B21, China Town Mall, Midrand

Electronic Standard Pendulum Impact Test Machine for Safety Glass Shock Test

- Section : Consumer Electronics

- Category : Test Instruments

- SKU : 62356951500

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the purpose of the Electronic Standard Pendulum Impact Test Machine?

The machine is designed to evaluate the impact resistance of safety glass by simulating various heights and conditions, ensuring the safety and durability of glass products.

2. What are the adjustable impact height options?

The impact height is adjustable from 12 to 48 inches (305 to 1220 mm), allowing for versatile testing scenarios.

3. What is the weight of the impactor used in the testing process?

The impactor weight is approximately 45.4 kg ±0.2 kg, which helps in simulating real-world impact conditions.

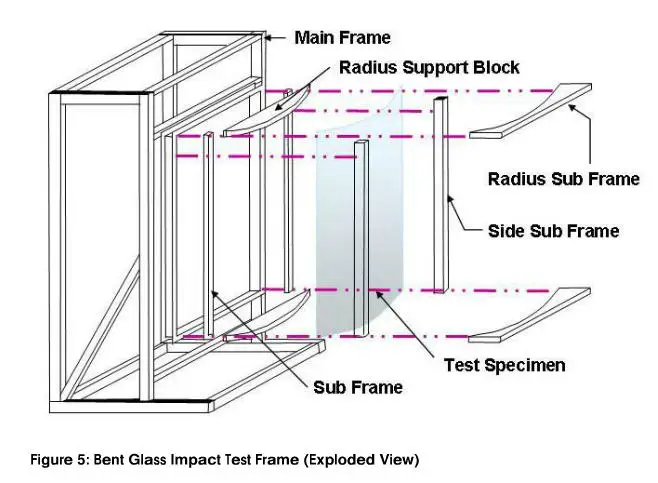

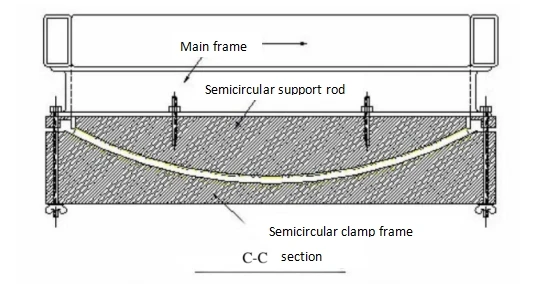

4. What is the maximum sample size that can be tested?

The machine can accommodate samples with dimensions of about H76in x W34in (H1930 x W865 ±2mm).

5. How does the electric lift feature work?

The electric lift allows for easy and precise height adjustments of the impact point, enhancing user convenience during testing.

6. What types of glass applications can this machine test?

It is suitable for testing safety glass used in automotive applications, buildings and facades, as well as for quality control in glass production.

7. Does the machine comply with industry safety standards?

Yes, the machine complies with multiple safety standards, ensuring reliable and consistent testing results.

8. What is the power requirement for the machine?

The machine requires a power supply of 1∮, AC220V, 5A for operation.

9. What materials are used in the construction of the machine?

High-quality materials are used to ensure the machine's durability and longevity in rigorous testing environments.

10. What is the role of the electromagnetic clutch in this device?

The electromagnetic clutch allows for precise control of the impact, contributing to accurate testing outcomes.

11. Is the swing arm adjustable?

Yes, the swing arm is adjustable to accommodate various impact heights, further enhancing testing flexibility.

12. What is the weight of the entire machine?

The total weight of the Electronic Standard Pendulum Impact Test Machine is approximately 750 kg.

13. Can this machine be used for research and development purposes?

Absolutely, this machine is ideal for research and development in glass manufacturing as well as for compliance testing.

14. What is the rubber strip size used in the machine?

The rubber strip size is W0.79in (20±2mm) in width, with a thickness of 0.39in (10±1mm) and hardness of 60±5 IRHD.

15. How do I maintain the machine for optimal performance?

Regular maintenance should include checking the electrical components, ensuring the impactor and swing arm are functioning correctly, and verifying calibration against industry standards.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals