B21, China Town Mall, Midrand

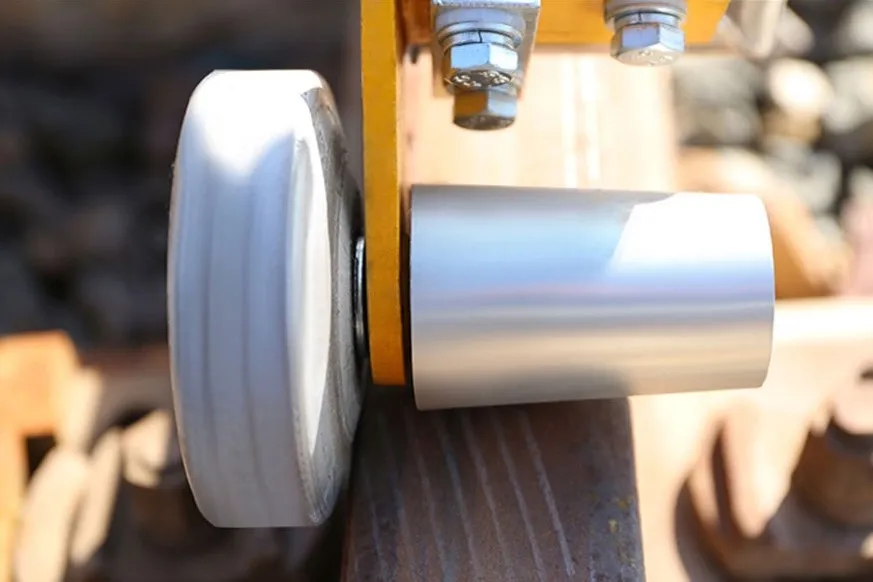

Rail and Switch Grinding Machine for railway maintenance

- Section : Sports & Entertainment

- Category : Vehicle Parts & Accessories

- SKU : 1600910392976

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model name and intended use of this machine?

This is the NCM-5.1 Rail Frog and Switch Grinding Machine, designed specifically for grinding operations on switch and crossing (frog) areas and either side of the rail head in turnouts.

2. What are the main technical specifications?

Model: NCM-5.1. Dimensions: 2100 × 1120 × 1030 mm. Engine: Honda GX270 petrol. Rated power: 5.1 kW. Grinding wheel speed: ≥ 3600 r/min. Grinding wheel feeding stroke: ≥ 80 mm. Feed adjustment accuracy: ≤ 10 mm. Grinding wheel rotation angle: ≥ 30°. Weight: ≤ 117 kg.

3. How does the grinding device adjust to work in the narrow space between rails?

The grinding device can tilt 30° left and right from vertical and the grinding wheel position can be adjusted in both vertical and horizontal directions, enabling accurate work in narrow spaces between rails.

4. What feed mechanism does the machine use and what are its benefits?

The machine uses a pull-rod transverse feed mode. This gives the operator better control of feed force, improving grinding quality and efficiency and allowing precise turning and positioning at any angle.

5. What type of power source does the machine use?

The standard power source is a Honda GX270 petrol engine (rated 5.1 kW). For other power options, contact the supplier.

6. What types and sizes of grinding wheels does the machine use?

The machine uses rail grinding wheels compatible with the machine's spindle speed (≥ 3600 r/min). Specific wheel types and sizes depend on grinding requirements — consult the supplier for approved wheel part numbers and recommended abrasive types.

7. How much does the machine weigh and how should it be transported?

Weight is ≤ 117 kg. For transport, use appropriate lifting equipment or a vehicle with sufficient loading capacity. Secure the machine and account for its dimensions (2100 × 1120 × 1030 mm). Two-person handling or mechanical assistance is recommended when lifting.

8. What routine maintenance is required?

Regularly inspect and replace grinding wheels as needed, check and tighten fasteners, keep sliding/adjustment surfaces clean and lubricated, and perform engine maintenance per the Honda GX270 manual (oil, air filter, spark plug, fuel). Also inspect guards and safety devices before use.

9. What safety precautions should operators follow?

Wear appropriate PPE (eye, ear, hand, and respiratory protection). Ensure the machine is stable and secured, keep bystanders clear of sparks and debris, shut off the engine before servicing, follow fuel-handling and fire-safety precautions, and follow local railway work safety procedures.

10. Is operator training provided or required?

Operators should be trained in safe operation, adjustment and basic maintenance of the grinder. Training and operational manuals are typically available from the manufacturer or supplier—contact them to arrange training.

11. Can the machine be used on all turnout sizes and rail profiles?

The NCM-5.1 is designed for frogs and switches and for working either side of the rail head. Compatibility with specific turnout sizes and rail profiles depends on geometry; verify suitability with the supplier and provide turnout/rail specifications if in doubt.

12. What consumables and spare parts should I keep on hand?

Typical consumables include grinding wheels, wheel nuts/spindle fittings, engine oil, air filters and spark plugs. Keep common wear parts and fasteners on hand. Contact the supplier for a recommended spare-parts list and part numbers.

13. What grinding accuracy and adjustment precision can I expect?

Feed adjustment accuracy is ≤ 10 mm and the machine provides precise positioning and turning at various angles, aided by the adjustable wheel position and 30° tilt capability. Final accuracy will depend on operator setup, wheel condition and rail condition.

14. How noisy and polluting is the machine in the field?

Noise and emissions are those typical of a petrol-engine driven grinder. Expect engine noise and grinding noise—use hearing protection and comply with local emission and noise regulations. For lower-noise/emission requirements, ask the supplier about alternative power options.

15. What warranty and after-sales support are available?

Warranty terms and after-sales support vary by supplier and region. Contact the manufacturer or your local distributor for warranty details, service contracts, spare-part availability and response times.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading