B21, China Town Mall, Midrand

Precision Deep Drawing Parts Tool And Die Maker

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 62108163141

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials are used in the Precision Deep Drawing Parts Tool?

The tools are made from high-grade materials, specifically SKD11 for the die plate and P20 or as specified for the stripper plate.

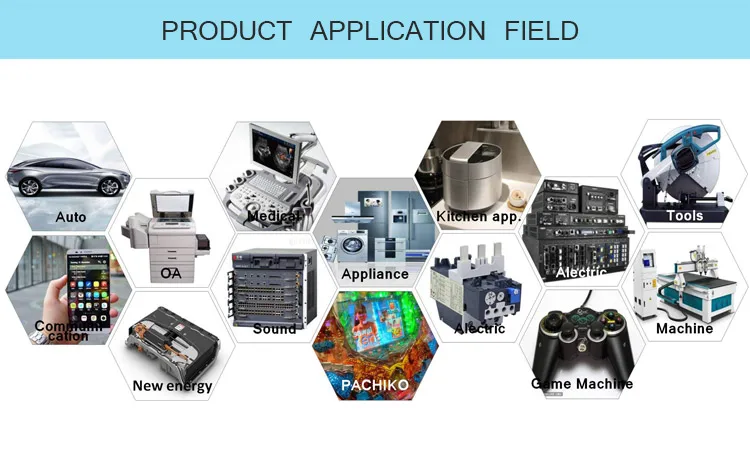

2. What industries can benefit from your deep drawing parts tool?

Our tools are suitable for various industries including automotive parts manufacturing, aerospace component production, electronics housings, home appliances, and custom prototyping.

3. How long does it take to manufacture tooling?

The tooling manufacturing cycle typically ranges from 3 weeks to 10 weeks, depending on the complexity of the project.

4. What certifications does your factory have?

Our factory is certified ISO9001, ensuring that we meet international quality management standards.

5. What design file formats do you accept?

We accept various design file formats including DWG, DXF, STEP, X_T, TOP, and IGS.

6. Can you customize the tooling to specific requirements?

Yes, we offer customized solutions tailored to meet your specific needs.

7. What is the maximum tonnage of press machines you can accommodate?

We can accommodate press machine tonnage ranging from 30T to 315T.

8. What quality control measures do you implement?

We ensure rigorous quality assurance processes throughout the manufacturing cycle to maintain high standards.

9. Is there a minimum order quantity for the tooling?

Please contact us for specific details regarding minimum order quantities, as it may vary based on the project.

10. What is the typical application for your deep drawing tools?

Typical applications include metal stamping and die making for precision components across various industries.

11. Do you provide prototypes for new designs?

Yes, we offer custom prototyping services for various industries to help develop new designs.

12. What is the color of the finished tools?

The tools are typically finished in a natural color, but custom colors can be requested.

13. How do I place an order for your precision deep drawing parts tool?

You can place an order by contacting us directly with your specifications and requirements.

14. Can you assist with design modifications during the development process?

Yes, we are happy to assist with design modifications to ensure the final product meets your expectations.

15. What experience do you have in the industry?

We have over 15 years of experience in metal stamping and die making, providing reliable and high-quality solutions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading