B21, China Town Mall, Midrand

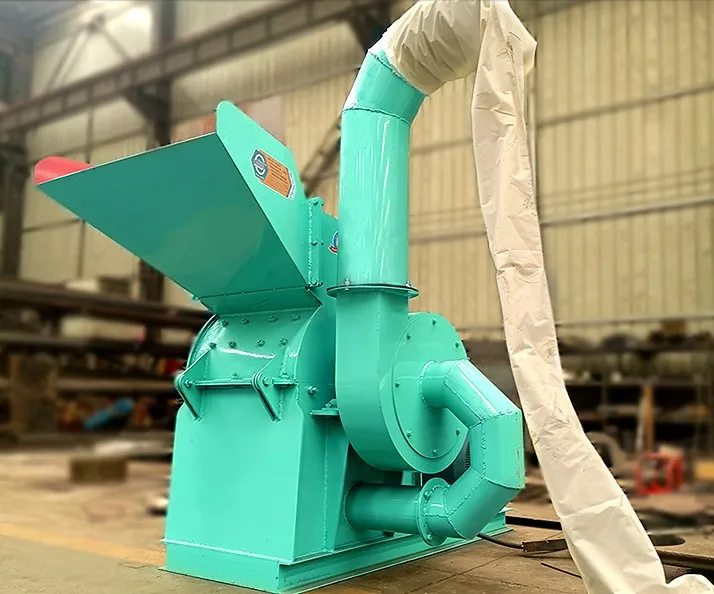

Low cost Wood Chipper Pulverizer Wood Pellet Mill Machine Tree Branch Shredder Wood Into Sawdust Machine

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 1600869970310

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Low Cost Wood Chipper Pulverizer?

The primary function of the Low Cost Wood Chipper Pulverizer is to shred or crush wood materials into smaller pieces, making it suitable for wood processing, biomass fuel production, and creating wood pellets.

2. What types of wood materials can be processed with this machine?

This machine can process a variety of wood materials, including softwood, hardwood, wood chips, sawdust, and wood shavings.

3. How does the wood hammer mill achieve different particle sizes?

The wood hammer mill allows adjustment of the screen size covering the discharge outlet, which determines the particle size of the wood produced. Different screen sizes can create different particle sizes for various applications.

4. What is the typical operating speed of the wood hammer mill?

The wood hammer mill operates at high speeds, typically ranging from 1,800 to 3,600 RPM.

5. Is regular maintenance required for the wood hammer mill?

Yes, regular maintenance is essential to keep the wood hammer mill functioning properly. This includes cleaning the machine, checking for wear on the blades and screens, and lubricating moving parts.

6. What are the environmental benefits of using this wood hammer mill?

Using this wood hammer mill helps reduce waste by converting wood scraps into usable products, promoting sustainability and conserving natural resources.

7. Can the wood hammer mill process large volumes of wood quickly?

Yes, the wood hammer mill is designed for efficiency and can process large volumes of wood materials quickly, reducing processing time and labor costs.

8. What are the dimensions and weight of the wood hammer mill?

The dimensions and weight vary by model. For example, the 600 model has dimensions of 2.4*1.2*1.4m and weighs 1500 kg, while the 1500 model measures 3.5*1.2*1.6m and weighs 5500 kg.

9. What power options are available for the wood hammer mill?

The wood hammer mill is available in various power options, ranging from 37 kW to 132 kW, depending on the model.

10. What are the advantages of using a wood hammer mill?

The advantages include size reduction for easier handling, versatility in processing different wood materials, efficiency in processing volume, customization for specific needs, durability, and environmental benefits.

11. Can the wood hammer mill be customized for specific processing requirements?

Yes, the wood hammer mill can be customized to meet specific requirements such as desired particle size, feed rate, and moisture content.

12. What types of products can be created using the wood hammer mill?

Products created can include wood pellets for fuel, animal bedding, wood flour for composite materials, and other wood-based products.

13. How does the wood hammer mill contribute to biomass fuel production?

By shredding and reducing wood materials into small particles, the wood hammer mill facilitates the production of biomass fuel, making it easier to use for energy generation.

14. Is the wood hammer mill suitable for commercial use?

Yes, the wood hammer mill is designed for heavy use and is suitable for commercial applications in wood processing industries.

15. What safety features are included with the wood hammer mill?

Safety features typically include emergency stop buttons, protective covers, and safety guards to prevent accidents during operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals