B21, China Town Mall, Midrand

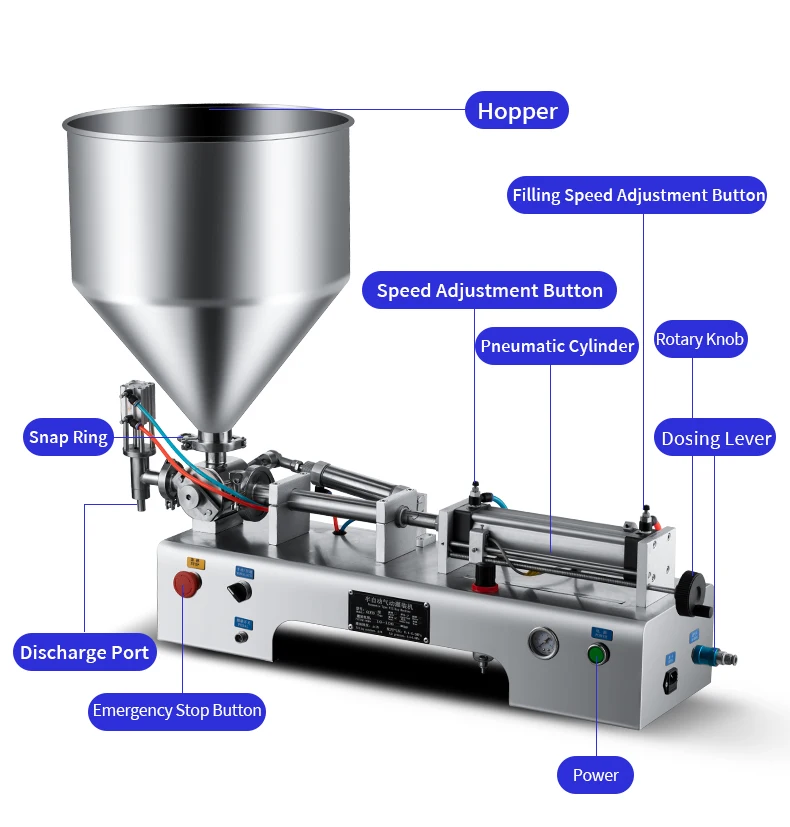

Horizontal Single Head Liquid Automatic Filling and Packaging Machine

- Section : Machinery

- Category : Filling Machines

- SKU : 1600463872799

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Horizontal Single Head Liquid Automatic Filling and Packaging Machine used for?

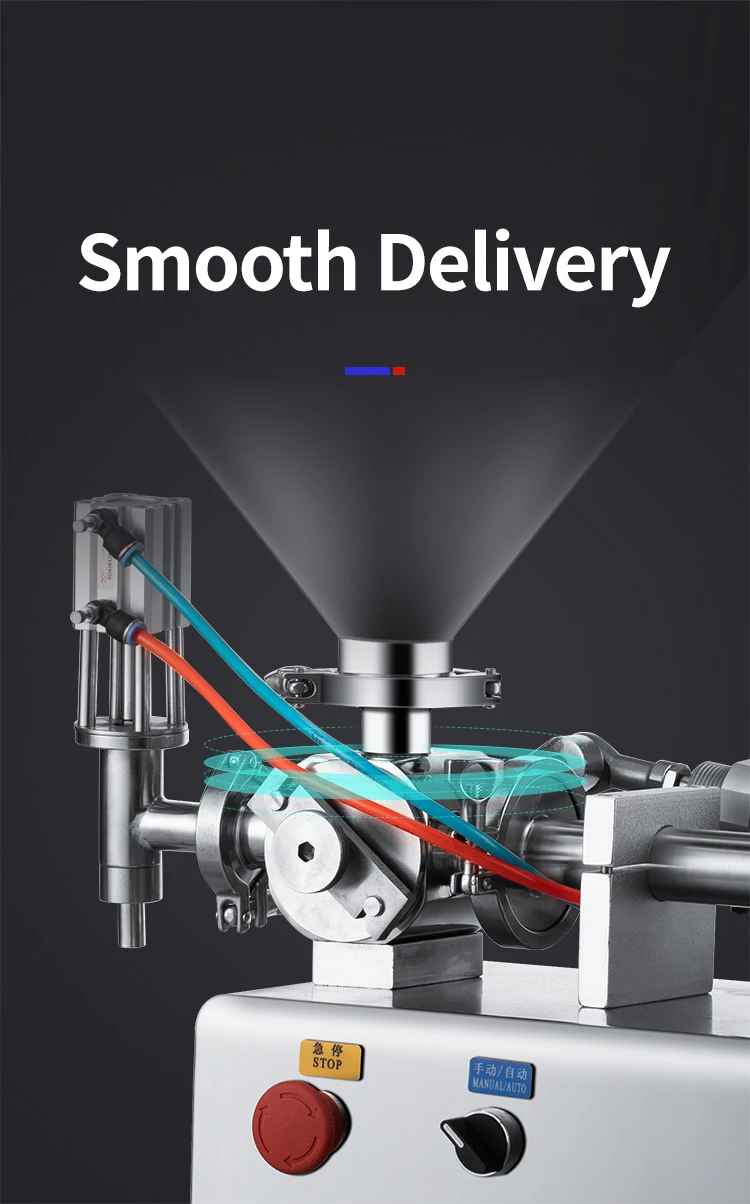

It is used for automated filling and packaging of a wide range of liquid products in industries such as food, beverages, and pharmaceuticals, offering precise, high-speed, single-head filling into heat-sealable pouches or containers.

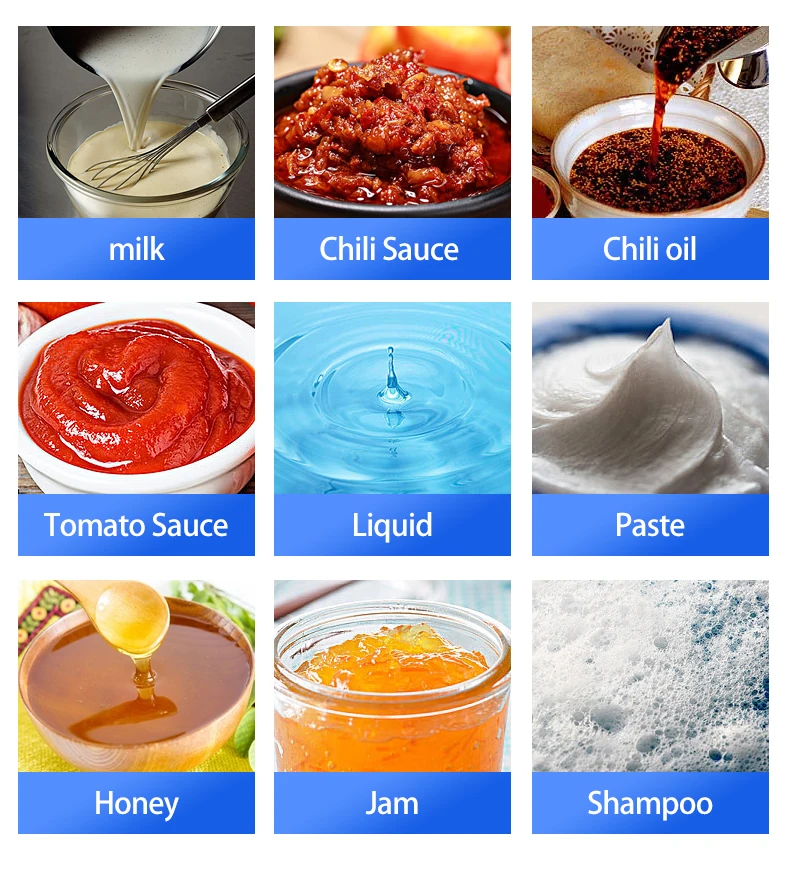

2. Which liquids are compatible with this machine?

The machine handles almost all low-to-medium viscosity liquids without particles (water-like to syrupy). It is not suitable for high-viscosity liquids containing solid particles. For borderline products, consult us with product samples.

3. What packaging materials does the machine support?

It works with heat-sealable composite films including plastic film, laminated film, and aluminum foil suitable for automatic forming, filling, and sealing processes.

4. What are the available models and their filling ranges?

Models include OX-WGD10 through OX-WGD70. Typical weighing/filling ranges are: OX-WGD10: 5–100 ml; OX-WGD20: 10–200 ml; OX-WGD30: 30–500 ml; OX-WGD40: 50–500 ml; OX-WGD50: 100–1000 ml; OX-WGD60: 200–2500 ml; OX-WGD70: 500–5000 ml.

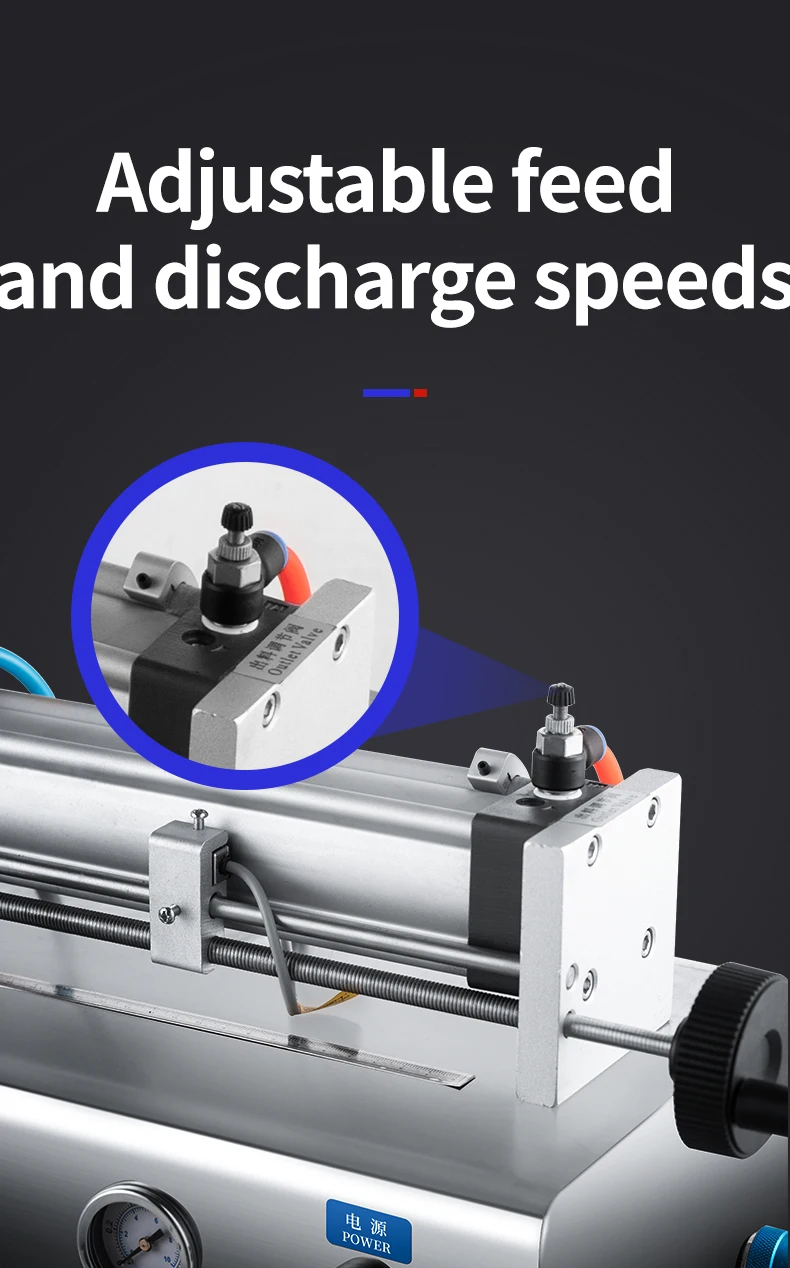

5. What is the filling speed and accuracy?

Packing speed is adjustable up to 1–25 bottles (or pouches) per minute. Filling precision is ≤ ±1% with an approximate error range of about 2 g depending on product and settings.

6. What are the electrical and power requirements?

Standard specification: 220 V / 50 Hz and rated power approximately 50 W. Confirm local voltage/frequency compatibility for your region.

7. What materials is the machine constructed from?

Critical components in contact with product are made from food-grade stainless steel to ensure durability, hygiene, and compliance with food/pharma processing requirements.

8. How easy is the machine to operate and maintain?

The machine features an intelligent control system and a user-friendly interface for easy operation. Routine maintenance is minimal: regular cleaning, periodic inspection of seals/nozzles, and checking pneumatic/electrical connections.

9. How should I clean this machine?

Shut down and disconnect power, drain product lines, then flush and rinse product-contact parts with appropriate cleaning solution or water. Avoid strong corrosive chemicals on stainless surfaces and follow your industry sanitation protocols.

10. Does the machine require calibration and how often?

Yes. Calibrate the filling system during installation and after any significant product change. Frequent checks (daily or per shift) of fill weight are recommended; full recalibration frequency depends on usage and accuracy requirements.

11. What are common troubleshooting steps for inconsistent fills?

Check product viscosity and temperature, verify nozzles and hoses for blockage or air, confirm stable supply pressure and power, inspect sensors and weigh module for contamination, and ensure program settings match the target fill volume.

12. Is installation, training, and after-sales support provided?

Standard packages typically include installation guidance and operator training. After-sales support and spare parts are available—contact the supplier for specific service terms and response times.

13. Can the machine be customized?

Yes. Options such as different nozzle types, dosing systems, pouch/forming attachments, and minor dimensional adaptations can often be provided. Request details with your product specs and production requirements.

14. What safety and quality certifications does the machine have?

Certification details vary by supplier and model. The machine is built with food-grade stainless steel and standard safety features (emergency stop, guards). Ask the supplier for available CE, ISO, or other certification documents.

15. What are the typical operating environment and space requirements?

Operate indoors in a clean, dry, and temperature-stable environment with stable power supply. The machine is compact and lightweight (approx. 25 kg), but exact footprint/dimensions depend on model—request dimensional drawings for planning.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading