B21, China Town Mall, Midrand

Pet preform detect machine plastic pet bottle visual inspection detection equipment

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600804762236

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum speed of the Sunco Visual Inspection Equipment?

The Sunco Visual Inspection Equipment has a maximum speed of 1200 branches per minute, ensuring high throughput for your production line.

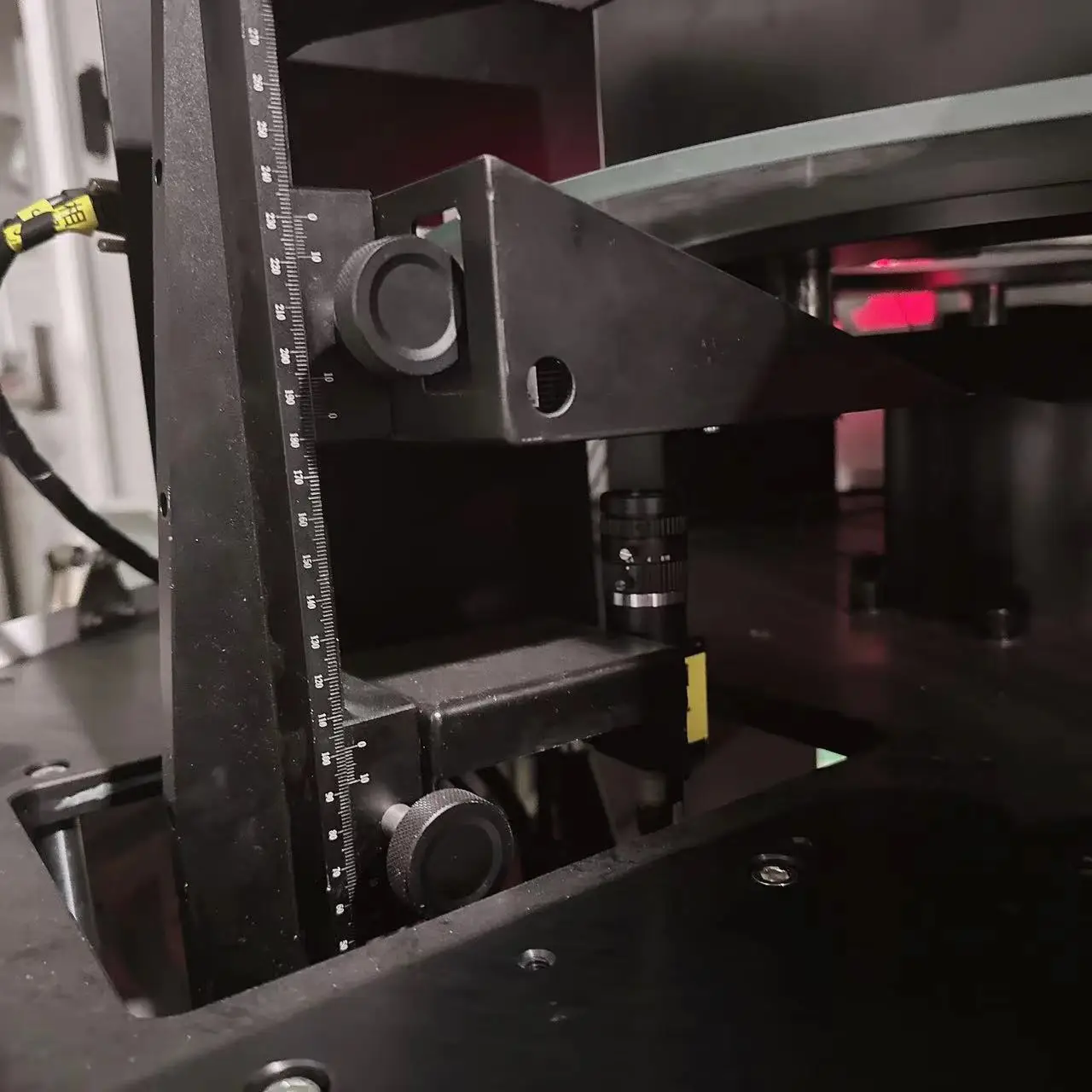

2. What is the accuracy level of the inspection process?

The equipment offers exceptional precision with accuracy levels up to ±0.01mm, making it ideal for high-precision inspection tasks.

3. What types of products can this machine inspect?

This machine is suitable for inspecting rubber rings, screws, mobile phone accessories, and plastic products, including pet bottles.

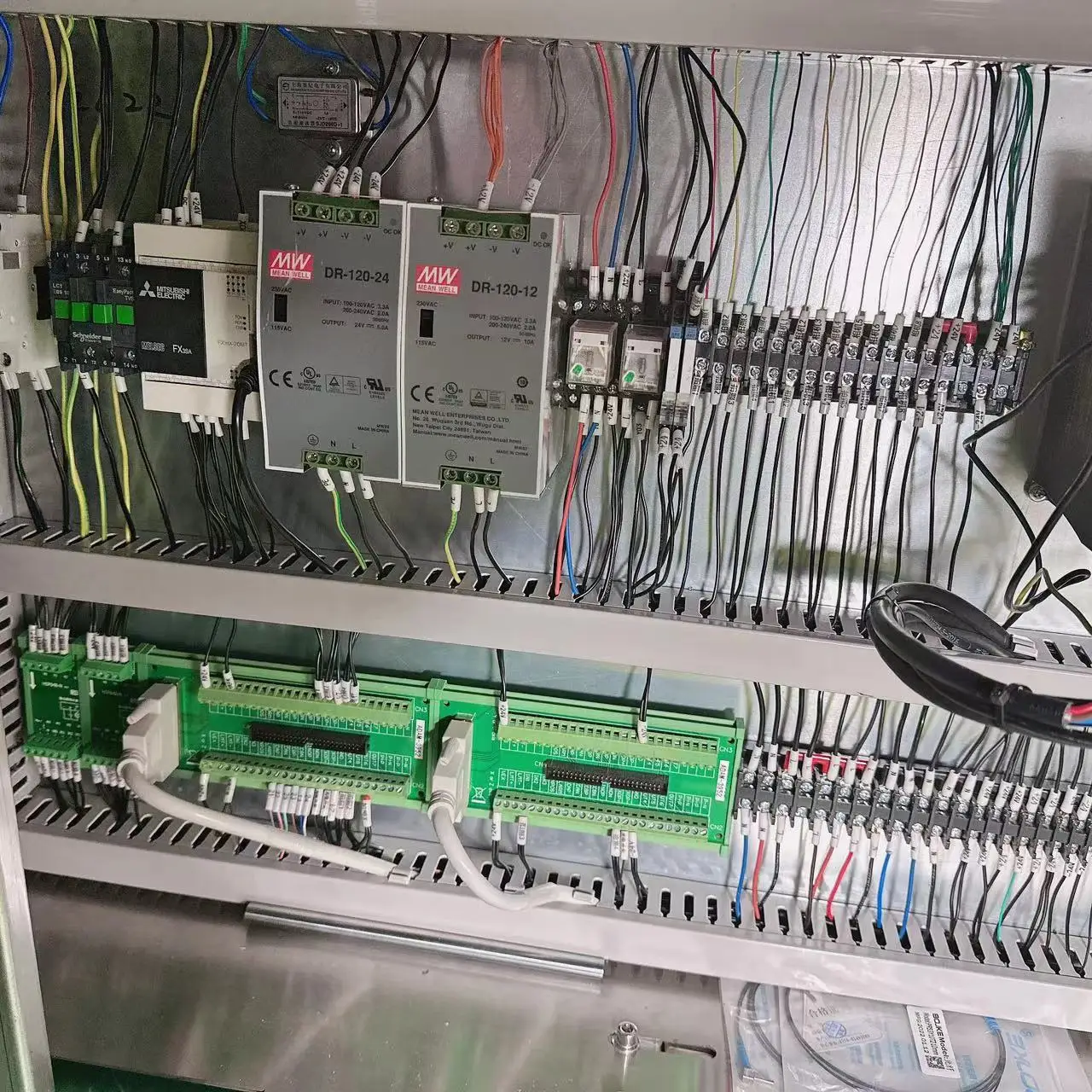

4. What power supply is required for the machine?

The Sunco Visual Inspection Equipment operates on an electronic power supply with a voltage of AC 220V and a frequency of 50Hz.

5. What are the dimensions of the equipment?

The machine has a compact design with dimensions of 1000mm (Length) x 1000mm (Width) x 1900mm (Height).

6. What is the weight of the Sunco Visual Inspection Equipment?

The equipment weighs approximately 550kg.

7. Does the machine come with a warranty?

Yes, the Sunco Visual Inspection Equipment comes with a 1-year warranty on core components, providing peace of mind for extended use.

8. What types of defects can this machine detect?

The machine is capable of detecting dimension issues, mixing problems, deformation, missing material, burrs, and black spots.

9. Is there a video inspection report provided?

Yes, an outgoing video inspection and machinery test report are provided for quality assurance.

10. What are the operating temperature ranges for the machine?

The operating temperature range for the machine is -3℃ to 45℃, while the storage temperature range is -20℃ to 60℃.

11. What type of camera system does the machine use?

The Sunco Visual Inspection Equipment is equipped with a high magnification CCD industrial camera, a Japanese lens, and a professional light source system.

12. How does the feeding system work?

The feeding system includes a dedicated feeding guide line and a vibration feeder for automatic feeding, with optional container devices available.

13. What is the inspection speed for pet bottle preforms?

The machine can inspect pet bottle preforms at a speed of up to 200 per minute, depending on the specific requirements.

14. Can the machine be customized for specific inspection needs?

Yes, the Sunco Visual Inspection Equipment can be tailored to meet specific inspection requirements through OEM machine vision inspection systems.

15. Is the machine suitable for food and beverage manufacturing?

Yes, the Sunco Visual Inspection Equipment is an ideal solution for manufacturing plants and food & beverage factories that require high-speed, high-precision inspection.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals