B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

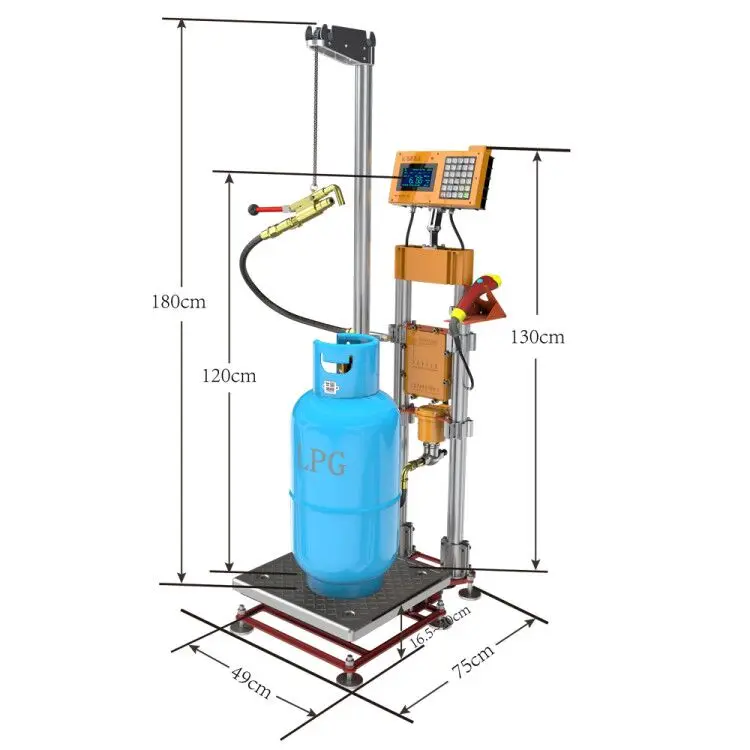

1. What is the capacity range of the LPG Cooking Gas Filling Scale?

The scale is available in two capacity ranges: 2 kg–120 kg or 2 kg–180 kg, depending on the model chosen.

2. What is the weighing accuracy and resolution?

Resolution (division) is 50 g, suitable for quantitative filling of LPG cylinders within the stated capacity range.

3. Does the filling machine stop automatically when the target weight is reached?

Yes. The machine provides quantitative filling with automatic cut-off once the preset weight is reached.

4. Is the system explosion-proof and safe for use in hazardous areas?

Yes. The device is intrinsically safe and explosion-proof with a rating of Ex ib II CT4 Gb and holds ATEX and CNEX certifications.

5. What power options does the scale support?

Primary power supply is AC 220 V, 50/60 Hz. It also includes an internal lithium battery that can power the unit for up to 15 days after charging (battery type: lithium).

6. How is the operator interface and is it easy to use?

The unit features a friendly keyboard with one-button direct operation, one-key setting, and a large LCD screen for easy and convenient operation.

7. Can the system read cylinder barcodes and integrate with inventory systems?

Yes. The system supports barcode scanning of gas cylinders (both 1D and 2D codes). Wireless data transmission is available as an optional feature for integration with back-end systems.

8. What are the operating and storage temperature/humidity ranges?

Typical operating temperature for wireless components is 0–40°C and storage temperature is −10–60°C. The PDA scanner operates from −10–55°C. Relative humidity ranges specified for components are generally 10%–90% (PDA: 20%–90% RH).

9. What are the PDA scanner specifications?

The PDA runs Android 7.1 with a 4" HD LCD (800×480), Qualcomm 8909 1.2 GHz quad-core CPU, Bluetooth 4.0 LE, Wi‑Fi 802.11 b/g/n, Type‑C USB, supports 1D/2D barcode scanning, size ~160×70×24 mm, weight ~350 g.

10. Does the machine automatically tare the filling gun and bottle weight?

Yes. The system provides automatic tare for the filling gun and bottle weight to ensure accurate net-fill measurements and convenient operation.

11. Is wireless data transmission included or optional?

Wireless data transmission is an optional feature. The product details include an optional wireless base (receiver) and a communication server (XK‑6000) for networked setups.

12. What maintenance and calibration are required?

Routine maintenance includes keeping the scale clean and dry, inspecting hoses and fittings, verifying electrical and safety connections, and periodic calibration. Follow the manufacturer's instructions and local regulations; many commercial installations require periodic (for example annual or usage-based) calibration checks.

13. Are spare parts and service available?

Yes. Replaceable spare parts such as the wireless base, communication server, PDA scanner and other detailed parts are available. Contact the supplier or authorized service center for part numbers and availability.

14. What safety and installation recommendations should I follow?

Install the scale on a stable, level surface, connect to the specified 220 V supply, use only certified intrinsically safe accessories in hazardous areas, ensure adequate ventilation, and follow local LPG handling regulations. Regularly inspect explosion‑proof seals and grounding. Refer to the installation manual for detailed instructions.

15. What certifications and quality standards does the product meet?

The LPG filling scale is certified to ATEX and CNEX standards for hazardous locations and is produced under an ISO 9001 quality management system.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading