B21, China Town Mall, Midrand

Filter Housing Solution for Breweries

- Section : Machinery

- Category : Food & Beverage Machinery

- SKU : 1600867766318

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

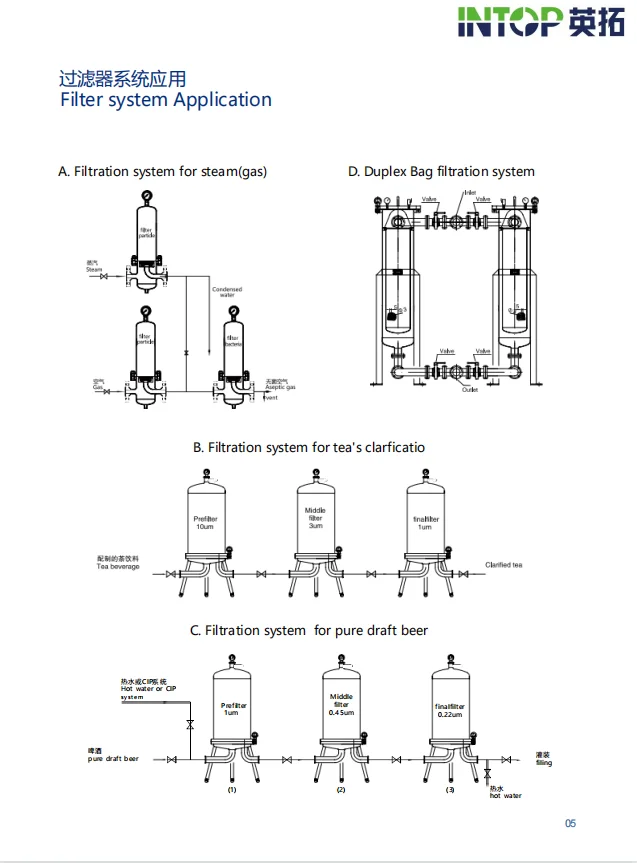

1. What is the Filter Housing Solution for Breweries?

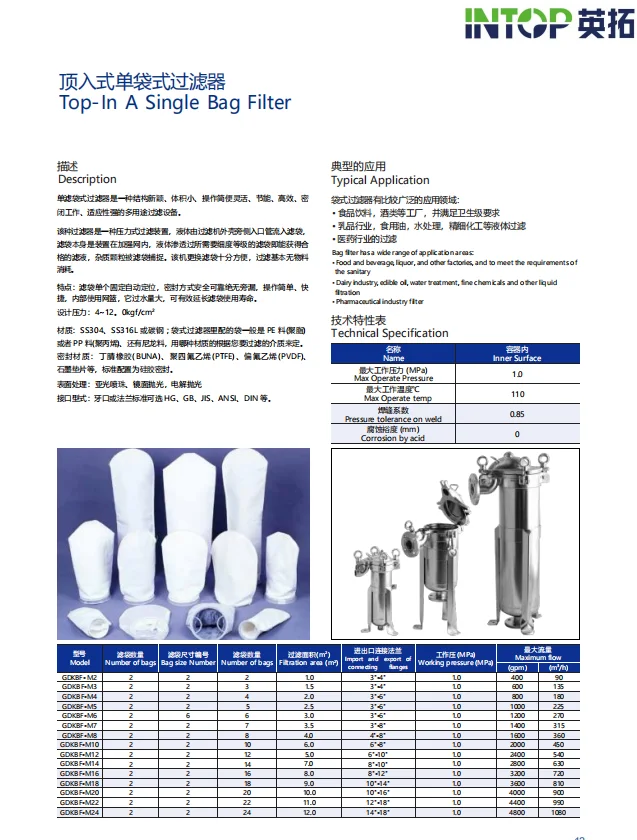

A customized filter housing designed specifically for beer breweries and other food/beverage operations. It houses replaceable filter bags, offers selectable power options (0.55 kW to 55 kW), and is built from SS304/316 stainless steel for corrosion resistance and durability.

2. What power options are available and how do I choose one?

Power options range from 0.55 kW up to 55 kW to suit different throughput and process needs. Choose based on your desired flow rate, system pressure and operating duty. For exact sizing, provide your process parameters (flow, viscosity, inlet/outlet pressures) to our support/sales team for recommendation.

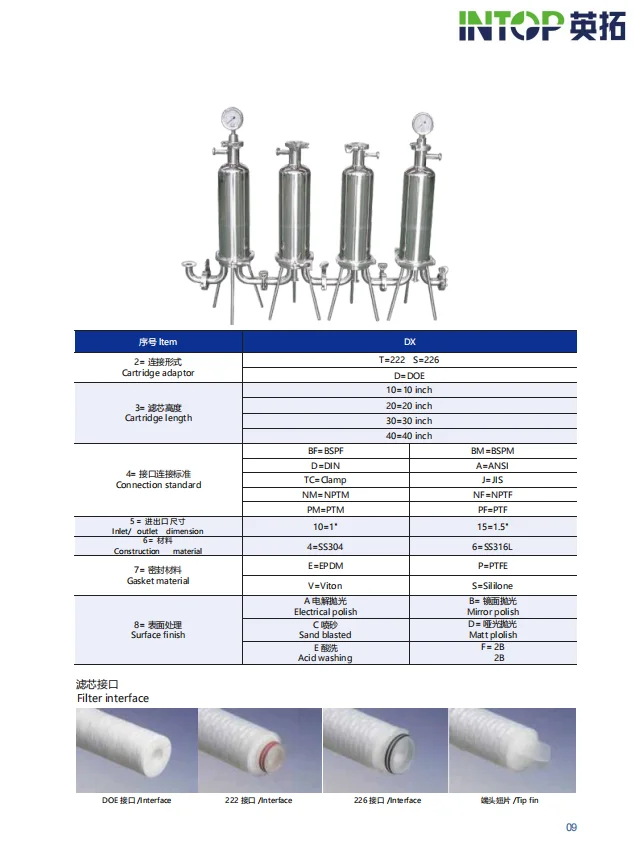

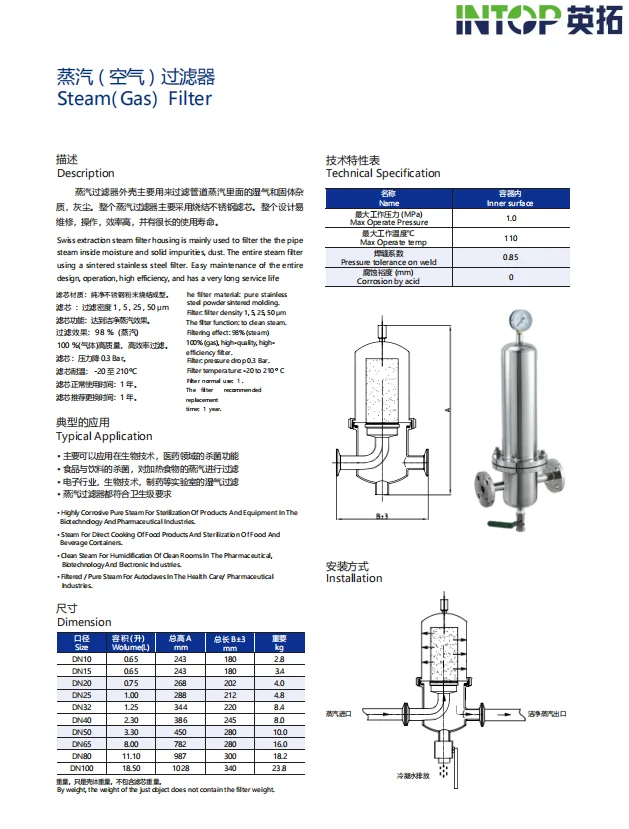

3. What materials are used in construction?

The housing and wetted components are made from high-quality SS304 or SS316 stainless steel, offering excellent corrosion resistance suitable for beverage and medical environments.

4. What filtration precision can I expect?

Filter precision can reach 0.5 µm, allowing fine particulate removal appropriate for many beer clarification and polishing applications.

5. Are the filter bags replaceable and reusable?

Yes. Filter bags are easy to replace—saving labor—and can be cleaned and reused multiple times to reduce operating costs. The housing is designed for quick bag changeouts.

6. What applications and industries is this product suitable for?

Designed for breweries, it is also suitable for hotels, food & beverage factories, farms, restaurants, food shops and even certain medical applications where sanitary filtration is required.

7. What testing and quality assurance do units receive before shipment?

Each unit undergoes comprehensive testing and is shipped with a machinery test report and a video of the outgoing inspection to verify performance and build quality.

8. What warranty and support are provided?

The product comes with a 1-year warranty. A dedicated support team is available to assist with selection, installation guidance, troubleshooting and spare parts.

9. How is the product installed and are there different installation models?

The filter housing supports various installation models to fit different layouts and plant configurations. Our team can recommend the best installation approach for your site and provide installation guidance.

10. How does the unit perform in terms of pressure, leakage and energy use?

The design supports high working pressure with low pressure loss, minimizing energy consumption. It also has a low leakage risk to maintain product quality and operational safety.

11. Is this unit designed for sanitary/food-grade use?

Yes. Constructed from food-grade SS304/316 stainless steel and intended for beverage and food applications. If you require specific certifications or test documentation, please request these from our sales team.

12. What maintenance is required and how often should filter bags be cleaned or replaced?

Maintenance frequency depends on throughput, solids load and product characteristics. Inspect bags regularly and clean them when flow or pressure drop indicates fouling. Replace bags when damaged or cleaning no longer restores performance. Our support team can recommend a cleaning and replacement schedule based on your operating data.

13. Are spare parts and replacement filter bags available?

Yes. Replacement filter bags and common spare parts are available. Contact sales to order spares or to set up a spare parts package matched to your configuration.

14. Can the system be customized for non-standard requirements?

Yes. The solution is customizable in power, materials (SS304 or SS316), and installation model. For special requirements—different ports, instrumentation or documentation—please contact our sales team to discuss options and lead times.

15. What is the typical lead time and delivery process?

Lead time varies with configuration and order size. Each unit is fully tested with a machinery test report and video before shipment. For an accurate delivery estimate, provide your desired specifications to sales and they will confirm current lead times and shipping details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading