B21, China Town Mall, Midrand

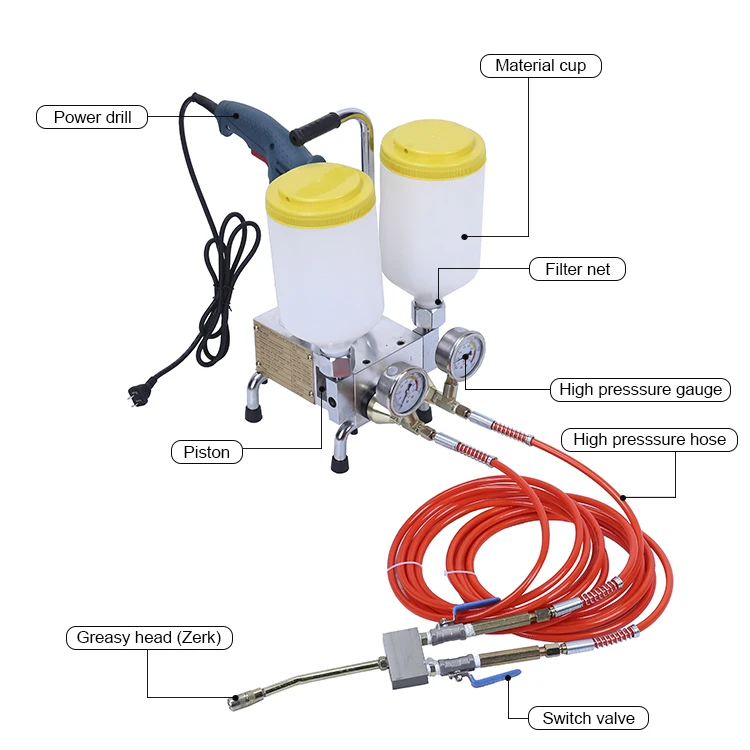

Equipment Small Efficiency High-pressure Cement Grouting Pumping Machine

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1601058878090

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Equipment Small Efficiency High-pressure Cement Grouting Pumping Machine?

It is a portable double-liquid high-pressure grouting machine (model JBY618) designed for structure reinforcement and leak stoppage. It pumps two-component grout for professional water-sealing and injection applications while being easy to maintain and carry.

2. What does "double-liquid" grouting mean?

Double-liquid grouting means the machine mixes and injects two liquid components at high pressure to form grout in situ. This method is commonly used for rapid set and effective sealing/reinforcement of cracks and voids.

3. What are the key technical specifications?

Net weight: 13 kg; Maximum output pressure: 11,000 psi; Power: 690 W / 220 V; Flow rate: 0–0.8 L/min; Hose length: 5 m. It can quickly reach work pressures up to 6,000 psi.

4. Which operating and safe pressure ranges should I know?

Maximum output pressure is 11,000 psi. The unit reaches work pressure up to 6,000 psi quickly. The product listing shows safe ranges for some components (high-pressure pipe ≤ 1,400 psi; nozzle ≤ 16,000 psi; switch valve ≤ 18,000 psi). Always follow the manufacturer manual and safety guidelines when setting pressures.

5. What accessories are included with the machine?

Included: 690 W drill (1 set), two high-pressure hoses (2 × 5 m), shut-off valve (1), repairing kit (1), seal set (1), T-type wrench (1), rubber pads (10), grease coupler (1), filter (1), material cups (2 sets). Machine packers are not included.

6. Are packers included, and how do I choose them?

Packers are disposable and not included. Choose packer size based on the depth and width of the crack or injection point—deeper cracks require longer packers. Contact your supplier for recommended sizes and types.

7. Is the machine portable and suitable for confined spaces?

Yes. At 13 kg and compact design, the machine is portable and intended for on-site work, including confined areas where heavy machinery would be impractical.

8. What electrical supply does the machine require?

The unit requires a single-phase 220 V supply and consumes 690 W. Verify local power availability and use appropriate extension cables rated for the load.

9. How fast can the machine ramp up to working pressure?

The machine is designed for fast construction and can upgrade to a 0–6,000 psi working pressure in a few seconds, which is faster than many comparable models.

10. What routine maintenance is recommended?

After each use, flush and clean hoses and material cups, inspect and replace worn seals (seal set provided), check the filter, lubricate fittings with the grease coupler as needed, and store dry. Use the repairing kit for minor on-site repairs. Follow the operator manual for detailed maintenance intervals.

11. What should I do if I experience low flow or clogging?

Check and clean the filter and material cups, inspect hoses and nozzles for blockages, verify seals are intact, and consult the repairing kit if parts are worn. Ensure correct grout mix and particle size to avoid clogs. If problems persist, contact technical support.

12. What safety precautions should operators follow?

Wear appropriate PPE (gloves, eye protection, respirator if needed), secure packers properly, never exceed recommended pressures for components, inspect hoses for damage before use, and follow lockout/tagout and manufacturer instructions. High-pressure injections can be hazardous—do not point nozzles at people.

13. Can the machine handle different grout materials?

The machine is built for two-component liquid grouting systems. Compatibility depends on the grout chemistry and particle size. Use grout formulations recommended for high-pressure double-liquid injection and consult the supplier if unsure.

14. Is there warranty or technical support available?

Warranty and support terms vary by supplier. Contact the seller or manufacturer for specifics on warranty coverage, spare parts availability, and technical assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals