B21, China Town Mall, Midrand

laser trolley case profesional handheld laser cleaning machine rust removal

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600823344719

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

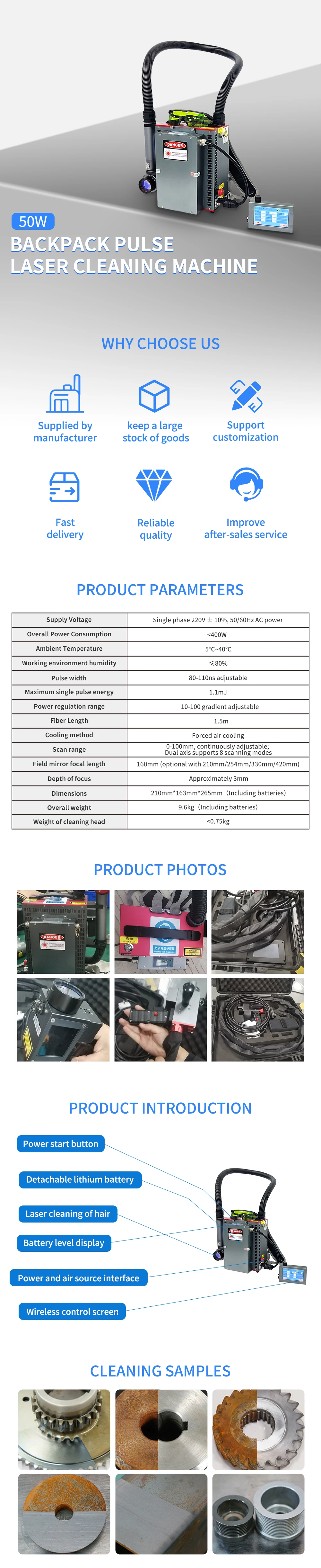

1. What is the 'laser trolley case profesional handheld laser cleaning machine'?

It is a fiber laser cleaning system in a trolley-style case with a handheld laser gun designed for surface cleaning and rust removal on metal parts. Models are available with laser power options of 1000W, 1500W, 2000W and 3000W.

2. Which materials and contaminants can this machine clean?

It is intended for use on metals such as stainless steel, carbon steel and aluminum. Typical applications include removal of rust, paint, oil, scale and other surface contamination from metal substrates.

3. What are the main technical specifications I should know?

Key specs: fiber laser type; laser source brand MAX; laser head brand RAYOUS; available powers 1000W/1500W/2000W/3000W; interface type QBH; dimensions 117 cm × 61 cm × 124 cm; weight around 230 kg.

4. How do I choose the right laser power (1000W–3000W)?

Higher power generally gives faster cleaning speed and greater capability for heavy corrosion or thicker coatings. Choose lower power for delicate surfaces or thin coatings, and higher power for heavy rust, thick paint or high-productivity needs. Consider test trials on representative parts if unsure.

5. Is the machine portable?

The system is mounted in a trolley case and uses a handheld gun for operation, so it is designed to be moved within a workshop. However, the unit weighs about 230 kg, so moving between sites requires suitable handling equipment and at least two people or a pallet jack.

6. What safety precautions must I follow when operating the laser cleaner?

Operate only with trained personnel. Always wear appropriate laser safety eyewear for the laser wavelength, use protective clothing, control access to the work area to prevent bystander exposure, avoid directing the beam at reflective surfaces, and provide local ventilation or fume extraction to remove vapors produced during cleaning. Follow local laser-safety regulations and standard industrial safety practices.

7. What maintenance is required?

Routine tasks include keeping the beam delivery optics and protective windows clean, inspecting the fiber and QBH connector for damage, checking cooling fans/cooling system, verifying grounding and electrical connections, and replacing any worn nozzles or protective glass as needed. Follow the manufacturer's maintenance schedule and procedures.

8. What warranty and documentation are provided?

Core components (including the laser source) have a 1-year warranty. The seller provides a video outgoing-inspection and a machinery test report with the machine.

9. Are spare parts and consumables available?

Critical components are branded (laser source: MAX; laser head: RAYOUS), which helps with sourcing replacements. It is recommended to order spare protective windows/nozzles and to confirm availability of replacement parts with the supplier before purchase.

10. What industries is this machine suitable for?

Common industries include printing shops, manufacturing plants, food & beverage factories, farms, hotels (maintenance), garment shops, construction, machinery repair shops, advertising companies, retail and building material shops—effectively any industry needing metal surface cleaning and rust removal.

11. What kind of connector does the laser use for the delivery fiber?

The system uses a QBH-type fiber connector for the beam delivery interface.

12. Does the machine require any special electrical or installation requirements?

Specific electrical requirements are model-dependent and not listed in the basic spec. Expect a requirement for a stable mains supply sized for the chosen power model, proper grounding, and adequate cooling/ventilation. Request the electrical datasheet from the supplier for installation planning.

13. Is on-site service or a showroom available?

According to the product listing, there is no local service location or showroom provided. Confirm available after-sales support, remote assistance and spare-parts shipping options with the supplier prior to purchase.

14. What quality controls are performed before shipment?

The seller provides a video of outgoing inspection and a machinery test report to document pre-shipment testing and performance verification.

15. How can I get more information, pricing or arrange a demo?

Contact the manufacturer/distributor (brand: Jiangpin; origin: Hubei, China) to request a detailed datasheet, pricing, sample-test services or a demonstration. Ask for performance test results on materials similar to your applications and for details about training or commissioning services.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading