B21, China Town Mall, Midrand

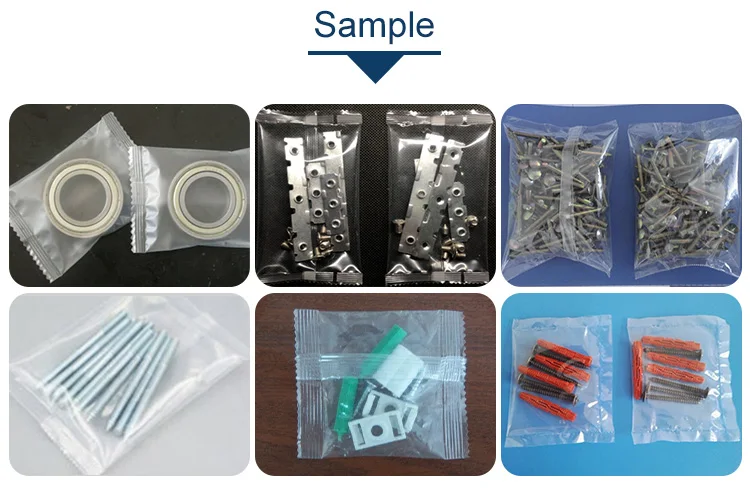

Hardware Counting Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600687862987

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the production speed of the Hardware Counting Packing Machine?

The machine achieves 20–60 bags per minute. Actual speed depends on bag size, product characteristics and operator settings.

2. What bag sizes can the machine handle?

It supports bag lengths from 40 to 200 mm and bag widths from 50 to 150 mm.

3. Which film materials are compatible with this machine?

Compatible roll films include OPP/CPP, OPP/PE, PET/PE and aluminized film. For other specialty films, consult the supplier.

4. How does the machine perform counting and how accurate is it?

The machine uses photoelectric (optical fiber) counting with PLC control and numerical control logic. Counting precision is tested at better than 99.99%. A mechanical counting option is also available.

5. What type of sealing does the machine use?

It uses a heat sealer to securely seal bags and maintain product integrity.

6. What are the electrical and power requirements?

Standard power is 220 V, 50/60 Hz, total rated power 1.2 kW. Confirm local electrical compatibility and earthing requirements before installation.

7. What are the machine dimensions and weight?

Machine footprint is 1200 mm (L) x 680 mm (W) x 1650 mm (H) and it weighs approximately 350 kg.

8. Is the machine fully automatic and how is it controlled?

Yes. It is automatic and controlled by a PLC with a touch screen HMI. Parameters (except mechanical adjustments) can be set and adjusted on the HMI.

9. What happens when the hopper runs empty?

The machine will sound an alarm and/or stop automatically to prevent miscounts or incomplete packs.

10. What routine maintenance is required?

Regular tasks include cleaning film paths and sensors, inspecting and replacing worn sealing jaws and belts, lubricating moving parts per the manual, and keeping the PLC/HMI and electrical components dry and dust-free.

11. Which parts are commonly replaced and are spare parts available?

Common wear parts include sealing jaws, Teflon covers, belts, sensors and solenoid valves. Spare parts availability varies by supplier—contact the manufacturer or distributor for recommended spares and lead times.

12. Can this machine be integrated with upstream or downstream equipment?

Yes, it can typically be integrated with feeders, vibratory hoppers, conveyors, labelers or checkweighers. Integration details and communications interfaces should be discussed with the supplier to ensure compatibility.

13. Is the machine suitable for food and beverage applications?

The machine is used across food, beverage, textile and hardware industries. For food or pharmaceutical use, confirm that contact surfaces, materials and certifications (e.g., food-grade finishes or sanitary options) meet your regulatory requirements.

14. What safety features are included?

Standard safety features include emergency stop, protective guards and PLC alarms. Ensure proper grounding, lockout/tagout procedures and operator training are followed. Additional safety options may be available.

15. What should I do if the machine miscounts or stops unexpectedly?

Check for low hopper level (alarm), inspect and clean photoelectric sensors, verify film alignment and tension, check HMI/PLC fault messages, ensure power supply is stable, and examine mechanical feed components. If the issue persists, contact technical support with the machine serial number and error code.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading