B21, China Town Mall, Midrand

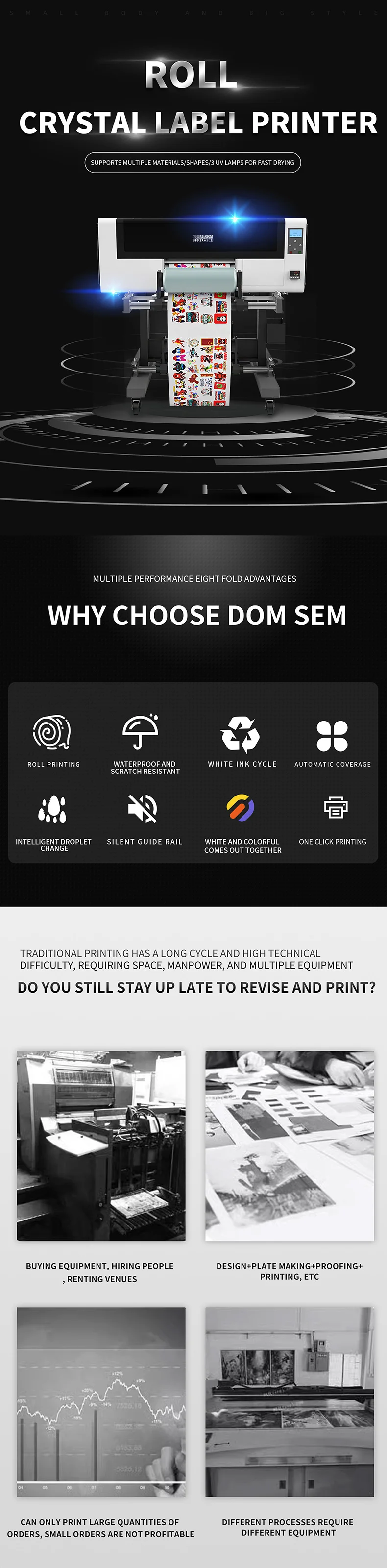

Roll to Roll UV DTF Film Sticker Printing Machine All in one UV DTF Printer

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600879800554

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the printable width of this Roll to Roll UV DTF printer?

The listed model supports a maximum printable roll width of 30 cm (approx. 300 mm). Actual printable image width may be slightly less depending on edge margins and media handling.

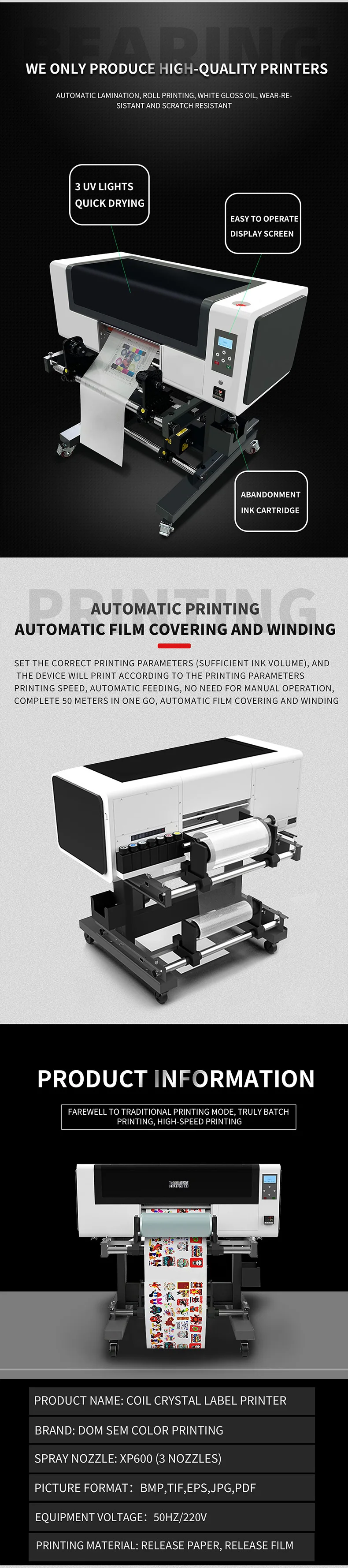

2. What printheads does this machine use?

This model is equipped with three XP600 printheads (Epson MicroPiezo style). They are designed for high-precision drop-on-demand printing and support fine detail and variable drop sizes.

3. What does 'UV DTF' mean and how does this printer work?

UV DTF refers to printing UV-curable inks onto direct-to-film (DTF) transfer film. The printer lays down UV inks onto a roll of DTF or sticker film, then cures the ink immediately with built-in UV LEDs, producing a durable print that can be transferred or used as a sticker.

4. Which inks and films are compatible with this machine?

The printer is designed for UV-curable inks formulated for DTF and sticker applications and for compatible PET-based DTF films and UV-printable vinyls. Use inks and films recommended by the supplier to ensure adhesion and curing performance.

5. Can this printer produce white ink or varnish layers?

Many all-in-one UV DTF systems offer configurable ink channels for CMYK plus white and/or clear varnish. Whether white or varnish is installed depends on the specific configuration—confirm with the seller if you need white ink or clear/coating capability.

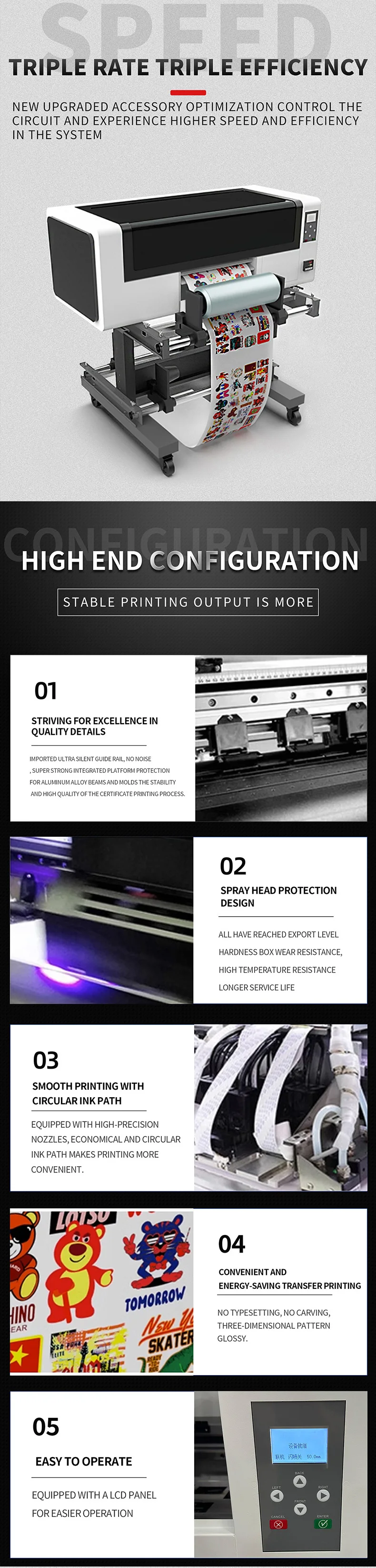

6. What print resolution and image quality can I expect?

Image quality depends on RIP settings and media, but XP600 printheads typically support high-resolution printing. You can achieve very fine detail suitable for stickers and transfers—configurable up to photo-quality resolutions depending on RIP and driver settings.

7. What printing speed can I expect?

Printing speed varies by resolution, ink curing settings and media. Typical roll-to-roll UV DTF printers operate across a range—from higher-speed draft modes to slower high-resolution modes. Ask the supplier for benchmark speeds for your target resolutions.

8. Does the machine include RIP software and what file formats are supported?

Included software varies by supplier. This machine is compatible with standard RIP packages used in industrial inkjet workflows (supporting formats like TIFF, PNG, JPEG, PDF). Confirm with the seller which RIP or driver is bundled and whether color profiles are provided.

9. How is curing handled and is post-curing needed?

The printer uses integrated UV LED lamps to cure UV inks immediately after printing. In most cases the prints are fully cured on exit and do not require additional post-curing, but follow the ink and media manufacturer instructions for optimal results.

10. What maintenance is required to keep the XP600 heads running reliably?

Regular maintenance includes scheduled head cleaning, nozzle checks, capping-station maintenance, flushes when idle for extended periods, and using recommended inks to prevent clogging. Follow the machine's maintenance schedule and supplier recommendations.

11. What consumables should I plan for?

Consumables include UV-curable inks, DTF or sticker film rolls, wiper blades, capping station rubbers, maintenance fluids (if recommended), and replacement parts like pumps or belts over time. Keep a stock of commonly used consumables to reduce downtime.

12. What are the power and environmental requirements?

Power requirements vary by configuration and region; many units run on single-phase 110–240V depending on ordered specifications. The printer should be operated in a clean, climate-controlled environment (stable temperature and humidity) per the supplier's installation guide.

13. Is the machine easy to set up and operate for someone new to DTF printing?

The machine is an all-in-one roll-to-roll solution which simplifies many steps, but initial setup, color profiling and maintenance do require trained personnel. Most suppliers offer training, installation, and operational support—ask about those services.

14. What warranty and technical support are available?

Warranty terms vary by vendor; common coverage is a limited warranty on electronic components and printheads for a specified period, excluding consumables and user-caused damage. Confirm warranty length, what it covers, and availability of local technical support and spare parts before purchase.

15. Can I print custom stickers and transfer films for garments with this printer?

Yes—this roll-to-roll UV DTF printer is intended for producing custom stickers and DTF transfer films. For garment transfers, ensure you use appropriate transfer films and follow the recommended transfer process (heat press settings, adhesives) for durable results.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading