B21, China Town Mall, Midrand

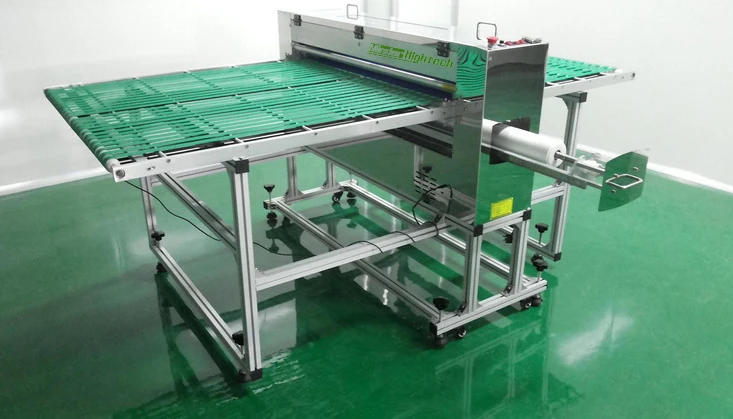

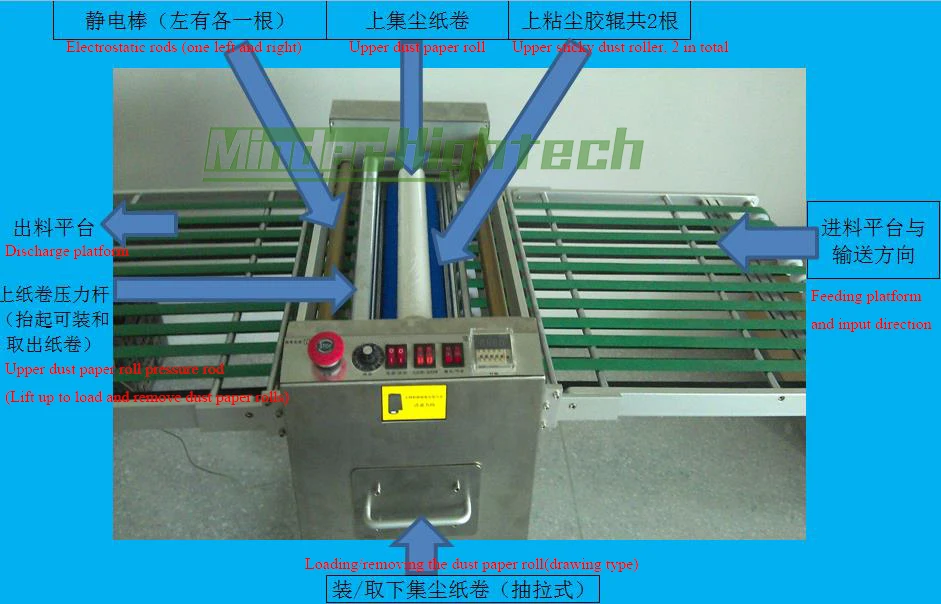

Electrostatic Dust Removal Machine Dust Collector for Sticker PVC PET

- Section : Machinery

- Category : Cleaning Equipment

- SKU : 1600895754894

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Electrostatic Dust Removal Machine clean?

The machine is effective for cleaning various materials including PVC, PET, optical sheets, films, PCB boards, and other soft board materials.

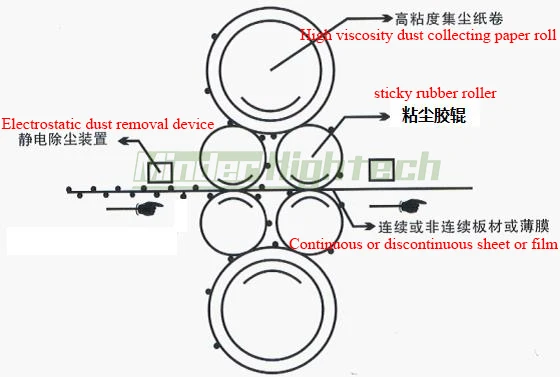

2. How does the machine eliminate static electricity?

It uses an AC Corona discharge type static elimination device, which effectively neutralizes static charges on surfaces.

3. What are the available models and their dimensions?

The available models are MD-L450, MD-L650, MD-L850, and MD-L1200, with dimensions ranging from 1260*790*1150mm to 2260*1540*1150mm.

4. What is the cleaning method used by the machine?

The machine features a double-sided cleaning method that removes dust and eliminates static from both sides of the material.

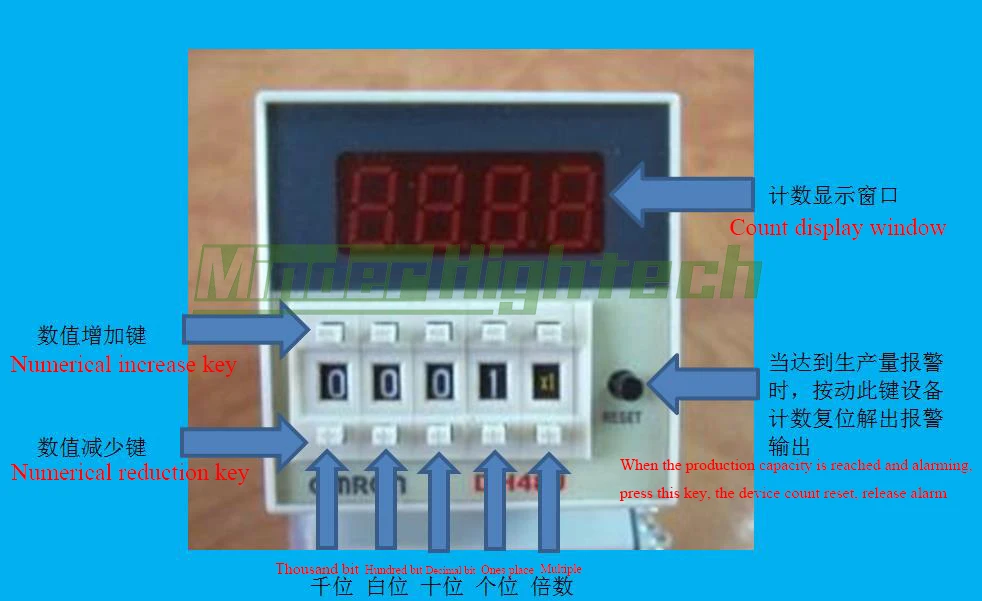

5. Can I customize the settings for the cleaning process?

Yes, the machine has customizable settings for cleanliness and includes alarm prompts for maintenance reminders.

6. What is the maximum film thickness the machine can handle?

The machine can accommodate film thicknesses ranging from 0.2mm to 3.2mm.

7. Is the operation of the machine automatic?

Yes, the machine features automatic operation with electric eye induction, making it easy to use.

8. What is the operating speed of the machine?

The operating speed ranges from 0 to 30 meters per minute.

9. What type of power supply does the machine require?

The machine requires an AC power supply of either 110V or 220V, single phase, 50/60HZ.

10. How many electrostatic eliminators are included in the machine?

The machine includes two electrostatic eliminators for enhanced static removal efficiency.

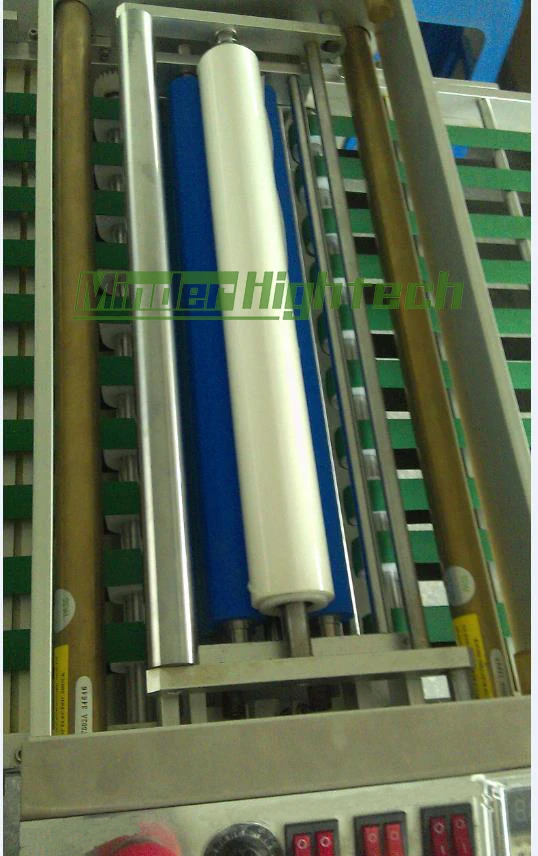

11. What is the dust removal roller size for each model?

The dust removal roller sizes vary: Φ40*450*4pcs for MD-L450, Φ40*650*4pcs for MD-L650, Φ40*850*4pcs for MD-L850, and Φ50*1200*4pcs for MD-L1200.

12. Can the machine be used as a standalone unit?

Yes, it can be used as a standalone unit or integrated into production lines.

13. What is the material of the conveyor wing?

The conveyor wing is made of an imported antistatic elastic belt.

14. What industries can benefit from this dust removal machine?

This machine is suitable for various industries that require effective static and dust control, including manufacturing and electronics.

15. How easy is it to replace the dust collecting paper roll?

The machine features a drawer-type device that allows for convenient cutting and replacement of the dust collecting paper roll.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading