B21, China Town Mall, Midrand

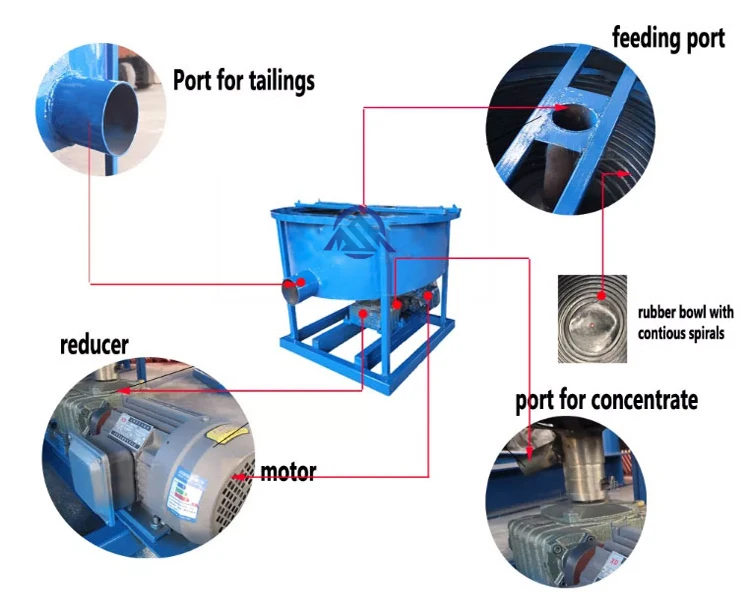

Mineral Separator Gold Concentrator Centrifugal Gravity Concentrator Gold Mining equipment

- Section : Machinery

- Category : Construction Machinery

- SKU : 1601046161577

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this Mineral Separator / Centrifugal Gravity Concentrator used for?

It is designed for recovery of alluvial gold and other high-density minerals (e.g., tungsten sand, tin sand). It replaces chutes and manual panning for small-scale mining, field geological investigation, laboratory heavy-sand separation and use on gold dredgers.

2. What are the key technical specifications of this concentrator?

Disc diameter: 600 mm; Working speed: 100–180 r/min; Power: 1.1 kW; Dimensions: 1000 × 800 mm; Weight: 155 kg; Feeding size: ≤3 mm; Capacity: 3–7 m³/h; Typical feeding time per batch: 20–40 min.

3. How does the centrifugal concentrator work?

The inclined rotating bowl generates centrifugal force, friction, gravity and hydrodynamic forces that stratify particles by density. Heavier minerals migrate to concentrate zones and are discharged separately from tailings.

4. What feed material size and concentration does it accept?

Recommended maximum feed particle size is 3 mm. The machine is intended for slurry feeds typical of alluvial deposits; optimal feed concentration and slurry density should be determined during test runs for each deposit.

5. What is the processing capacity?

Typical capacity ranges from 3 to 7 m³/h depending on feed grade, particle size distribution, slurry density and operating speed.

6. What power and drive options are available?

Standard drive is an AC motor powered by a 1.1 kW motor. It can also be powered by a diesel generator for field or remote operation.

7. How should I install and set up the concentrator?

Mount on a stable, level foundation or frame, ensure secure mechanical and electrical connections, connect appropriate slurry feed and tailings discharge, and set rotational speed within 100–180 r/min. Follow supplier installation guidelines and local electrical codes.

8. How often should the machine be cleaned and maintained?

Perform routine inspections before each shift. Clean the bowl and concentrate discharge after each feed cycle or at least daily. Check bearings, seals, fasteners and drive components regularly and lubricate per supplier recommendations.

9. What are the main advantages compared with sluices or manual panning?

Higher separation efficiency, better recovery of fine gold, reduced labor intensity and more consistent, repeatable results. It also works well on other dense minerals that sluices may miss.

10. Can this concentrator be integrated with dredgers or larger processing setups?

Yes. The design is commonly combined in various configurations on gold dredgers and in modular plant layouts. Contact the supplier with your flow rate and dredge specs for integration options.

11. What safety precautions should be observed during operation?

Ensure all guards are in place around moving parts, use proper lockout/tagout procedures for maintenance, avoid overloading the unit, wear appropriate PPE when handling concentrates, and follow electrical safety practices.

12. What spare parts and consumables should I keep on hand?

Common spares include bowl liners or mats, seals and gaskets, bearings, belts (if applicable), and electrical components. Keep a small stock of fasteners and wear parts for quick replacement.

13. Do you offer training, commissioning or after-sales technical support?

Most suppliers provide commissioning support, operator training and technical assistance. Contact the seller to confirm the level of on-site or remote support available.

14. Is customization available (e.g., different disc sizes, drive options or multi-unit systems)?

Yes — many combinations are used in the field. Suppliers typically offer customized drive options, mounting frames and multi-unit setups to meet capacity or dredge integration requirements. Discuss your project needs with the manufacturer.

15. What are the warranty, shipping and procurement details?

Warranty terms, lead times and shipping arrangements vary by supplier. Ask the vendor for specific warranty coverage, packaging, shipping options, export documentation and estimated delivery times for your location.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading