B21, China Town Mall, Midrand

Road construction machines for Crack repairing

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600877250767

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

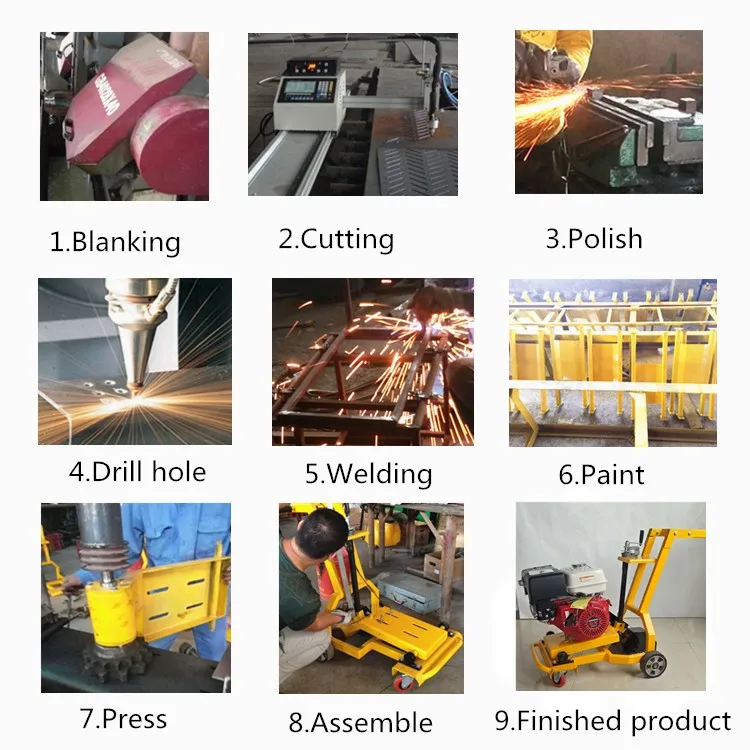

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Road Slotting Machine used for?

The Road Slotting Machine (model LS-200Slotting) is designed for precision grooving and crack preparation on asphalt and concrete surfaces — ideal for slotting prior to crack filling, sealing and joint repair.

2. What are the key technical specifications?

Model LS-200Slotting; 18 HP gasoline engine; slotting speed 5–20 m/min; cutting depth 0–80 mm; cutting width 10–50 mm; four cutting blades (blade diameter 180–200 mm); weight 156 kg; overall size 1580×750×1150 mm; moving method: pull; start: hand pull; fuel: petrol.

3. How deep and wide can the machine cut?

Cutting depth is adjustable from 0 up to 80 mm and cutting width can be set between 10 and 50 mm, allowing flexible slot sizes for different crack-repair materials.

4. What type of engine and fuel does it use?

It is powered by an 18 HP gasoline (petrol) engine with a hand pull start.

5. How many blades does it use and what are the blade dimensions?

The unit uses four cutting blades. Blade diameter compatibility is 180–200 mm. For best results use manufacturer-recommended blades matched to the surface material.

6. Is this machine suitable for both asphalt and concrete?

Yes — the machine is engineered for high-performance cutting on both asphalt and concrete surfaces for grooving and crack preparations.

7. How portable is the machine and how is it moved on site?

The machine weighs 156 kg and has compact dimensions for good maneuverability on site. It is moved by a pull method; for transport between sites a small vehicle or trailer is recommended.

8. What routine maintenance is required?

Routine maintenance includes cleaning debris after use, inspecting and tightening bolts, checking and replacing worn blades, monitoring engine oil and air filter, checking spark plug and fuel system, and lubricating moving parts. Regular checks minimize downtime and extend service life.

9. How often should I replace the cutting blades?

Blade replacement depends on material hardness, frequency of use and operator technique. Inspect blades before each shift for wear, chips or cracks and replace when cutting performance or safety is compromised. Contact your supplier for spare blades and part numbers.

10. What safety equipment and precautions are recommended?

Recommended PPE includes safety goggles or face shield, hearing protection, dust mask or respirator, cut-resistant gloves and safety boots. Always shut off the engine and disconnect spark plug before servicing, secure loose clothing, and follow local safety and emission regulations.

11. What accessories or consumables come with the machine?

Standard inclusions are not specified in the general description. Typical items may include a set of blades, basic tools and an operator manual. Contact sales for an exact list of included accessories and optional kits.

12. Can this machine be used to prepare slots for different crack sealants?

Yes — the adjustable width (10–50 mm) and depth (up to 80 mm) make it suitable for preparing slots for a variety of crack sealants and fillers. Confirm slot size requirements with your material supplier for best results.

13. Is on-site training or service available?

On-site training and after-sales service availability vary by supplier and region. Contact the manufacturer or dealer to ask about commissioning, operator training, maintenance services and spare-parts support.

14. What about noise, dust and emissions — does it comply with regulations?

The machine is powered by a gasoline engine so it will produce noise, dust and exhaust emissions. Compliance with local noise and emission regulations depends on your jurisdiction; use dust extraction or water suppression where required and wear appropriate PPE. Check with your supplier for quieter or emission-controlled engine options if needed.

15. How can I order the Road Slotting Machine or get a quote?

Please contact the manufacturer or your local dealer to request pricing, lead times, shipping options and spare parts. The sales team can also provide customized quotes, accessory bundles and information on warranty and service plans.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading