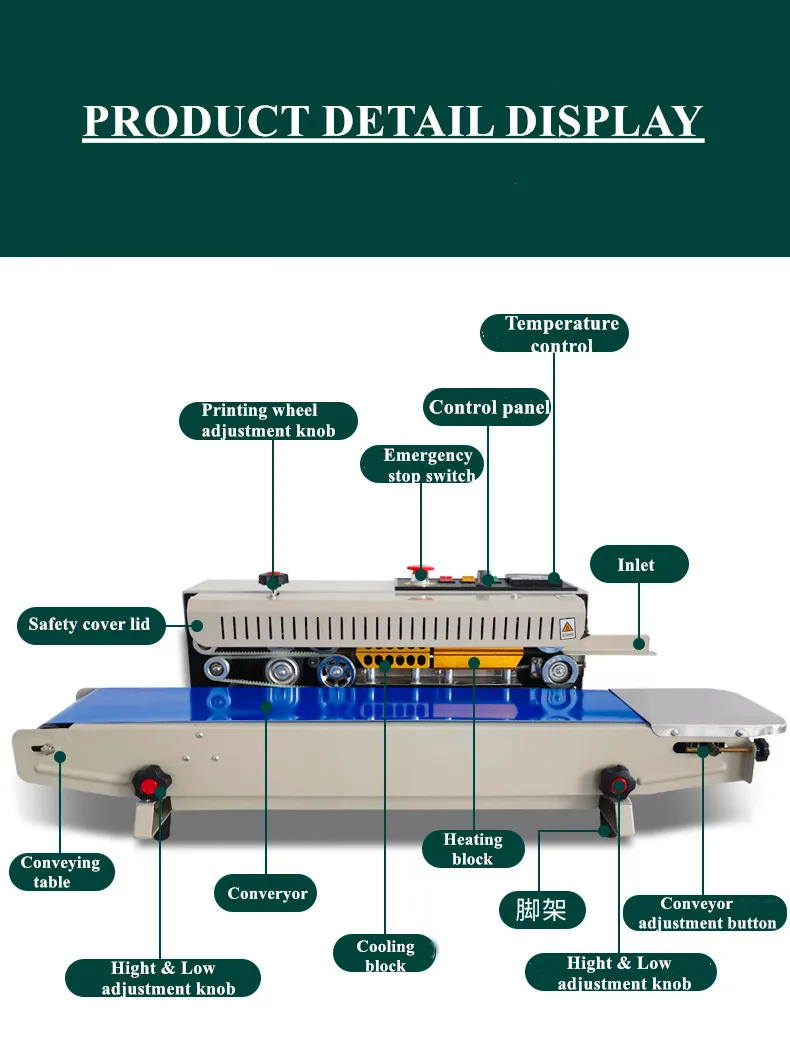

1. What is the SF-150 Horizontal Heat Poly Bag Pouch Heat Sealer?

The SF-150 is a semi-automatic horizontal heat sealer designed for continuous sealing and shrink sleeve seaming of bags and pouches. It's an electric-driven machine intended for packaging operations using paper and plastic materials.

2. What are the key technical specifications?

Dimensions: 38.5 x 27.5 x 20 cm; Weight: 20 kg; Voltage: 220V/50Hz; Power: 500W; Max speed: 16 m/min; Sealing width: 6–10 mm; Compatible film thickness: 0.02–0.8 mm; Temperature range: 0–250°C; Printing characters/support: 20 pcs; Capacity listed as 5 kg.

3. Which packaging types and materials does it support?

The machine is suitable for bags, pouches, belt and carton feeding and works with packaging materials such as paper and various plastics. For specific film chemistries (PE, PP, PET, laminated films), confirm compatibility with the supplier.

4. Is the SF-150 fully automatic?

No — the SF-150 is listed as semi-automatic. That typically means an operator feeds or positions packages but the sealing/shrinking operation runs continuously/automatically once initiated.

5. What is the sealing speed and maximum throughput?

Sealing speed is adjustable from 0 to 16 m/min, with a maximum rated speed of 16 m/min. Actual throughput depends on package size, operator feeding speed and setup.

6. What sealing width does the machine provide?

Sealing width is 6–10 mm, suitable for standard bag and pouch seals.

7. What film thickness can it handle?

Compatible film thickness range is 0.02–0.8 mm. Thicker or multilayer materials may require testing or supplier confirmation.

8. What are the electrical requirements and power consumption?

The machine requires a 220V, 50Hz electrical supply and consumes 500W during operation. Use a properly grounded and rated circuit.

9. What does the 'temperature range 0–250°C' mean in practice?

The heating element is adjustable within 0–250°C to suit different film types and sealing conditions. Proper temperature settings depend on film material and thickness; always test on sample material before production runs.

10. What does 'Printing letters 20 pcs' refer to?

This likely indicates the machine supports imprinting (e.g., batch number, date, or up to 20 characters). Check the specific model documentation or supplier to confirm printing capabilities and character size.

11. What does the 'capacity 5 kgs' specification mean?

The spec lists a capacity of 5 kg, which typically refers to the maximum recommended load related to either the conveyor or the package weight the machine is designed to handle. Confirm the exact meaning with the supplier before processing heavier packages.

12. What routine maintenance is required?

Regular maintenance includes cleaning the sealing area, checking and replacing worn heating elements, Teflon tape or sealing wires, lubricating moving parts as recommended, and ensuring electrical connections and ventilation are clear. Follow the manufacturer's maintenance schedule in the user manual.

13. Are there safety precautions I should follow?

Yes. Provide proper grounding and electrical protection, keep hands and loose clothing away from the sealing zone and moving parts, allow heating elements to cool before servicing, and use personal protective equipment as needed. Follow all safety instructions in the operator manual.

14. How do I install and set up the machine?

Place the machine on a stable, level surface near a 220V/50Hz grounded outlet with adequate ventilation. Connect to power, perform initial checks per the user manual, load test film/sample packages, and adjust speed, temperature and sealing width for optimal seals. For detailed setup, refer to the supplied manual or contact the vendor for on-site support.

15. What warranty, spare parts and after-sales support are available?

Warranty and support details are not provided in the product spec. Contact the seller or manufacturer to confirm warranty duration, availability of spare parts (heating elements, Teflon tape, print heads), technical support and training options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading