B21, China Town Mall, Midrand

DTF Printer Roll To Roll Inkjet Printing Machine

- Section : Consumer Electronics

- Category : Digital Printers

- SKU : 1601045341617

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What exactly is the "DTF Printer Roll To Roll Inkjet Printing Machine"?

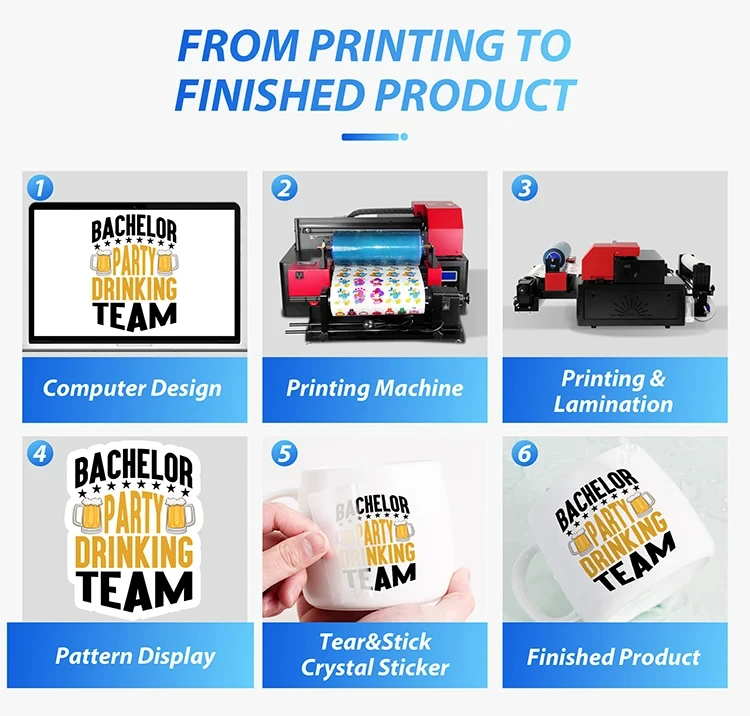

This machine is a roll-to-roll direct-to-film (DTF) inkjet printer designed to print full-color graphics onto PET transfer film for later heat-transfer to garments and textiles. The product description also references a UV flatbed variant (A3/A4 UV LED) — check the specific model you are ordering, as some suppliers offer both DTF roll-to-roll and UV flatbed configurations.

2. What materials can I print on with this machine?

DTF prints onto PET transfer film which is then applied to fabrics (cotton, polyester, blends, nylon, leather, etc.). If you choose a UV flatbed variant, UV ink can print directly on many rigid and flexible substrates (PVC, PC, PET, ABS, glass, wood, metal) often without pretreatment.

3. Can this printer print on dark garments or dark substrates?

Yes. Both DTF and UV systems can use white ink as an underprint layer. DTF prints CMYK plus white onto film to enable vibrant transfers on dark fabrics. UV printers with a white channel can print directly on dark or colored rigid substrates.

4. What ink configurations are available (colors, varnish, etc.)?

Common configurations include 4-color CMYK plus White and a Varnish/Gloss channel (e.g., 6 colors: C M Y K + W + Varnish). Some setups use double white or different varnish/clear options. Exact ink channels vary by model, so confirm the supplied ink set.

5. What is the varnish effect and can I get embossed or raised textures?

The varnish (clear) channel lets you print glossy or matte clear layers for highlights, protection, or visual effects. Multiple passes or thicker varnish layers can create a raised/embossed feel on the print (commonly used on UV flatbed machines).

6. Does the printer require substrate pretreatment or coating?

For DTF: you print onto film and then apply adhesive powder—no garment pretreatment is needed in most cases. For UV flatbed models: many materials can be printed directly without coating, but some substrates may still require primers or pretreatment for optimal adhesion—check material-specific recommendations.

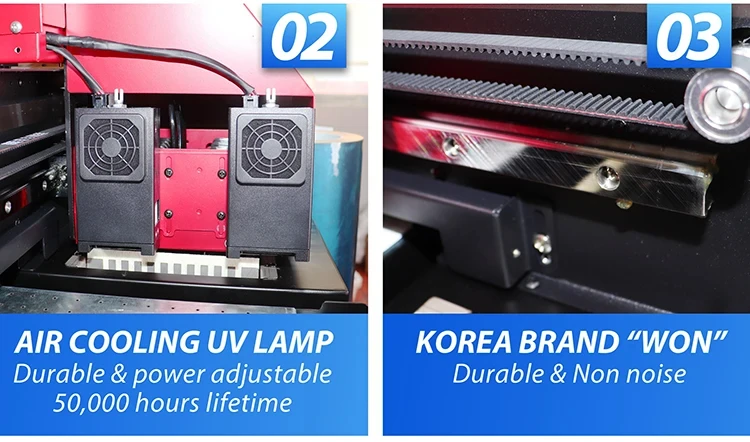

7. How is the ink cured or dried?

DTF inks are typically water-based/pigment inks that are dried and then heat-transferred and cured with a heat press. UV flatbed models use UV-curable inks that are instantly cured by integrated UV LED lamps as the ink is printed.

8. What print sizes and media widths does this roll-to-roll model support?

Roll-to-roll DTF models come in various widths. The product description mentions A3/A4 for the flatbed variant; roll widths for DTF typically range from 330 mm up to 1.6 m or more depending on model. Confirm the exact roll width and max printable height with your supplier.

9. What print quality (resolution) and speed can I expect?

Quality and speed depend on the chosen print mode and model. These machines typically support high-resolution output (for example up to 1440 dpi or similar) with variable-speed modes (draft to high quality). Ask the vendor for typical m2/hr at each quality setting for the exact model.

10. What software and file formats are supported?

Most machines work with common RIP software that handles color management, white-channel generation, and varnish mapping. Supported file formats usually include TIFF, PNG (with transparency), PSD, PDF, and sometimes direct printing from RIP. Confirm the included RIP and supported workflows.

11. What routine maintenance is required?

Key maintenance includes daily/regular printhead cleaning cycles, white-ink circulation/agitation to prevent sedimentation, cleaning or replacing ink filters, checking heating and air systems for DTF drying, and keeping the platen/rollers clean. Follow the supplier's maintenance schedule for longevity.

12. How is white ink handled to avoid clogging or settling?

White ink must be agitated or circulated regularly to prevent pigment settling. Many machines include a white-ink circulation system and periodic automated cleaning routines. Manual mixing/recirculation and scheduled head cleans are crucial to avoid clogging.

13. What consumables and spare parts should I budget for?

Typical consumables: inks (CMYK, White, Varnish), PET transfer film (for DTF), adhesive powder (DTF), cleaning solutions, printhead cleaning cartridges, wiper blades, drive belts/rollers, and replacement printheads over time. Costs vary by usage and region—request a parts/consumables price list from the supplier.

14. Can this machine print special effects like spot gloss or multi-layer prints?

Yes. Machines with a dedicated varnish channel can print spot gloss/clear effects. Multi-pass printing with white and varnish allows layered prints and texture/emboss-like effects. DTF workflows enable vivid multi-layer transfers; UV flatbeds can build tactile effects with thicker varnish passes.

15. What warranty, installation, and training/support are provided?

Warranty, installation, and training vary by supplier. Many vendors offer on-site installation, operator training, spare parts, and technical support (remote or on-site) for a set warranty period. Confirm warranty length, what it covers, response times, and availability of local service before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading