B21, China Town Mall, Midrand

DZ-400/2S Automatic Filling and Sealing Machine

- Section : Machinery

- Category : Vacuum Packing Machines

- SKU : 1600687976791

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the DZ-400/2S Automatic Filling and Sealing Machine designed to do?

The DZ-400/2S is an electric-driven machine that automatically fills and vacuum-seals product packages. It is built for efficient, continuous small- to medium-scale packaging with a focus on durability, energy efficiency and ease of operation.

2. What types of products can this machine package?

It is suitable for liquids, powders, granules and other commodity products used in food & beverage, chemical and general commodity packaging. Packaging material must be compatible with vacuum sealing and the product’s physical properties.

3. What model/sizing options are available (sealing length, sealing width, chamber size)?

Sealing lengths are available in 400 mm, 500 mm and 600 mm with a standard sealing width of 10 mm. Typical chamber sizes (L×W×H) are approximately 435×420×40 mm (400 model), 525×420×40 mm (500 model) and 625×420×40 mm (600 model).

4. What power / voltage options does the machine support?

The machine uses an electric drive and can be configured for different regional power supplies. Common options include 110 V and 220 V; other configurations (such as 220/380 V) may be available—confirm exact voltage and Hz requirements with your supplier before ordering.

5. What are the vacuum pump specifications?

The DZ-400/2S uses a dual vacuum pump arrangement for faster evacuation. Typical rated capacity is around 20 m³/h per pump (dual-pump configuration). For motor power, exact values depend on model and region—refer to the detailed spec sheet from the manufacturer.

6. How does the double-chamber design work and what are the benefits?

The machine has two vacuum chambers that operate alternately. While one chamber is being vacuumed and sealed, the other can be loaded/unloaded—this increases effective throughput and supports continuous small-scale operation.

7. What is the machine’s weight and recommended installation requirements?

The unit is compact and weighs approximately 80 kg. It should be placed on a stable, level bench or worktable with adequate ventilation and a properly grounded power outlet sized to the machine’s configured voltage.

8. How do I operate the control panel and set sealing/vacuum parameters?

The control panel includes a vacuum gauge and controls to set vacuum time, deflation time, sealing time and sealing temperature. Operation is user-friendly—close the vacuum chamber cover, set parameters, and start the cycle. Consult the user manual for recommended settings by product type.

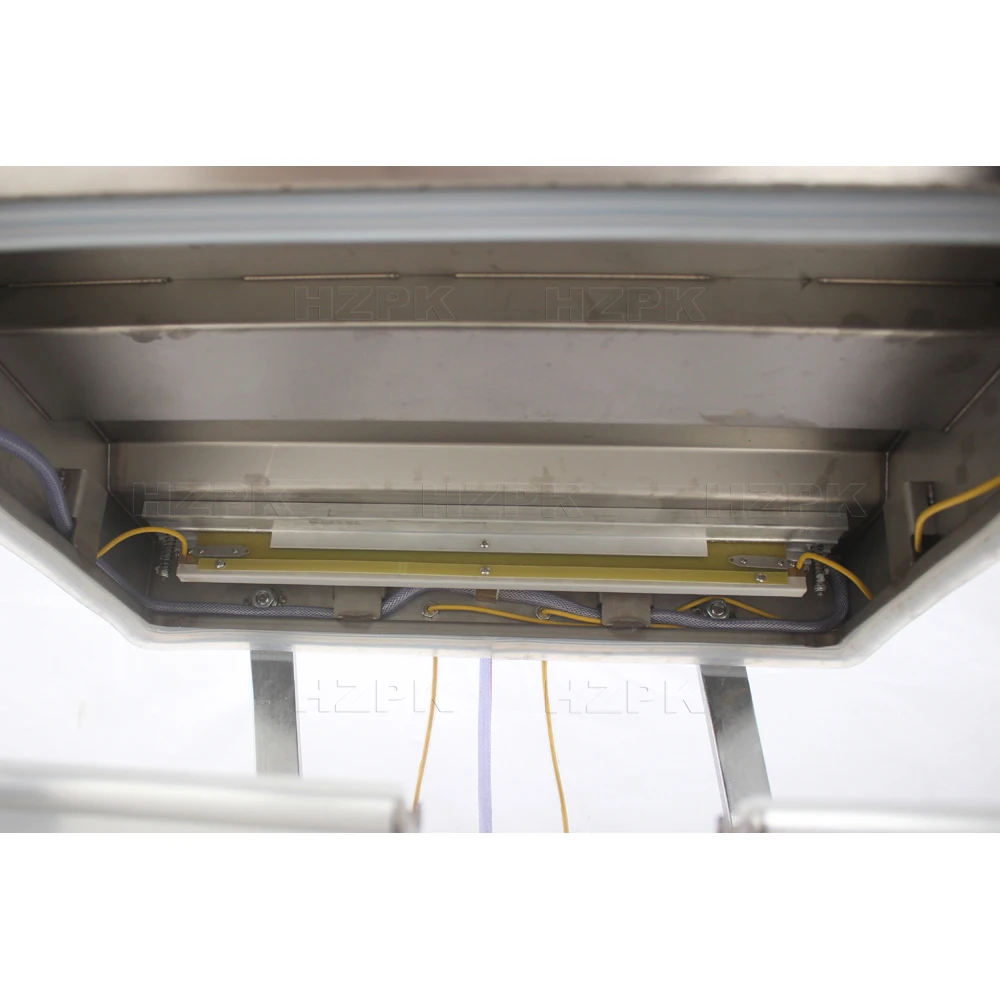

9. What maintenance does the machine require?

Regular maintenance includes cleaning the stainless-steel chamber, inspecting and replacing worn sealing strips, checking chamber gaskets for leaks, monitoring vacuum pump oil (if oil-lubricated) and keeping heating elements free of residue. Follow the manufacturer’s maintenance schedule for pump servicing.

10. What consumables and spare parts should I expect to replace?

Common consumables include heat-resistant rubber sealing strips, sealing tape, chamber gaskets and vacuum pump consumables (oil, filters). The manufacturer or distributor typically supplies replacement parts.

11. What safety precautions should operators follow?

Ensure the chamber cover is closed before starting a cycle, use the correct configured voltage and grounding, avoid sealing flammable or highly reactive materials without proper precautions, keep hands clear of sealing bars when active, and train operators in emergency stop procedures.

12. Can the machine handle liquid-filled packages and does it need additional equipment?

It can package liquids, but handling high-liquid or free-flowing liquids may require proper dosing/filling equipment and correct bag selection to prevent overflow during vacuuming. For heavy-liquid applications the supplier can advise on compatible fillers or process adjustments.

13. What after-sales support and documentation are provided?

The product comes with online and video technical support for setup, troubleshooting and maintenance. Warranty terms and on-site support options vary—check with your supplier for warranty length, coverage and spare-parts availability.

14. Can the machine be customized or upgraded?

Yes. Options commonly include different sealing lengths, chamber sizes, voltage configurations and accessory add-ons. Discuss specific customization or automation integrations with your supplier to match your production needs.

15. What are common troubleshooting tips for poor sealing or weak vacuum?

For poor seals: check sealing temperature/time, clean or replace worn sealing strips, verify proper bag placement and absence of debris on sealing surfaces. For weak vacuum: inspect chamber gasket for leaks, ensure vacuum pump is functioning and oil level/filters are correct. If the machine fails to start, verify power, emergency stop status and fuse/circuit protection.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading