B21, China Town Mall, Midrand

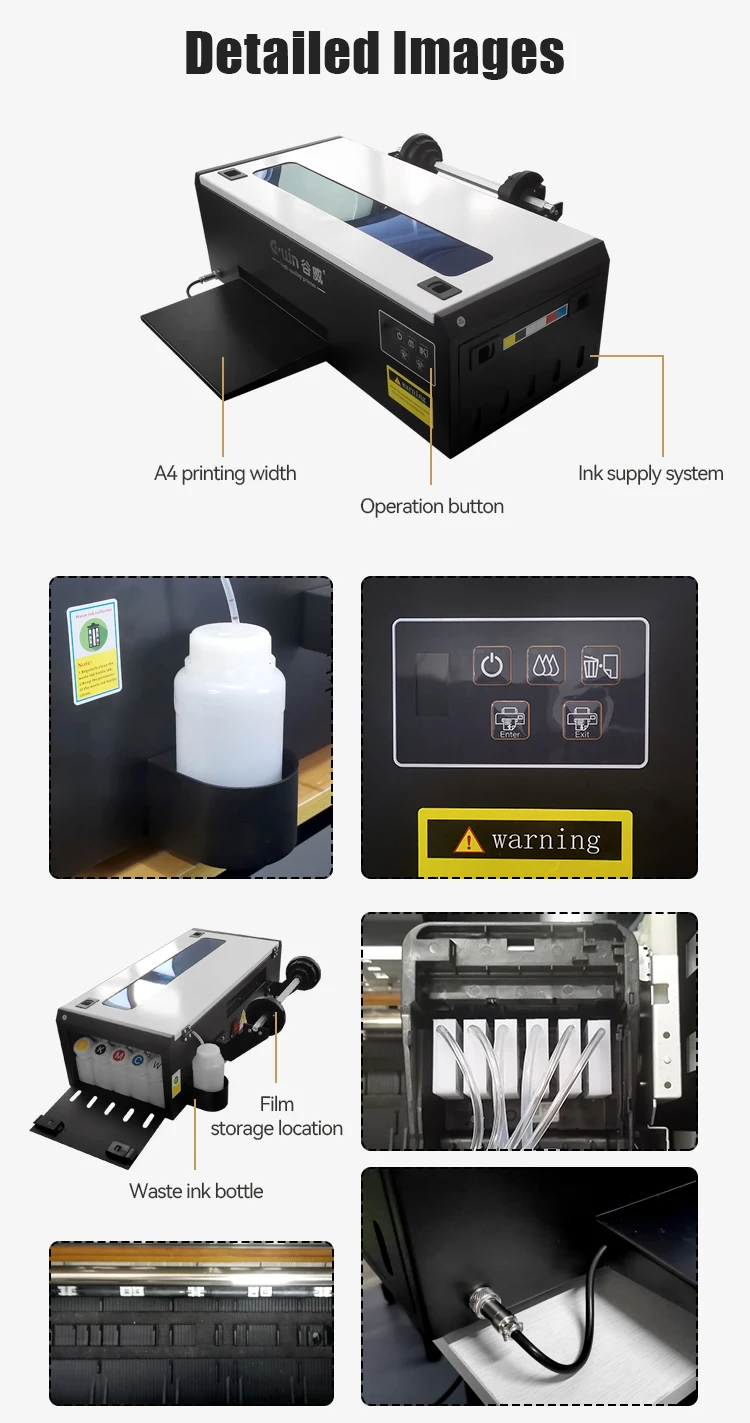

G200 A4 DTF Printer Machine

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600949313184

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the G200 A4 DTF Printer Machine?

The G200 A4 DTF Printer Machine is a desktop direct-to-film (DTF) printer that prints A4-sized designs onto PET film using an 805 printhead and textile pigment inks (CMYK + White).

2. What printing size does this printer support?

The printer supports A4 printing size (approximately 20 x 29 cm as specified) — suitable for A4 transfers and similarly sized designs.

3. What print speed can I expect?

The listed speed is about one A4 print per ~3 minutes (20 x 29 cm in roughly 3 minutes). Actual speed varies with image coverage, RIP settings and print mode.

4. Which printhead does the G200 use?

The G200 uses an 805-series printhead (listed as '805'), which is optimized for textile pigment inks used in DTF printing.

5. What type of ink does the G200 use?

It uses textile pigment ink in CMYK + White configuration, specifically formulated for DTF transfers and textile adhesion.

6. What media does the printer require?

This model prints onto PET film (DTF transfer film). After printing you apply hot-melt powder, cure/dry it, then transfer to the garment.

7. What voltage does the printer support?

The G200 supports both 110V and 220V power input options — confirm which version you are purchasing for your region.

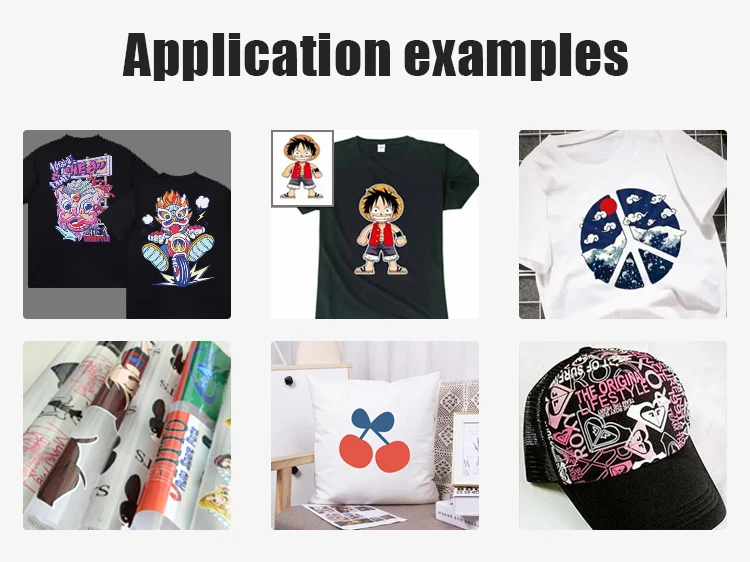

8. What fabrics and substrates are compatible with DTF transfers?

DTF transfers produced by this printer can be applied to cotton, polyester, cotton/poly blends, leather, and other textile substrates once properly heat-pressed and cured.

9. How do I complete a DTF transfer after printing?

Workflow: print on PET film → apply hot-melt adhesive powder → shake off excess → dry/cure powder (oven or dryer) → heat-press transfer to garment → peel film (hot or cold peel per your process). Follow recommended temps and times for best results.

10. Is white ink supported and how is it handled?

Yes — the G200 prints with white ink for opaque prints on dark garments. White ink typically requires regular circulation/cleaning to prevent settling and clogging; follow the maintenance schedule.

11. What maintenance is required?

Regular tasks include printhead cleaning cycles, flushing lines (especially for white ink), topping up/ replacing inks, cleaning capping stations and filters, and routine checks of the media path and heaters. Follow the manufacturer maintenance guide.

12. What kind of print quality (resolution) can I expect?

Print quality depends on the printhead, ink, RIP/software and settings. The 805 printhead with proper RIP settings can deliver high-detail DTF prints suitable for garments and detailed graphics.

13. What consumables and spare parts should I expect to buy?

Common consumables include pigment inks (CMYK+White), PET transfer film, hot-melt powder, replacement printheads/nozzles, cleaning solution, and maintenance parts like wipers and filters.

14. Does the printer come with software or RIP support?

RIP/software support varies by supplier. Most DTF setups require RIP software to manage white channels, ink limiting and halftone settings — check with the seller for included software or recommended RIP packages.

15. Is the print washable and durable on garments?

When printed, powder-coated, properly cured and heat-pressed following recommended parameters, DTF transfers are durable and wash-resistant. Durability depends on curing, press parameters and fabric type.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading