B21, China Town Mall, Midrand

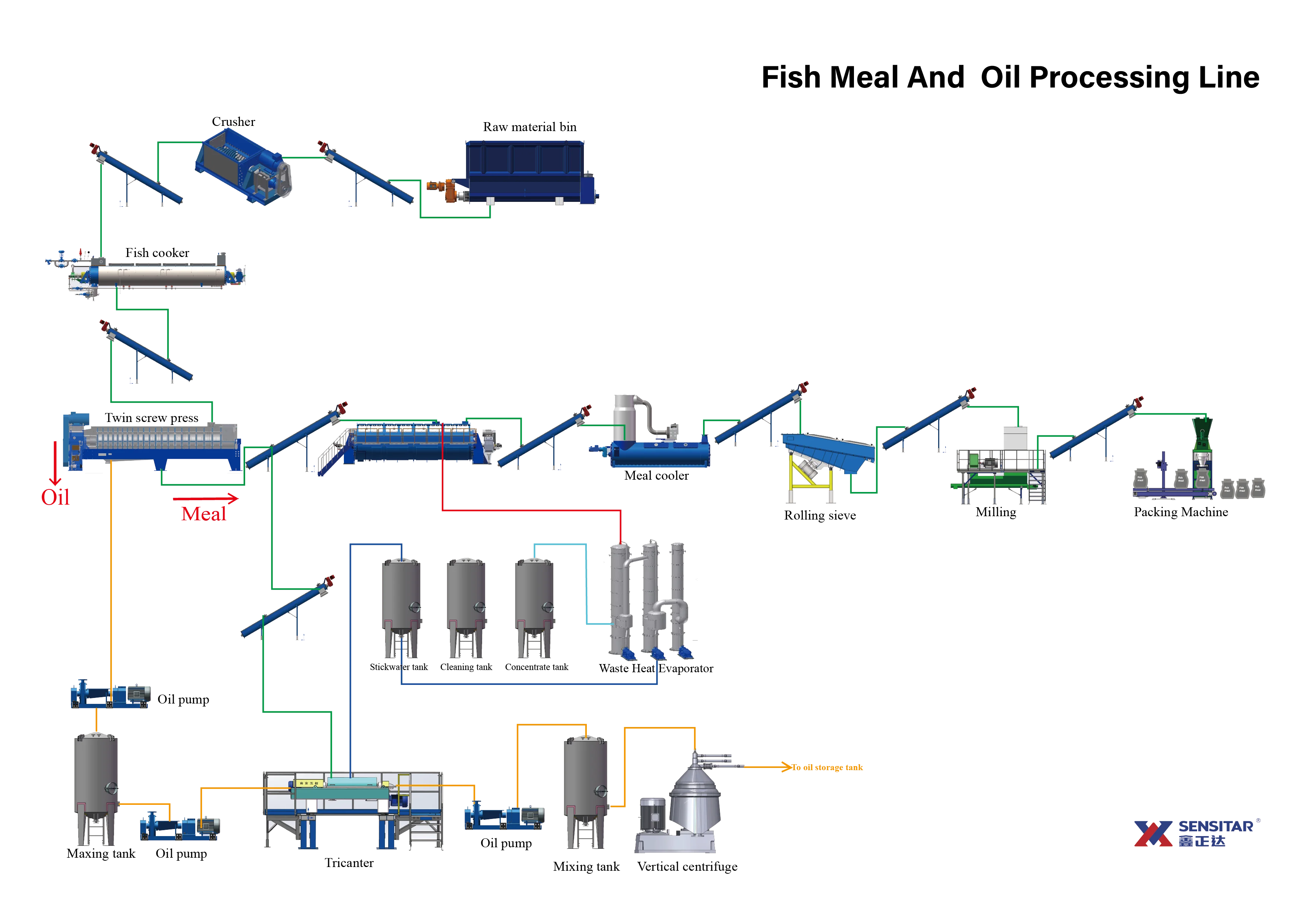

Full automatic small scale fish meal making machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600996006240

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the full automatic small scale fish meal making machine?

The machine processes raw fish, fish steaks, and waste to produce high-quality fish meal and oil through a series of steps including cooking, pressing, drying, and cooling.

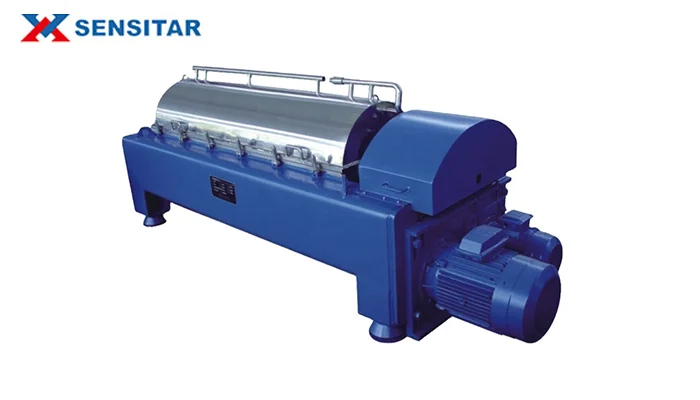

2. What components are included in the fish meal processing line?

The processing line includes a cooker, press, dryer, cooler, and hammer mill, designed for efficient operation and low energy consumption.

3. How does the cooking process work in the fish meal machine?

The cooker uses high temperatures to cook the fish, ensuring a high yield from raw materials of varying quality and composition.

4. What types of fish can be processed with this machine?

The machine can process whole fish, fish heads, fish sausages, offals, fish waste, and other aquatic products like shrimp and loach.

5. What is the moisture content of the final fish meal product?

The moisture content of the final product is less than 12%, ensuring a high-quality skimmed fish meal.

6. What are the advantages of using this fish meal making machine?

Advantages include easy operation, low energy consumption, low maintenance, a long work life, and the ability to produce high-quality fish meal and oil.

7. Can the capacity of the machine be adjusted?

Yes, the motor size and breaker shaft speed can be adjusted to meet the required capacity, allowing for flexibility based on fish type and quality.

8. What is the space requirement for this machine?

The machine is designed to occupy a small workshop area while maintaining a large processing capacity.

9. Is the machine easy to maintain?

Yes, the machine is designed for easy management and maintenance, which helps reduce operational costs.

10. What is the expected lifespan of the machine?

The machine is built for long work life, but the actual lifespan can vary based on usage and maintenance practices.

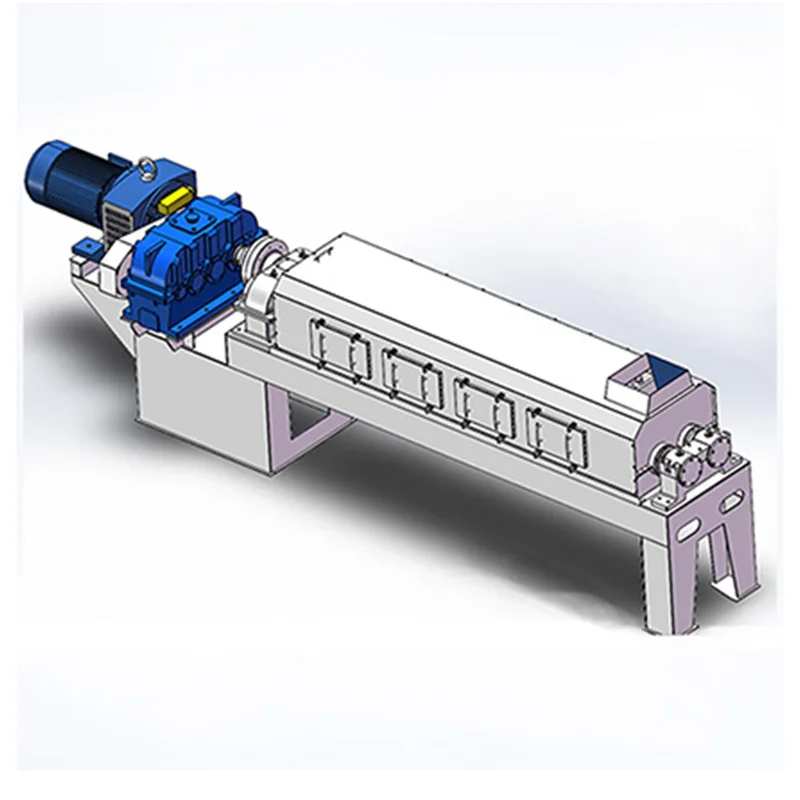

11. How does the pressing process work?

After cooking, the material is pressed to separate the meal cake and oil, resulting in low residual oil in the press cake and high-quality oil.

12. What kind of power consumption should I expect?

The machine is designed for low power consumption, making it cost-effective to operate.

13. What are the dimensions of the cooker?

The dimensions vary by cooker type; for example, the XFC0605 model has a length of 3500 mm, height of 1200 mm, and width of 1000 mm.

14. What is the end product of this machine?

The end product is skimmed fish meal, which can be used in various applications, including animal feed and nutritional supplements.

15. Does the machine require specialized training to operate?

While the machine is designed for easy operation, some basic training may be beneficial to ensure optimal use and safety.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading