B21, China Town Mall, Midrand

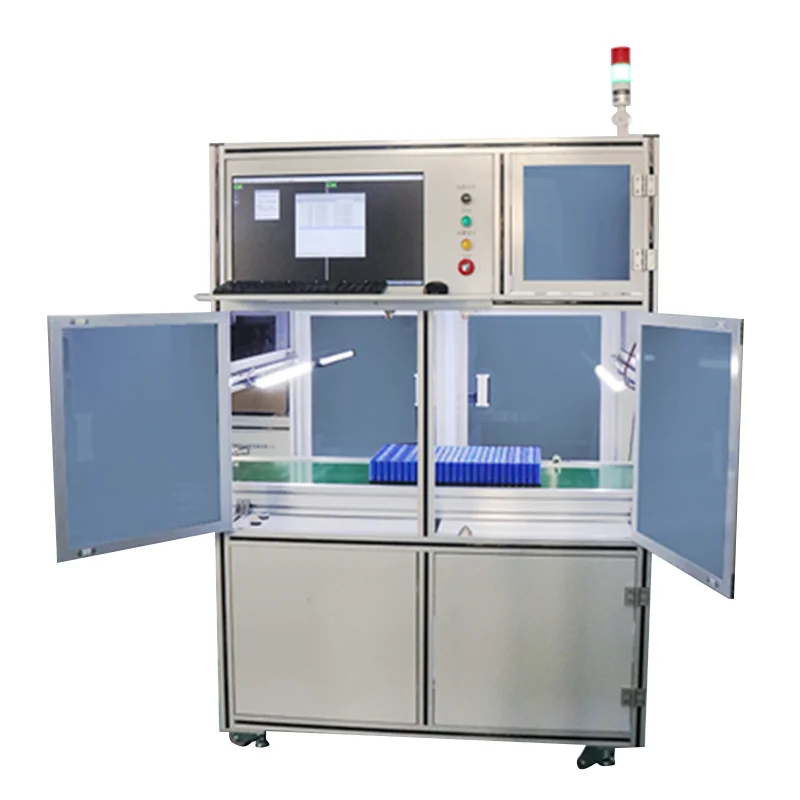

Li-ion Cell Battery Pack Production: Assembly Line Equipment for Battery Processing

- SKU : 1600133465251

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

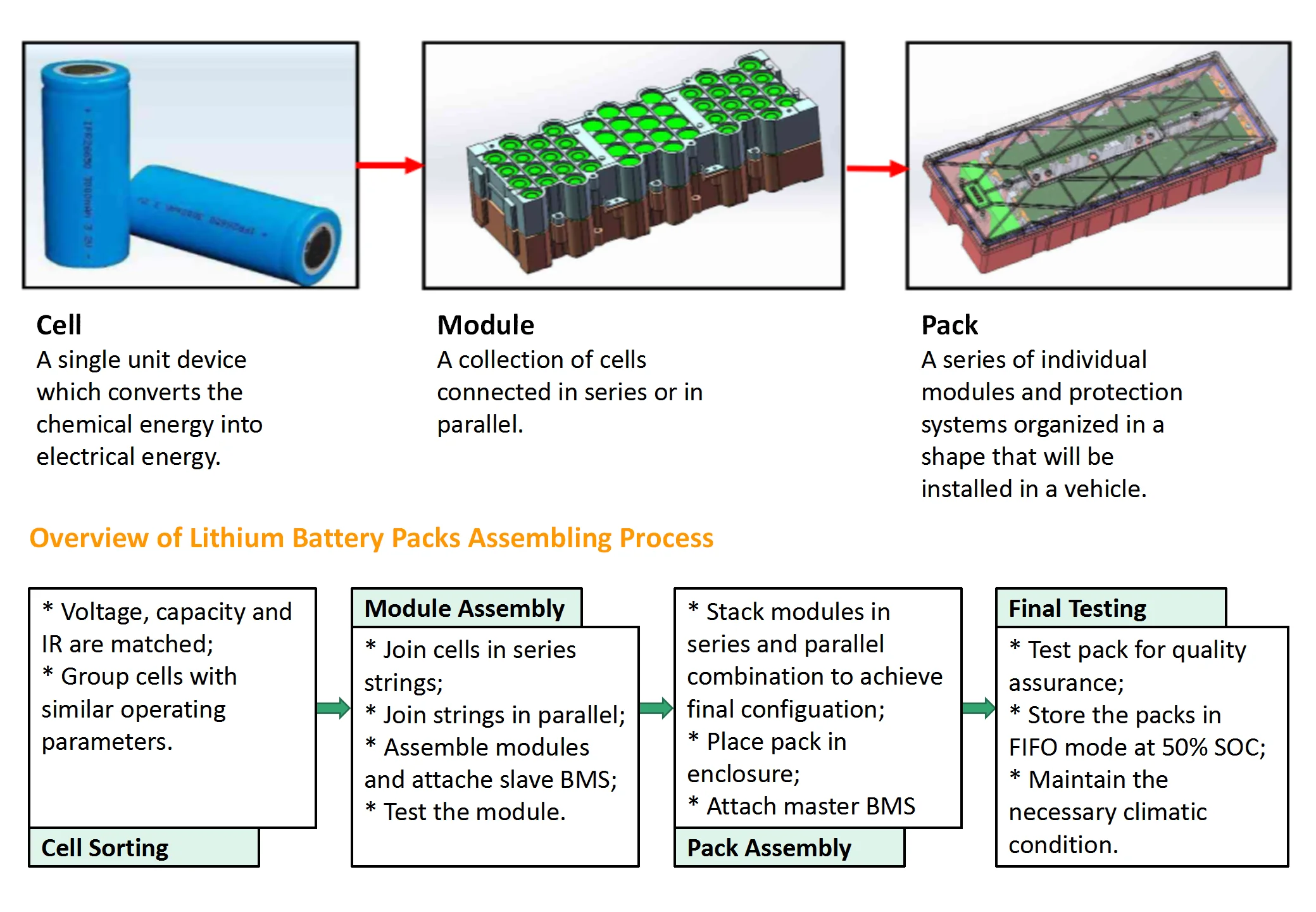

1. What is a lithium-ion battery pack?

A lithium-ion battery pack is an assembly of multiple lithium battery cells configured to work together as a single unit. It can consist of a single battery or a series of parallel battery modules.

2. What are the key components of a battery pack?

A battery pack typically includes the battery cells, bus bar, soft connections, protection board, outer package, output connectors, insulation materials, and a cell holder.

3. What does 'series parallel composition' mean?

Series parallel composition refers to the arrangement of battery cells where some cells are connected in series to increase voltage, while others are connected in parallel to increase capacity.

4. How does the performance of a battery pack compare to a single battery?

The cycle life of a battery pack is generally lower than that of a single battery due to variations in cell performance and the necessity for balancing the cells.

5. What is the importance of consistency in battery packs?

High consistency in battery capacity, internal resistance, voltage, and discharge curves is crucial to ensure the reliable performance and longevity of the battery pack.

6. What are the requirements for selecting battery cells?

Battery cells must be of the same type and model, with differences in capacity, internal resistance, and voltage not exceeding 2% for optimal performance.

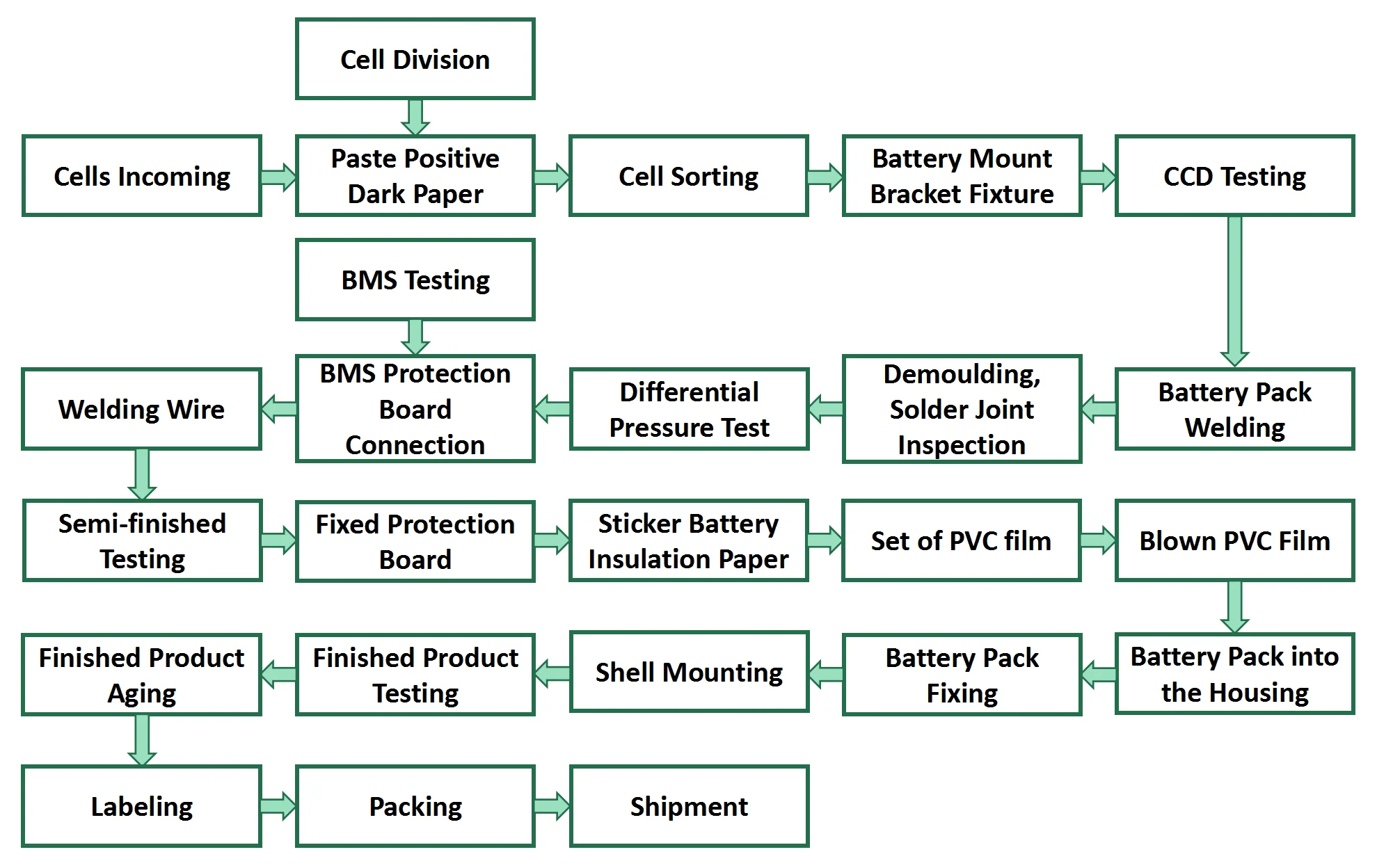

7. Why is battery management system (BMS) testing necessary?

BMS testing is essential to ensure that the battery protection circuit functions correctly and falls within the specified parameters, helping to prevent malfunctions during operation.

8. What is the function of insulating paper in battery assembly?

Insulating paper is used to prevent short circuits by isolating the positive and negative poles of the cells and to protect against aging of the materials.

9. How do you ensure the safety of battery packs during assembly?

Safety during assembly is ensured through various testing steps, including cell grading, CCD testing, and insulating paper application to minimize the risk of short circuits and other failures.

10. What welding techniques are used in battery pack assembly?

Common welding techniques for assembling battery packs include spot welding and laser welding, which connect multiple cells to form a higher capacity battery.

11. What is the aging test for battery packs?

The aging test involves charging and discharging the battery pack multiple times to assess its capacity and ensure that protection systems function as intended.

12. What is the significance of thermal management in battery packs?

Thermal management is crucial to prevent uneven temperature distribution, which can lead to performance degradation and safety issues. Proper heat dissipation helps maintain overall battery performance.

13. Can the equipment be customized for different battery types?

Yes, the assembly line equipment can be customized according to the specific requirements of different battery types and production capacities.

14. What are the economic benefits of using this assembly line equipment?

This assembly line equipment is designed to be cost-effective and efficient, increasing productivity while reducing operational costs in battery pack production.

15. How do you ensure high current discharge performance in battery packs?

To ensure high current discharge performance, the battery cells selected must meet high performance standards, and the assembly process must facilitate effective heat dissipation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading