B21, China Town Mall, Midrand

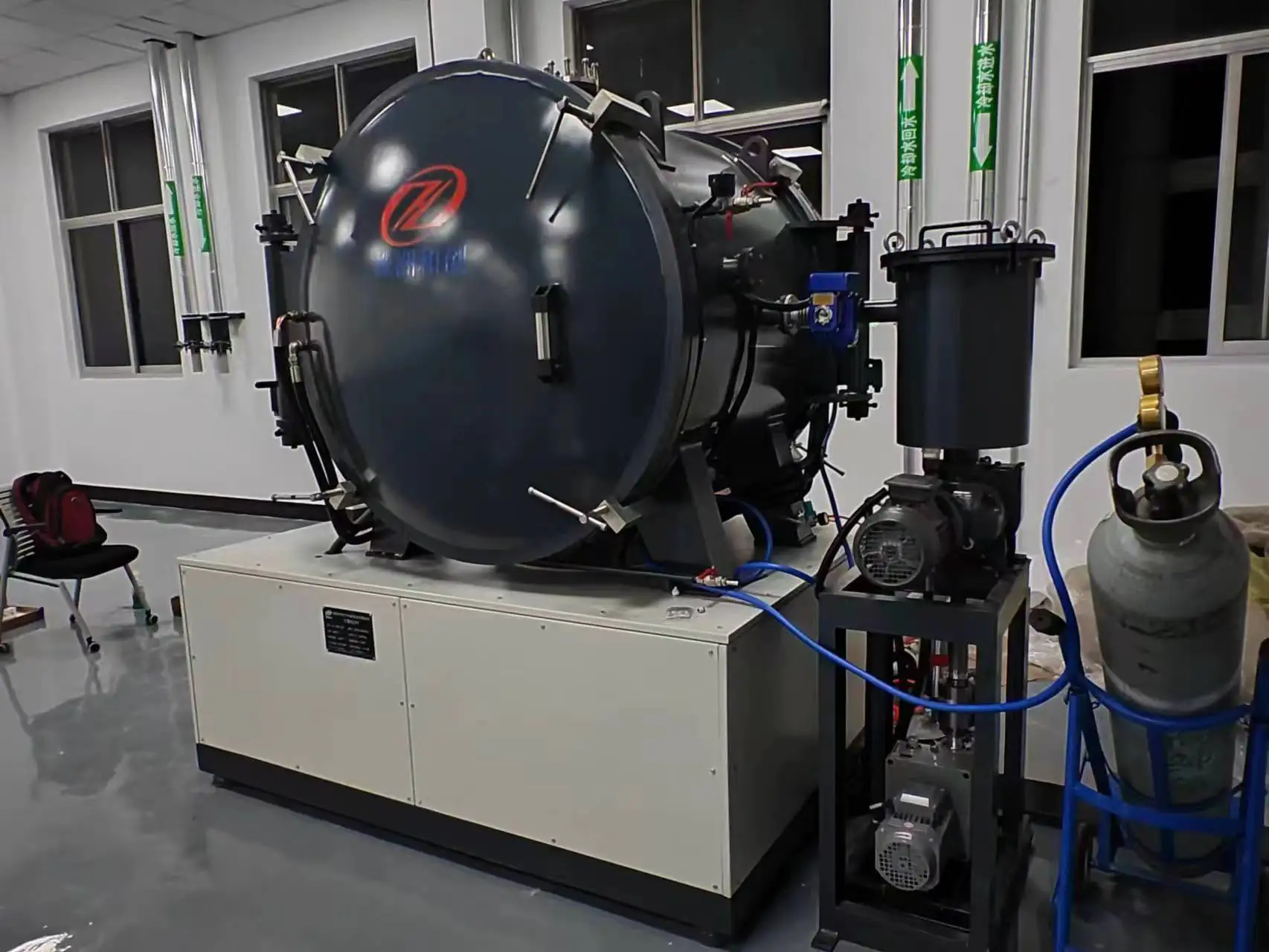

Metal Organic Compound Hydrocarbons Vacuum vapor Deposition Furnace Under Specific Pressure

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1601205296914

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main purpose of the Metal Organic Compound Hydrocarbons Vacuum Vapor Deposition Furnace?

The main purpose of this furnace is to create high-quality composite materials using advanced vacuum vapor deposition technology.

2. What materials are used in the construction of the furnace?

The furnace is made of high-quality 316L stainless steel and may also have Teflon coatings, ensuring excellent corrosion resistance and airtightness.

3. What are the heating modes available for this furnace?

The furnace uses graphite resistance heating for effective and efficient temperature control during the deposition process.

4. Can the furnace be operated remotely?

Yes, the furnace features a remote monitoring interface that allows for real-time status checks and operational oversight from a PC.

5. What is the maximum working temperature of the furnace?

The maximum working temperature of the furnace is 1650°C, making it suitable for a variety of high-temperature applications.

6. What is the effective volume of the furnace models?

The effective volume varies by model, ranging from 30x30x40 cm to 75x75x200 cm, accommodating different production needs.

7. What types of applications is this furnace suitable for?

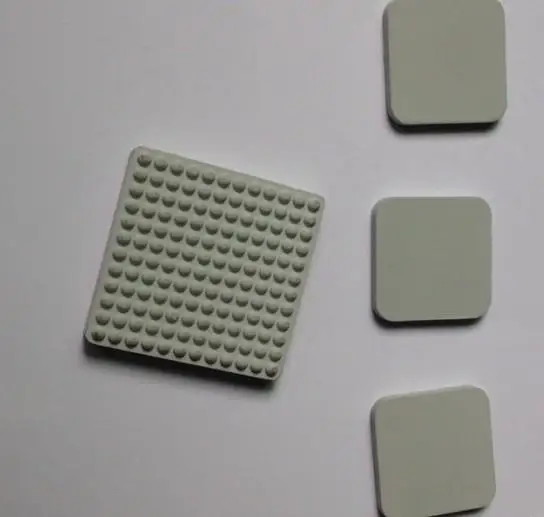

This furnace is suitable for CVD treatment of C/C and SiC composites, research in composite material development, and production of high-quality coatings.

8. What is the ultimate vacuum level that the furnace can achieve?

The furnace can achieve an ultimate vacuum of 6.67 x 10^-2 Pa in the cold state, which can be customized as needed.

9. How does the furnace ensure uniform deposition of materials?

The furnace includes a unique rotation unit that ensures uniform deposition of materials throughout the deposition process.

10. Is the furnace easy to operate?

Yes, the furnace features a high degree of automation with fully automatic temperature control and an intuitive control system for water, electricity, and gas.

11. What is the loading capacity of the different furnace models?

The loading capacity varies by model, ranging from 36 g to 1125 g, allowing flexibility based on production requirements.

12. What is temperature uniformity like in this furnace?

The furnace has a temperature uniformity range of ±10 to ±30°C, ensuring stable and consistent deposition conditions.

13. What features contribute to the safety of the furnace?

The furnace includes a fully automatic control and protection system for water, electricity, and gas, enhancing operational safety.

14. Can the furnace handle corrosive gases and solid dust?

Yes, the furnace is designed to effectively collect and treat corrosive tail gas and solid dust, ensuring a safe operating environment.

15. Is this furnace suitable for both experimentation and production?

Yes, the furnace is versatile, making it suitable for both experimental setups and large-scale production in advanced materials labs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading