B21, China Town Mall, Midrand

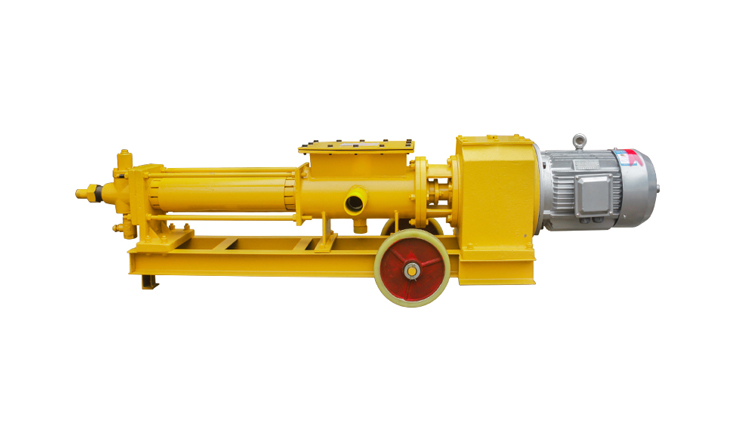

Intelligent Construction Grouting Equipment mortar Machine for Construction Project

- Section : Machinery

- Category : Other Construction Machinery

- SKU : 62459040337

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Intelligent Construction Grouting Equipment Mortar Machine?

The primary function of the Intelligent Construction Grouting Equipment Mortar Machine is to efficiently and precisely mix mortar and perform grouting tasks in construction projects.

2. What are the key features of this mortar machine?

Key features include automatic grouting, high-speed mixing, a vacuum pump with high performance, automatic and manual modes, and real-time data tracking.

3. How does the automatic grouting feature work?

The automatic grouting feature includes automatic feeding, measurement, and high-speed mixing, allowing for seamless integration of slurry and cement into the grouting process.

4. What is the stirring speed of the machine?

The stirring speed of the machine is 1020 revolutions per minute (rev/min).

5. What is the maximum theoretical workload of the mortar machine?

The theoretical workload of the machine ranges from 4.5 to 10 cubic meters per hour.

6. How accurate is the weighing system in the mortar machine?

The weighing accuracy of the machine is ±0.4%, which exceeds the Ministry of Railways' requirement of ±1%.

7. Can the machine operate continuously without interruptions?

Yes, the machine is designed for continuous operation with stable pressure and no fluctuations, ensuring consistent slurry pumping.

8. Is there a manual mode available for this mortar machine?

Yes, the machine features a manual override that allows for individual work procedure completion if automatic operation is not preferred.

9. What is the maximum vacuum capability of the vacuum pump?

The vacuum pump can achieve a maximum vacuum of -0.097, surpassing the Ministry of Railways' standard of -0.092.

10. What materials can the mortar machine mix?

The mortar machine can mix various materials including slurry, cement, and other construction materials as needed.

11. How does the pressure control feature work?

The DYL90-speed grouting pump includes step-less pressure control, allowing for precise adjustments to ensure accurate grouting.

12. What is the pressure gauge range for the machine?

The pressure gauge range is 1.6 MPa, with a minimum scale value of less than 0.1 MPa.

13. How does the water addition process function?

The system automatically adds 90% or 80% of water, followed by the remaining water addition for optimal mixing before discharge.

14. What type of projects is this mortar machine best suited for?

This mortar machine is ideal for large-scale construction projects requiring continuous and stable grouting performance.

15. Does the machine provide historical data tracking?

Yes, the machine records stirring data that can be accessed at any time for historical analysis.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading