B21, China Town Mall, Midrand

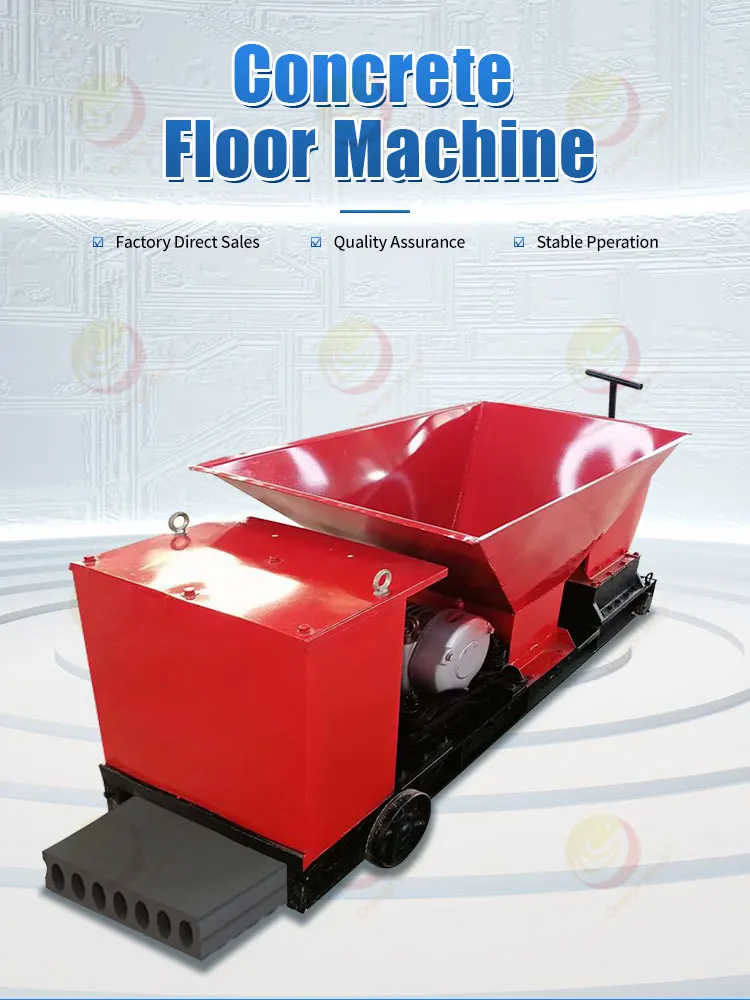

Extruder Prefabricated Structural Hollow Core Slab Making Machine

- Section : Machinery

- Category : Other Construction Machinery

- SKU : 1600699925336-1712320593

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Extruder Prefabricated Structural Hollow Core Slab Making Machine?

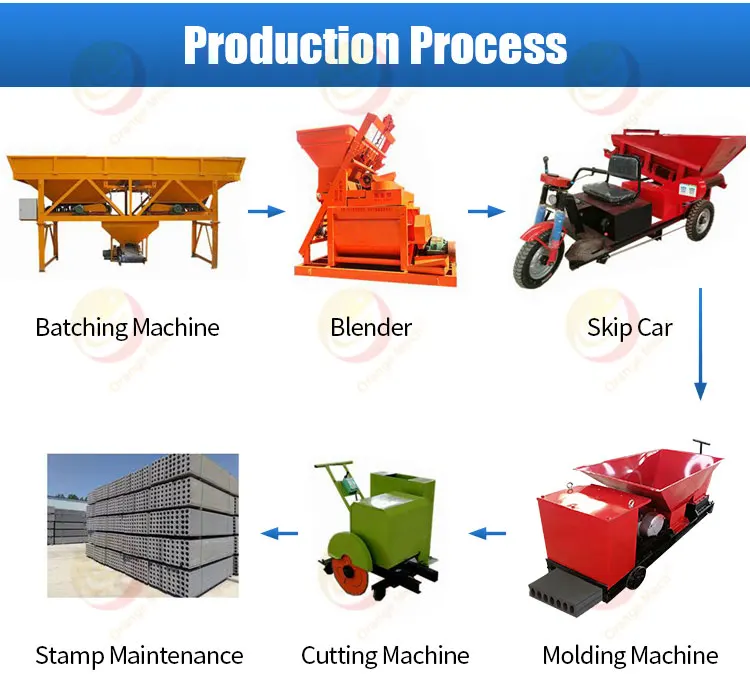

It is an extrusion-type production machine for manufacturing prefabricated hollow core concrete slabs. It produces prestressed, high-bearing-capacity hollow core boards with round holes, suitable for floor and roof panels with options for finished or exposed surfaces.

2. What models are available and how do they differ?

Two models are listed: OR-120-600 and OR-120-500. They share overall dimensions and forming speed but differ in total power (OR-120-600: 8.5 kW; OR-120-500: 7 kW), maximum load capacity (OR-120-600: 8.86 kN/m²; OR-120-500: 10.24 kN/m²) and the number of round holes (OR-120-600: 5 holes; OR-120-500: 4 holes).

3. What are the machine's external dimensions and weight?

Both models have external dimensions of 2100 × 800 × 800 mm and a nominal weight of about 1100 kg.

4. What power supply / total power does the machine require?

Total electrical power consumption is 8.5 kW for the OR-120-600 and 7 kW for the OR-120-500. Confirm site electrical supply requirements with the supplier prior to installation.

5. What is the forming speed and how much board can it produce per hour?

Forming speed is 1.3–1.5 m/min. That equates to approximately 78–90 linear meters of slab produced per hour at continuous operation (actual output depends on board width, thickness, curing/demolding cycle and workflow).

6. What is the maximum board length the machine can make?

The machine supports board lengths up to 6 meters.

7. What are the hole configurations and load capacities?

OR-120-600: 5 round holes, maximum load capacity 8.86 kN/m². OR-120-500: 4 round holes, maximum load capacity 10.24 kN/m².

8. What reinforcement and prestressing system does the machine use?

The design uses a single reinforced member; the stressed bar is a rigid stranded wire (prestressing tendon) providing high strength and toughness. Exact prestressing layouts and strand specifications should be confirmed with your supplier/specification sheet.

9. What surface finishes can be produced?

The extruded hollow slab can be produced without a separate surface layer, or with applied decorative/finish systems such as simulated brick, dry-stuck stone, or other surface treatments during production per customer requirements.

10. What are the primary advantages of this machine?

Key benefits include energy-saving extrusion propulsion, low labor intensity, high production efficiency, strong structural performance (high bearing capacity, large span capability, good seismic behavior), flame retardancy, thermal and sound insulation, and the ability to produce finished surfaces to reduce downstream work.

11. What raw materials are required to operate the machine?

Typical inputs are a suitable concrete mix (ready-mix or site-mixed with appropriate workability for extrusion), prestressing strands/wire, forming accessories and any surface finishing materials. Mix design and admixtures should be chosen to match extrusion and curing requirements.

12. What are the site and installation requirements?

You will need a level, stable foundation area large enough to accommodate the machine and 6 m slab runs, appropriate electrical supply (confirm with supplier), lifting equipment for installation, space for material handling and curing, and access for maintenance. Detailed site preparation instructions are provided by the manufacturer.

13. What maintenance and routine checks are recommended?

Perform daily inspections and cleaning, lubrication of moving parts, check hydraulic/electrical systems, inspect wear parts (molds, cutters, screw/auger), and tighten fasteners as needed. Follow the manufacturer's maintenance schedule for periodic servicing and replacement of consumables.

14. What safety features and operator training are required?

Use appropriate PPE (gloves, eye protection, hearing protection), ensure emergency stop and guarding are functional, and restrict access to moving parts. Operators should receive manufacturer-provided training covering safe operation, routine maintenance, and emergency procedures.

15. Is customization available and what after-sales support is offered?

Customization (different hole patterns, board widths, power options, and finishing capabilities) is commonly available—contact the supplier for options. After-sales support typically includes technical consultation, spare parts supply, operator training, and installation assistance; warranty terms vary by seller and should be confirmed before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading