B21, China Town Mall, Midrand

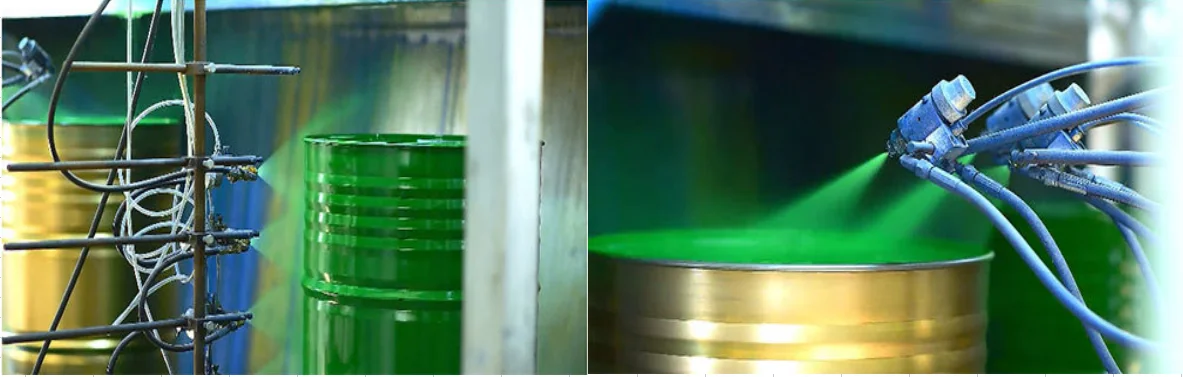

Inside and Outside Spray Painting Room (3-color) for Steel Drum and Steel Drum Making Machine 210L or 55 Galleon

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600532623576

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum size of the steel drum that can be used in this spray painting room?

The spray painting room is designed for steel drums with a capacity of up to 210 liters or 55 gallons.

2. What materials is the spray painting room made of?

The structure is made of carbon steel, while the sink, water curtain, and water vapor separation room are made of SS304 stainless steel.

3. How does the purification method work in this spray painting room?

The purification method combines a water curtain, shower, and water vapor separator to effectively manage solvent volatile gases before they are released into the atmosphere.

4. What is the production capacity of this spray painting room?

The spray painting room has a production capacity of 200 pieces per hour.

5. How many sprayers are included with the spray painting room?

The spray painting room includes three Europe Airless spraying machines and one Ou Naishi spray gun (ZPQ 23).

6. What types of nozzles are used in this spray painting room?

The spray painting room utilizes nozzles from the American Spray System Co., with four nozzles sourced from Nordson products.

7. What is the dimension of the spray painting room?

The dimensions of the spray painting room are 6000 mm x 4320 mm x 4000 mm.

8. How is the spraying controlled in this system?

Spraying and transmission are controlled via a PLC control cabinet, ensuring precise operation.

9. What is the spraying method used in this room?

The spraying method employed is three-color vertical spraying, allowing for efficient and precise application.

10. What type of machines are included for steel drum rotation?

The system includes two sets of fully enclosed steel drum rotating machines with four supporting wheels and one set of a lifting rotating machine.

11. Is this spray painting room suitable for outdoor use?

Yes, it is designed for both inside and outside use, making it versatile for different working environments.

12. What kind of maintenance is required for this spray painting room?

Regular maintenance includes checking the purification system, cleaning the sprayers, and ensuring that the PLC control cabinet is functioning properly.

13. Can this system handle multiple color applications?

Yes, the system is specifically designed for three-color applications, allowing for complex designs on steel drums.

14. What safety features are included in this spray painting room?

Safety features include a water vapor separator to minimize harmful emissions and a fully enclosed design to ensure operator safety.

15. What is the energy consumption of this spray painting room?

Energy consumption varies based on usage, but the PLC system is designed for efficiency to reduce overall energy costs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading