B21, China Town Mall, Midrand

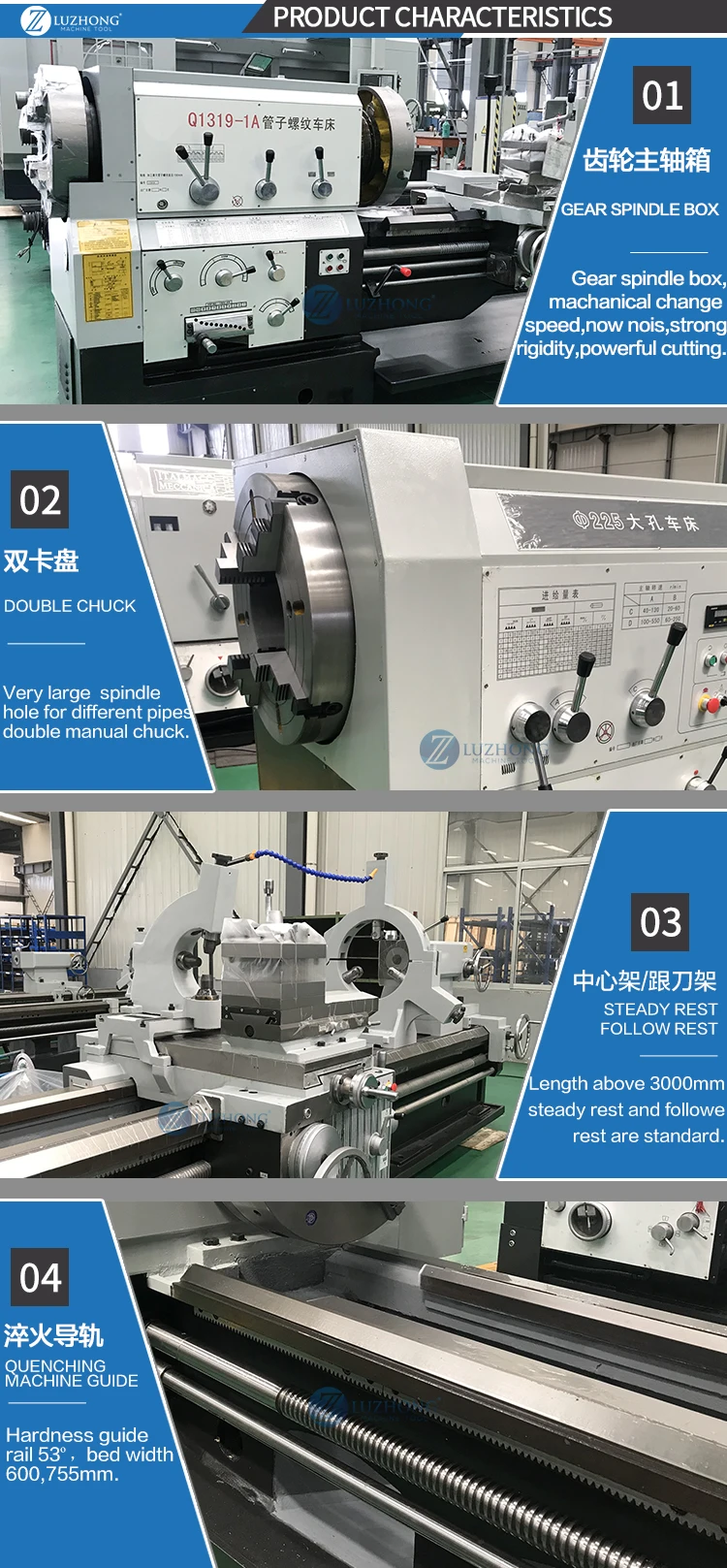

LUZHONG Q1322 Heavy Duty Pipe Threading Machine Tool CNC Lathe

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1600215374685

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LUZHONG Q1322 Heavy Duty Pipe Threading Machine Tool CNC Lathe designed for?

The Q1322 is a heavy‑duty CNC lathe optimized for pipe turning and threading operations, offering high rigidity and accuracy for large workpieces in metalworking, oil & gas, mechanical manufacturing and other industrial applications.

2. What pipe and workpiece sizes can it handle?

Pipe threading range: 50–220 mm. Two frame/capacity variants are available (select model): swing over bed 630 mm or 800 mm, swing over cross slide 340 mm or 520 mm, and distance between centers 1500 mm or 3000 mm. Maximum load capacity: 3000 kg.

3. What are the spindle specifications?

Spindle speed range is 20–550 RPM (VF, 4 steps). Spindle bore is 230 mm. The main spindle motor is 11 kW. Standard chuck is φ520 mm 4‑jaw manual.

4. What threading types and ranges are supported?

Metric threads: 1–15 mm. Inch threads (TPI): 14–1. The machine is configured for a wide range of common metric and imperial thread pitches used in pipe and shaft work.

5. What are the X and Z axis travels, feeds and rapid rates?

X axis travel: 320 mm or 420 mm (model dependent). Z axis travel: 1350 mm or 2850 mm. X axis feed steps/range: r22 / 0.02–0.45 mm/rev. Z axis feed steps/range: r26 / 0.07–1.33 mm/rev. Rapid traverse: X = 2300 mm/min, Z = 4000 mm/min.

6. Is the turret automated or manual and what tooling sizes does it accept?

The supplied tool post is a manual 4‑position turret. Tool shank size is 32 x 32 mm. Additional or powered turrets may be available as optional upgrades—confirm with the supplier.

7. What are the tailstock specifications?

Tailstock quill diameter: 100 mm. Taper: MT5. Tailstock quill travel: 250 mm.

8. What are the machine's power and motor details?

Main spindle motor: 11 kW. Rapid traverse motor: 0.3 kW. Coolant pump motor: 0.125 kW. Supply voltage and exact electrical configuration can be customized to match your workshop power (confirm required phase and voltage with the manufacturer).

9. How much does the machine weigh and what are the overall dimensions?

Weights: ~4500 kg for the 1500 mm center version and ~5700 kg for the 3000 mm center version. Dimensions: 1500 mm center model ≈ 3700 x 1650 x 1550 mm; 3000 mm center model ≈ 5200 x 1650 x 1550 mm.

10. How is the machine packaged and shipped?

Units are securely packed in plywood cases for transportation. Due to the machine's weight and size, shipping generally requires heavy lifting equipment (crane/forklift) and appropriate transport vehicles—confirm logistics with your freight provider.

11. What are the installation requirements?

Because of its mass and precision requirements, the Q1322 should be placed on a solid, level concrete foundation or appropriately rated machine base. Professional installation and alignment are recommended, including anchor bolts and proper electrical hookup by a qualified electrician.

12. What maintenance is required to keep the machine running reliably?

Routine maintenance includes regular lubrication of guideways and lead screws, keeping coolant clean and topped up (coolant pump 0.125 kW), inspecting and tightening fasteners, checking chuck and spindle condition, and scheduled inspection of electrical components. Follow the manufacturer's maintenance schedule for intervals and procedures.

13. Can the machine be customized or fitted with optional accessories?

Yes—voltage and color are customizable per the product description. Additional options commonly offered (subject to supplier availability) include different chucks, powered/tool turrets, steadies, specialized tooling and control packages. Contact the supplier for available options and pricing.

14. What safety features and operator training are recommended?

Standard safety practice includes the use of guards, emergency stop devices, proper machine grounding and operator PPE (eye protection, gloves when appropriate, no loose clothing). Verify the machine's configured safety features with the supplier. Operator training on CNC controls, safe setup, threading operations and maintenance is strongly recommended.

15. Where can I get spare parts, service, and warranty information?

For spare parts, service, warranty terms and lead time, contact the authorized LUZHONG dealer or the manufacturer's sales/support team. Exact warranty coverage and after‑sales service options vary by seller and region, so request the official documentation prior to purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading