B21, China Town Mall, Midrand

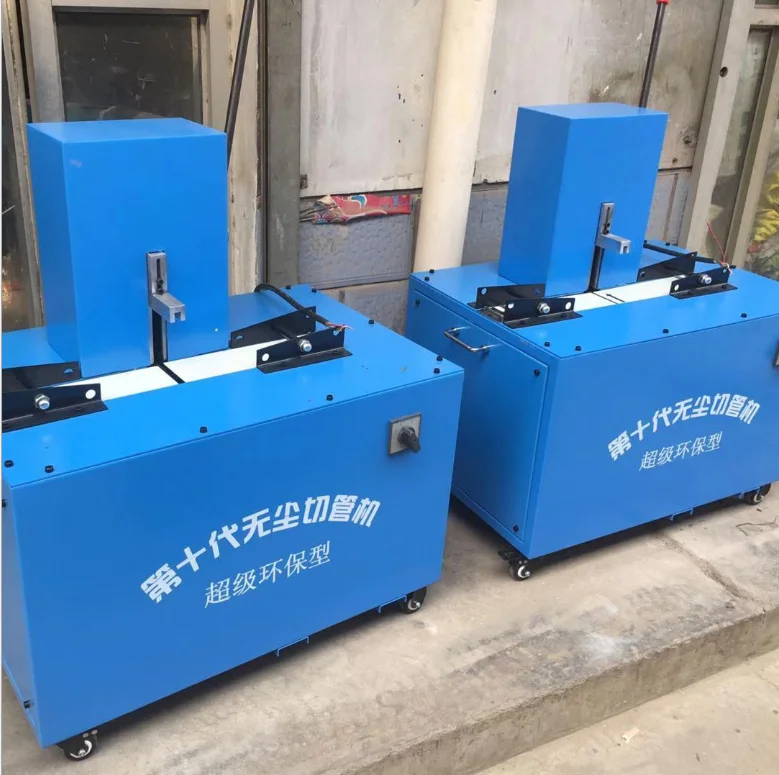

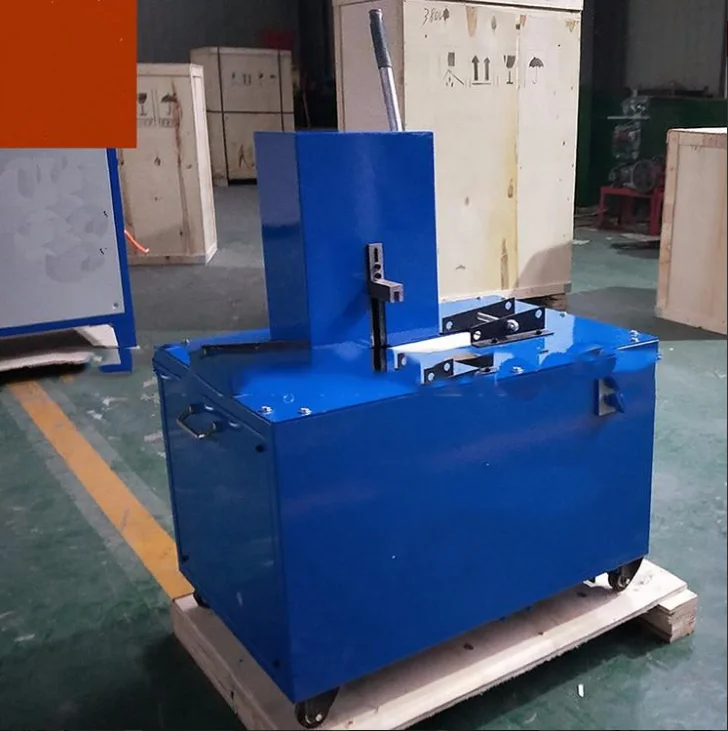

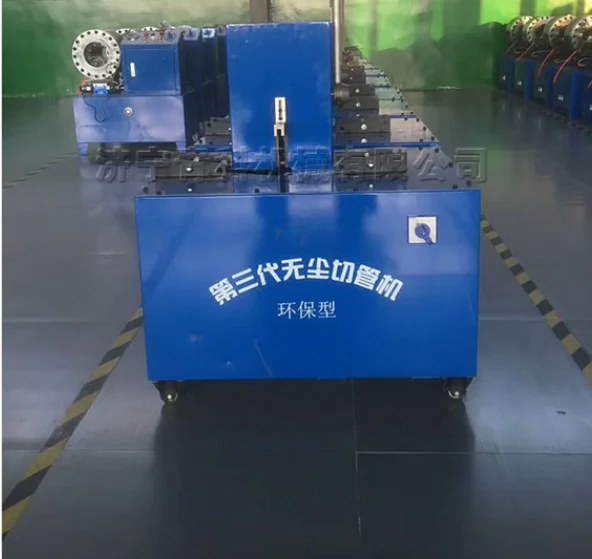

Hose Cutting Machine Model Pin Rubber Extruder

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600325114106

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Hose Cutting Machine Model Pin Rubber Extruder used for?

This machine is used to accurately and efficiently cut a wide range of hoses, streamlining hose production and maintenance tasks in industrial and workshop settings.

2. What hose sizes can this machine handle?

It accommodates a crimping/cutting range of 6–51 mm, making it suitable for many common hose diameters used in hydraulic, pneumatic and general-purpose applications.

3. What power specifications does the machine require?

The machine is driven by a 3 kW motor. Exact voltage and phase (e.g., single- or three-phase) depend on the configuration—confirm the required electrical supply with the supplier at the time of order.

4. Is the machine fully automatic?

Yes — the machine is designed for automatic operation to reduce operator effort and improve throughput, though operators must still load/position hoses and follow safety procedures.

5. What types of hose materials can it cut?

It is suitable for most industrial hose materials such as rubber, PVC, thermoplastic, and many reinforced hose constructions. For very specialized or abrasive materials, please consult the manufacturer.

6. How fast does the machine cut hoses?

Cutting speed varies with hose material, diameter and settings. The machine provides consistent power for efficient cutting; contact the supplier for measured cycle times or request a demonstration with your specific hose type.

7. What safety features should I expect?

Standard safety measures include guarded cutting areas, emergency stop controls and operator interlocks. Operators should always use appropriate PPE and follow the provided safety instructions in the user manual.

8. What are the machine dimensions and what workspace is required?

Overall dimensions are 900 x 600 x 700 mm. Ensure a stable, level surface with adequate clearance around the machine for loading/unloading hoses and maintenance access.

9. How is maintenance handled and how often should I replace blades or wear parts?

Routine maintenance includes keeping cutting surfaces clean, checking and tightening fasteners, lubricating moving parts as recommended, and inspecting blades regularly. Blade/part replacement intervals depend on usage and material; heavy-duty use may require more frequent replacement. Contact the supplier for genuine replacement parts and recommended maintenance schedules.

10. Is there warranty and after-sales support?

Yes — the product includes after-sales and warranty support. Warranty terms (duration and coverage) vary by supplier and region, so confirm the specific warranty and support options when purchasing.

11. Are spare parts and consumables available?

Yes. Replaceable blades, fasteners and other consumables are available — contact the manufacturer or authorized dealer for part numbers, pricing and lead times.

12. Does the machine require special installation or commissioning?

Installation typically requires a suitable power connection and a stable mounting surface. For optimal performance, some buyers request on-site commissioning or setup assistance from the supplier; inquire about installation services when ordering.

13. Can I adjust cut length or cutting parameters?

Yes — cutting parameters and settings are adjustable to accommodate different hose diameters and desired cut quality. Specific controls and adjustments depend on the machine configuration; consult the operator manual for details.

14. Does the model name 'Pin Rubber Extruder' mean it's an extruder rather than a cutter?

Despite the model name, this product is a hose cutting machine. 'Pin Rubber Extruder' appears to be the manufacturer's model or product line name; verify the product specification sheet if you need extruder functionality.

15. How can I get a demonstration or technical specifications before buying?

Contact the manufacturer or authorized dealer to request a datasheet, full technical specifications, sample cuts, or an in-person/virtual demonstration. They can also provide information about power options, certifications and customization if needed.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading