B21, China Town Mall, Midrand

Laboratory HPLC Analysis Instruments for High Performance Liquid Chromatography (HPLC)

- Section : Consumer Electronics

- Category : Test Instruments

- SKU : 1600911086188

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What applications is the Drawell Laboratory HPLC Analysis Instrument suited for?

The system is ideal for pharmaceutical analysis (drug purity and separation), environmental testing (contaminant detection in water, air, soil), food and beverage quality control, and chemical/biochemical research for separating complex mixtures.

2. What temperature range does the instrument support?

The instrument supports a wide temperature range from 7°C to 400°C, enabling compatibility with a broad range of columns and methods.

3. How many program ramps are available and what are they used for?

The system offers 20 program ramps, which allow precise, customizable control over temperature and flow profiles for complex gradient methods and timed sequences.

4. What detection options are available?

Detection options include UV (with a D2 lamp and broad wavelength range), Refractive Index Detector (RID), and Evaporative Light Scattering Detector (ELSD), providing flexibility for many analyte types.

5. What pumping configurations does the instrument offer?

You can choose between an isocratic pump or a binary gradient pumping system, allowing either constant mobile phase composition or controlled mixing of two solvents for gradient separations.

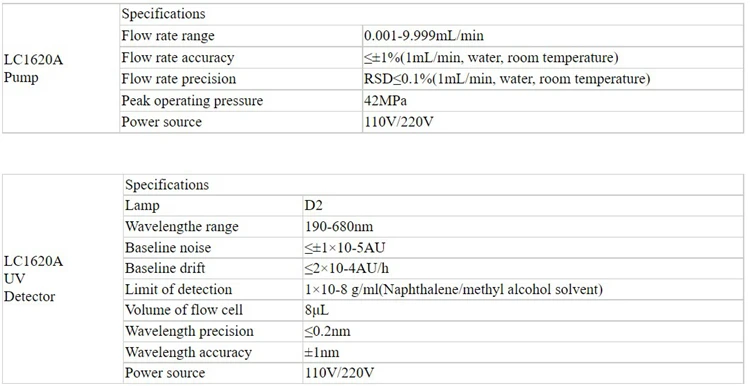

6. What is the instrument's flow rate and maximum operating pressure?

The pump supports flow rates from 0.001 to 9.999 mL/min and a peak operating pressure up to 42 MPa, suitable for both low-flow analytical work and high-pressure separations.

7. How is sample introduction handled?

The system includes a sample injector and an evaporation chamber to streamline sample introduction and improve accuracy; compatibility with manual or autosampler modules depends on the chosen configuration.

8. What user interface does the instrument use?

Operation and real-time monitoring are provided via a 7-inch touch screen display for intuitive control of methods, ramps, and instrument status.

9. What maintenance tasks are typically required?

Routine maintenance includes replacing the D2 lamp as needed, changing solvent and inlet filters, checking seals and tubing for leaks, degassing mobile phases, and periodic pump and detector service as recommended in the manual.

10. What types of mobile phases and consumables should be used?

Use HPLC-grade solvents and appropriate mobile phase additives for your method. Typical consumables include columns, pre-filters, frits, septa, vials, and replacement lamps/parts specified by the manufacturer.

11. How do I ensure safe operation of the HPLC system?

Follow standard laboratory safety: handle solvents in a fume hood, wear appropriate PPE, ensure proper waste collection and disposal, relieve system pressure before maintenance, and follow the instrument manual for electrical and thermal safety.

12. Is the system suitable for method development and validation?

Yes. With programmable ramps, gradient pumping, and multiple detectors, the system supports method development and can be used in method validation workflows; follow institutional and regulatory IQ/OQ/PQ procedures for formal qualification.

13. What environmental or installation requirements should I plan for?

Provide a stable, vibration-free bench or cabinet, adequate ventilation (especially for solvent use), correct electrical supply, and space for waste containers and accessory modules. Refer to the installation manual for exact power and footprint specifications.

14. How do I obtain support, spare parts, or training?

Contact the vendor or authorized distributor for warranty information, after-sales support, spare parts (e.g., D2 lamps, pump seals), and training options. They can provide service plans and scheduled maintenance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading