B21, China Town Mall, Midrand

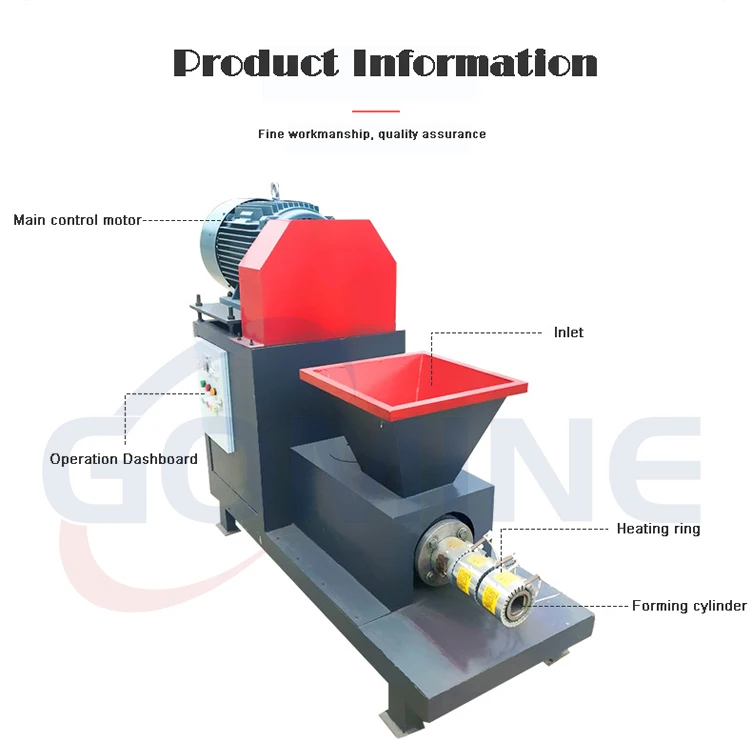

High-Strength Manufacturing Sawdust Charcoal Briquettes Making Machine

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600494536667

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What raw materials can the High-Strength Manufacturing Sawdust Charcoal Briquettes Making Machine process?

The machine can process carbon-containing biomass such as wood chips, sawdust, wood shavings, rice husks, peanut shells, plant straw and similar agricultural/forestry residues. No chemical additives or binders are required.

2. What pretreatment do materials need before briquetting?

Raw materials should be sized (chipped or milled) and dried to an appropriate moisture content. Typical production requires uniform particles and low moisture to ensure good molding and strength — drying, screening and magnetic separation (if needed) are common pretreatment steps.

3. What moisture content is recommended for optimal briquette formation?

Optimal moisture typically falls in a low range suitable for extrusion/pressure molding. Exact values depend on material type and machine model; consult the supplier or run a sample test. In practice users often aim for a relatively low, consistent moisture content to ensure density and structural integrity.

4. What briquette shapes and sizes can the machine produce?

The machine makes rod-shaped briquettes; diameter and length can usually be customized by changing the die and cutter. Common diameters include small to medium sizes used for fuel and charcoal production, but final dimensions depend on the chosen mould and machine configuration.

5. Does the process require additives or binders?

No. The machine uses high pressure and frictional heat to bind the biomass into solid rods without chemical binders. This produces a clean, additive-free solid fuel suitable for many applications.

6. What industries and applications are these briquettes suitable for?

Briquettes made by this equipment are used in industry, agriculture, chemical processing, metallurgy, heating, barbecue/foodservice, and as a raw material for charcoal production or other thermal processes.

7. How is the machine powered and what are typical power requirements?

Power requirements vary by model and capacity. Machines are typically electrically driven (motors for feeders, extruder/press and conveyors). Exact voltage and kilowatt ratings should be obtained from the technical specification sheet for the selected model.

8. What production capacities are available and how do I choose the right model?

Capacities range from small pilot/bench-top units to large industrial production lines. Choose a model based on desired hourly or daily throughput, available space, raw material supply, and end-product size. Contact the supplier with your target capacity for a recommended configuration.

9. What routine maintenance is required?

Regular maintenance includes cleaning the feed and die areas, checking and lubricating bearings and moving parts, inspecting and replacing wear parts (dies, cutters, seals), and monitoring electrical components. Following the manufacturer’s maintenance schedule prolongs machine life and performance.

10. Are spare parts and after-sales support available?

Most manufacturers offer spare parts, wear components and after-sales support including troubleshooting and technical guidance. Confirm lead times for critical spare parts and support arrangements before purchase.

11. Is on-site installation and operator training provided?

Many suppliers provide on-site installation, commissioning and operator training either included or for an additional fee. Check contract terms to confirm what services are included and whether remote support is available.

12. What safety features should I expect and what safety precautions are recommended?

Expect emergency stop buttons, guards on moving parts, electrical protection and interlocks depending on the model. Operators should follow lockout/tagout procedures, wear appropriate PPE, keep feeding systems clear of obstructions and follow the manufacturer’s safety manual.

13. How dense and durable are the produced briquettes?

The machine produces high-strength, high-density rod briquettes suitable for handling, storage and combustion. Exact density and mechanical strength depend on raw material, moisture content and molding parameters; sample testing is recommended to confirm product specifications.

14. Can the machine be integrated into a full charcoal production line?

Yes. The briquette/rod making machine is often used as a key component of a charcoal production line, feeding downstream carbonization or finishing equipment. Suppliers can advise on compatible line layouts and material handling systems.

15. How do I evaluate ROI and operating costs for this equipment?

ROI depends on raw material costs, labor, electricity, production throughput, product sales price and local market demand. To evaluate ROI, calculate total capital and operating costs against expected production volume and revenue; request sample runs and energy consumption data from the supplier for accurate estimates.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading