B21, China Town Mall, Midrand

Magnetic Separator by Victory

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600217853324

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Magnetic Separator by Victory used for?

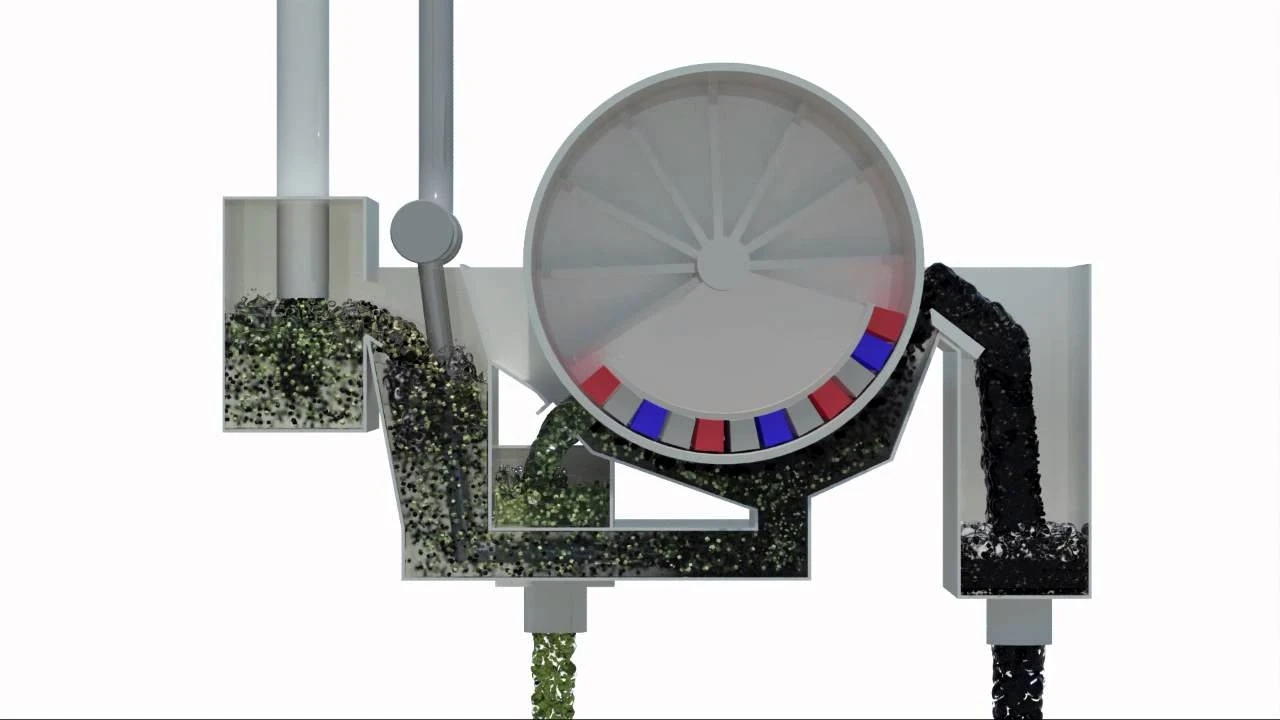

The Magnetic Separator by Victory is designed for efficient ore concentration and is used to separate magnetically different substances in mining and other industries such as ceramics, chemical, food, wood and building materials.

2. Which materials can this magnetic separator process?

It can separate magnetic minerals such as magnetite, hematite, ilmenite, pyrrhotite, roasted ore and manganese ore, and is also used for iron removal from coal, non-metallic minerals and various building materials.

3. Is the Magnetic Separator suitable for wet or dry separation?

Yes — the machine is suitable for both wet and dry magnetic separation, depending on the model and process setup.

4. What particle size range can it handle?

The separator is suitable for materials with particle sizes up to 50 mm (particles smaller than 50 mm).

5. What are the key features that improve separation performance?

Key features include a rare-earth composite magnetic system for optimized field distribution, a specially designed tank to reduce blockages, high separation efficiency, and automatic operation for consistent processing.

6. Is the machine automatic or does it require constant operator control?

The Magnetic Separator by Victory is designed for automatic operation to simplify workflows, though operator oversight is recommended during startup, changeovers and maintenance.

7. Can the separator be customized to fit my plant requirements?

Yes. The Magnetic Separator is available in various sizes and custom dimensions to meet specific model and plant layout requirements.

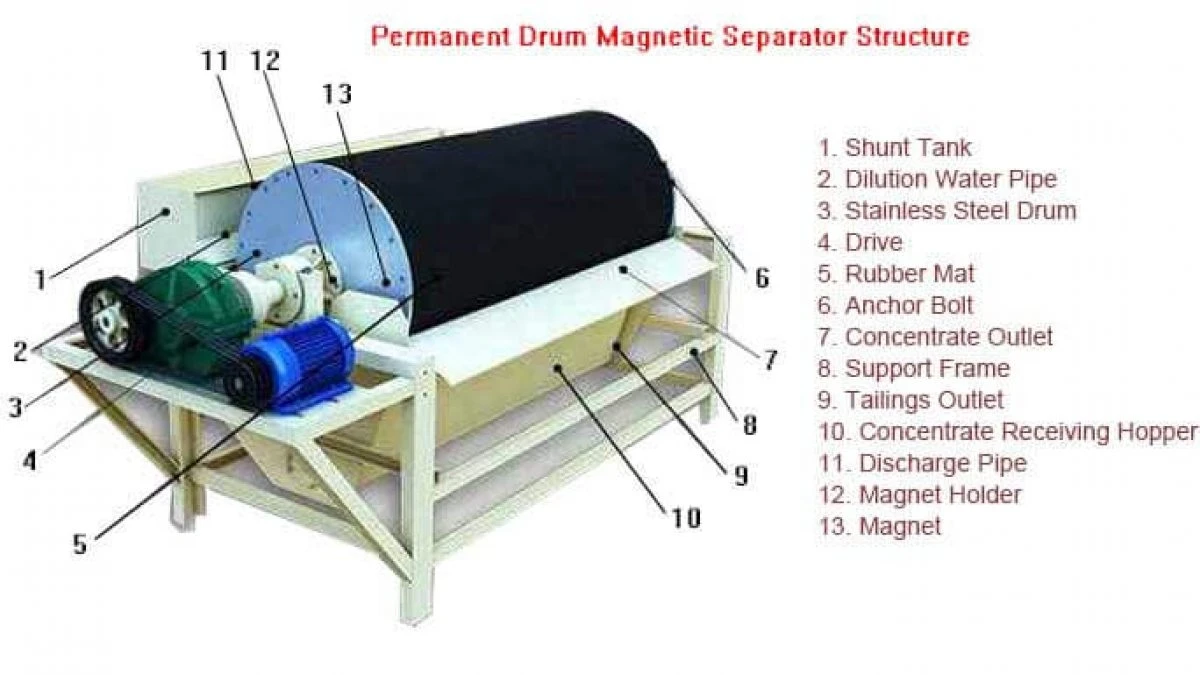

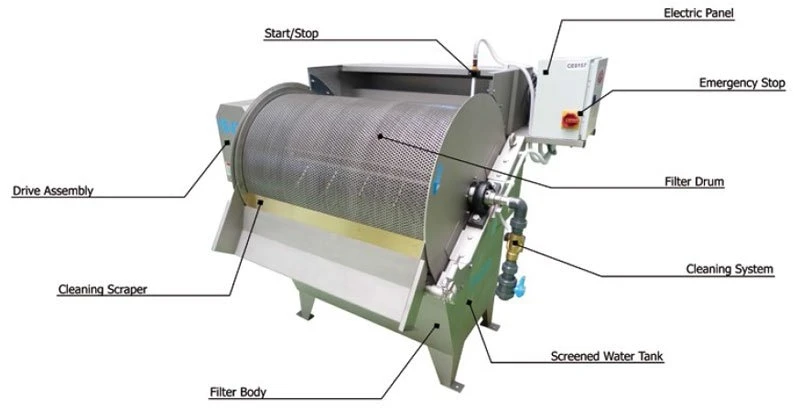

8. What kind of construction and components does the machine use?

The unit is built with robust, industrial-grade components including bearings, motors, gears and engines to ensure reliable long-term operation.

9. What installation and commissioning support does Victory provide?

Victory offers comprehensive after-sales support including video technical support and online assistance. For site commissionings or complex installs, contact Victory for specific arrangements.

10. Are spare parts available and is there any spare parts support?

Yes. Victory provides free spare parts support as part of its after-sales service; for larger spare parts requirements or long-term inventories, discuss options with your Victory representative.

11. What routine maintenance is required?

Regular maintenance typically includes inspecting and lubricating bearings and gears, checking motor performance and fasteners, cleaning the tank and magnetic system to prevent blockage, and following the manufacturer’s maintenance schedule.

12. How does product performance vary with feed characteristics?

Separation efficiency depends on feed size, moisture content, mineralogy and feed rate. Optimal performance is achieved when feed conforms to recommended size and flow parameters and when the magnetic system is matched to the target mineral.

13. Can the separator be integrated into an existing processing line?

Yes. Its customizable dimensions and automatic operation make it suitable for integration into existing concentrating plants. Provide layout and process details to Victory for proper integration planning.

14. What safety features or precautions should be considered?

Standard industrial safety measures should be applied: guarding of moving parts, emergency stop switches, lockout/tagout for maintenance, and operator training. Victory’s technical support can advise on site-specific safety measures.

15. How can I get detailed technical specifications, pricing, or warranty information?

For detailed specifications, pricing and warranty terms, contact Victory or an authorized dealer with your process requirements and preferred model; they will provide model-specific documentation and commercial details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading