B21, China Town Mall, Midrand

Interlock Brick Making Machine Including 1 Mould

- Section : Machinery

- Category : Brick Making Machinery

- SKU : 1600908494364

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Interlock Brick Making Machine and what does "including 1 mould" mean?

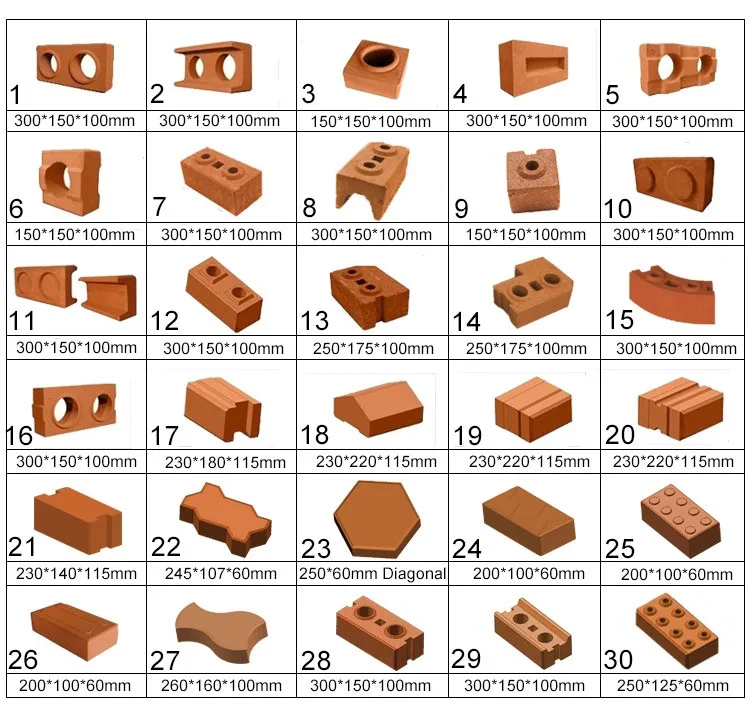

This is a hydraulic interlocking brick making machine that compresses mixes of sand, stone powder, cement, fly ash, gravel and water to produce interlocking ecological slope-protection bricks. "Including 1 mould" means the machine is supplied with one interchangeable mould (die) which defines the brick shape and size. Additional or custom moulds can be ordered separately.

2. What raw materials can I use with this machine?

Common raw materials are river sand, crushed stone/aggregate, stone powder, cement, fly ash and water. The machine can handle various blends used for ecological slope-protection and interlocking bricks; exact mix proportions depend on local materials and desired brick strength.

3. What types of bricks does the machine produce?

It produces chain-type ecological slope protection interlocking bricks and other interlocking/block shapes determined by the mould. Bricks are designed to resist soil and water erosion and interlock to form stable slope surfaces.

4. What is the production capacity of the machine?

Rated capacity is up to 2,000 pieces per day. Actual output depends on shift length, mould size, mix design, curing method and operator efficiency. Example: on an 8-hour shift this equates to roughly 250 pieces/hour (approximate).

5. What are the machine's power and electrical requirements?

The machine uses a 2.2 kW hydraulic power system and is specified for 220 V supply. Verify whether your site provides compatible single-phase or three-phase power and use suitable protective devices; a stable power source and correct earthing are required.

6. How does the hydraulic system work and what are its benefits?

A hydraulic pump drives the compression system to apply consistent pressure to the mould, producing dense, uniform bricks. Benefits include repeatable compaction, low vibration, and reliable production. Regular hydraulic maintenance is required to retain performance.

7. Can I order additional or custom moulds?

Yes. Additional standard moulds and bespoke moulds (different shapes, sizes or cavity counts) can normally be supplied. Provide the required brick dimensions and profile so the supplier can confirm compatibility and pricing.

8. What training or support is provided for operation and commissioning?

Most suppliers offer basic on-site or remote commissioning support and operator training covering machine operation, routine maintenance, safety and mix testing. Confirm the level of training included at purchase.

9. What maintenance is required and how often?

Daily tasks: clean mould and machine surfaces, remove debris, check fasteners and hydraulic pipes. Weekly/monthly: check hydraulic oil level and look for leaks, lubricate moving parts, inspect electrical connections. Replace hydraulic oil and filters per supplier schedule. Keep a log of maintenance actions.

10. What curing requirements do the bricks have?

Curing depends on mix and climate. Generally, keep freshly demoulded bricks moist and shaded for initial days to prevent rapid drying; many projects use wet curing or covered curing for several days and achieve full design strength around 28 days. Follow local engineering recommendations and trial batches to finalize curing.

11. How many operators are needed to run the machine?

A small team is typically sufficient — commonly 1 operator for machine control plus 1–2 helpers for material feeding, demoulding and stacking. Staffing needs vary with automation level, production rate and site layout.

12. What site preparations or foundation does the machine need?

A level, solid surface (preferably a concrete slab) is required. Ensure adequate space for material storage, mould handling, curing area and forklift or manual transport. Provide a suitable 220 V power point, drainage for wash water and shelter from extreme weather if possible.

13. What is included in delivery and how is the machine packaged?

Typical delivery includes the machine, the single mould, basic tooling, an operator manual and packing for export (plywood/crate or wooden frame). Exact inclusions vary by supplier — confirm packing list, spare parts kit and whether on-site installation is included.

14. Are spare parts, after-sales service and warranty available?

Most suppliers provide spare parts, technical support and a warranty—terms vary. Ask the seller for warranty duration, what it covers, lead times for critical spare parts and options for local service agreements.

15. How do I determine the correct raw mix proportions for good bricks?

Mix proportions depend on material properties and target strength. Perform trial mixes and compressive strength tests (e.g., trial cubes/blocks) to optimize cement/fly ash/aggregate ratios, water content and compaction settings. If needed, request technical assistance from the supplier or a materials engineer.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading