B21, China Town Mall, Midrand

Professional dtf printer a3 printing machine+dryer

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600816405445

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printable size on the Professional DTF Printer A3?

The printer supports A3-class output with a maximum print width up to 320 mm (effective printable width is typically around 300 mm depending on margins and platen setup).

2. What inks does this machine use and what does CMYK+W+W mean?

This machine uses DTF pigment ink in a CMYK+W+W configuration. That means standard CMYK color channels plus two dedicated white channels for stronger white coverage and higher opacity on dark textiles.

3. What is included in the ink delivery system?

The printer uses a continuous ink supply system (CISS), listed as a negative-pressure CISS, to provide stable pigment ink flow and reduce the need for frequent cartridge changes.

4. How fast does the printer operate?

Typical print speed is about 0.8 meters per hour, suitable for small-batch and on-demand production.

5. What is the role of the built-in dryer and the 3-phase heating platform?

The integrated dryer cures ink and helps fix adhesive powder after printing. The 3-phase heating platform (front, middle and rear) provides consistent, even heating across the film path to improve adhesion and reduce curing unevenness.

6. Is a heat press included and is it required?

A separate heat press is not included. After printing and curing on the DTF film, you will typically need a heat press to transfer the design onto garments or substrates.

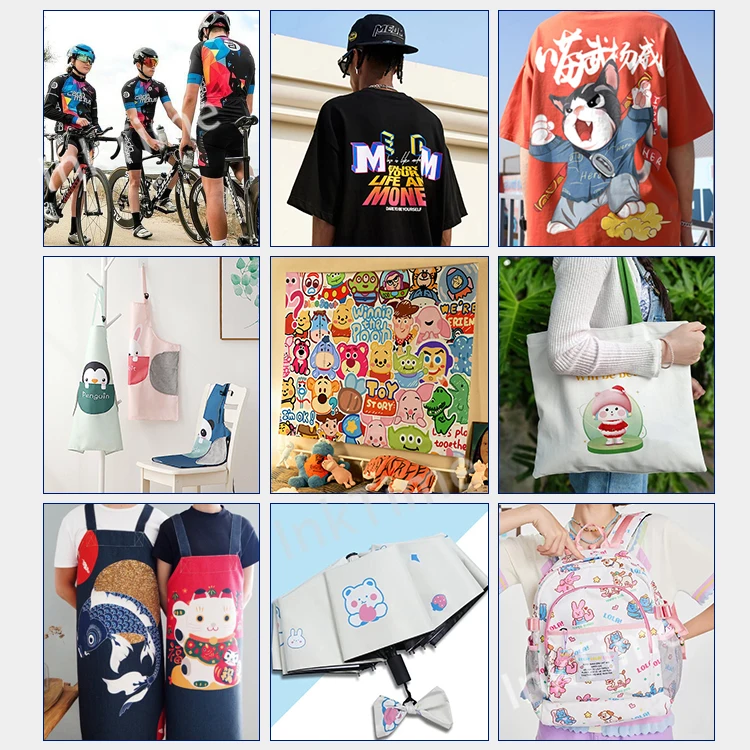

7. What materials can I print on with DTF transfers?

DTF transfers work well on a wide variety of textiles, including cotton, polyester, and blended fabrics. They can also be applied to some non-textile substrates when proper prep and transfer settings are used.

8. What file formats does the printer support?

The printer accepts common image formats such as BMP, TIFF, JPG and PDF, making it easy to integrate into most design workflows.

9. What does 'semi-automatic' operation mean for this printer?

Semi-automatic means the machine automates the printing and drying stages, while the operator handles media loading/unloading, applying powder to the prints, and the final heat-press transfer steps.

10. What are the physical dimensions and weight of the unit?

The unit measures approximately 780 x 430 x 350 mm and weighs around 65 kg, making it compact enough for small workshops or limited workspace environments.

11. What voltage options are available and do I need to configure anything?

The printer supports 110V, 220V and 380V options. Verify and select the correct voltage option for your region before installation; some models may require configuration or a dedicated power setup.

12. What maintenance is required to keep the printer reliable?

Regular maintenance includes daily/nozzle checks, periodic printhead cleaning (L1800 printhead), keeping white ink circulated to prevent clogging, topping up ink tanks, cleaning the platen and paper path, and following any manufacturer-recommended flushing or idle procedures.

13. What consumables and accessories will I need?

Common consumables include DTF pigment inks, PET transfer film, hot-melt adhesive powder, replacement printhead parts (as needed), cleaning solutions, and a heat press for final transfers.

14. What warranty and support does the product come with?

The product includes a 1-year warranty. For setup, troubleshooting and spare parts, contact the vendor or authorized support network provided at the time of purchase.

15. Who is this A3 DTF printer with dryer best suited for?

It's ideal for garment printing shops, small businesses, and creative professionals who need a compact, reliable solution for producing vibrant, durable DTF transfers for custom apparel and small-batch production.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading