B21, China Town Mall, Midrand

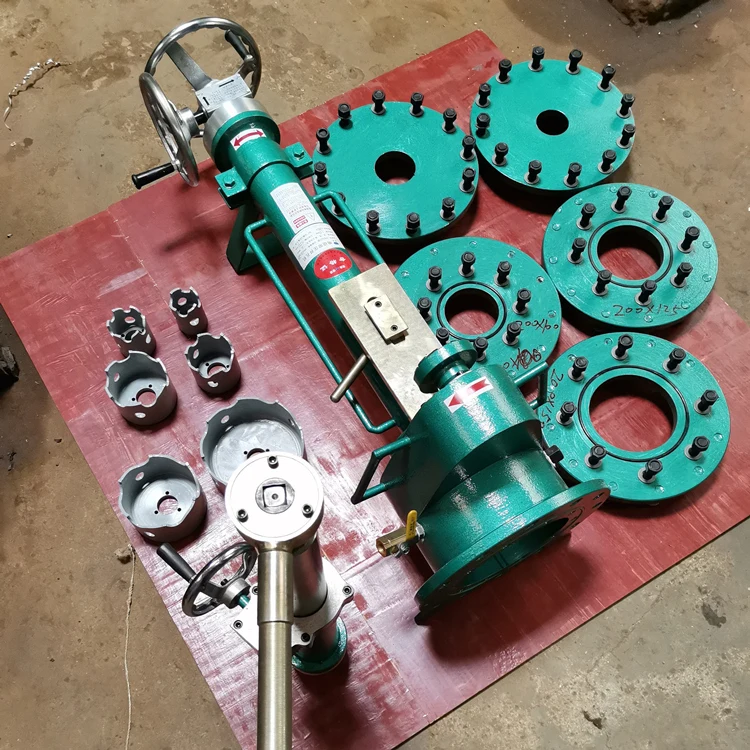

DN600 Electric Drive Hot Tapping Machine Pipedrill Equipment for Water Pipe Hot Tapping

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600696707150

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the DN600 Electric Drive Hot Tapping Machine?

The DN600 Electric Drive Hot Tapping Machine is a pipedrill hot tapping system designed to drill and tap pressurized pipelines (water, gas, petrochemical) without stopping flow. The DN600 model is an electric-driven unit suitable for in‑service tapping up to 600 mm nominal pipe diameter.

2. Which pipe materials and industries is this machine suitable for?

It is suitable for metal, cement (concrete-lined), and plastic pipes used in water, gas, petrochemical and other pipeline transportation industries where in-service hot tapping is required.

3. What pipeline sizes are available and which size does DN600 cover?

The product line includes models DN100, DN200, DN400, DN600 and DN800. The DN600 model is intended for tapping pipelines up to approximately DN600 (nominal 600 mm). For larger or smaller diameters select the matching model.

4. What is the working pressure range for the DN600 machine?

The standard working pressure range for these machines is 10–25 bar. Always verify the pipeline pressure and ensure it is within the machine's rated limits before tapping.

5. What are the key technical specifications of the DN600 model?

DN600 key specs: bit shank options 500/600 mm, stroke 900 mm, spindle speed 25 r/min, power 4 kW, voltage 380 V, typical tapping time 30–60 minutes (depending on pipe material and conditions).

6. What components are included with the machine?

Standard product configuration includes the host (drive) machine, drill/tapping bit, and a matching flange. Additional accessories or adaptors may be available on request.

7. Is there a manual (non-electric) option?

Yes. The product line references both electric drive and manual tapping machines. Contact the supplier if you require a manual model or a hybrid configuration.

8. How long does a typical hot tap take with the DN600?

Typical tapping time for the DN600 is 30–60 minutes, but actual time depends on pipe material, wall thickness, bit condition and site conditions.

9. Can the machine perform hot taps on pressurized lines safely?

Yes—this machine is designed for live (hot) tapping. However it must only be used within its rated working pressure (10–25 bar), fitted to the correct flange and valve assembly, and operated by trained personnel following safety procedures.

10. What power supply and electrical requirements are needed?

The DN600 model requires a 380 V power supply. Other models in the range may accept 220/380 V—confirm the specific model and local electrical standards before installation.

11. What are the basic installation and operation recommendations?

General recommendations: fit the correct matching flange and gasket, ensure secure mechanical mounting, verify pipeline pressure and isolation valves, connect proper power supply, align the tool before starting, and perform the tap with trained personnel. Follow site safety rules and manufacturer instructions.

12. What maintenance is required for the hot tapping machine?

Routine maintenance includes inspecting and replacing worn cutting bits, checking seals and gaskets, lubricating moving parts, verifying spindle and gearbox condition, and cleaning after use. Replace any damaged parts and store the unit dry. Follow the manufacturer's maintenance schedule.

13. Are spare parts and different drill/cutter sizes available?

Yes. Spare parts and a range of drill bit shank sizes (model-dependent—for DN600 common shanks 500/600) are available. Contact the supplier for compatible cutters, adaptors and consumables.

14. What safety precautions should operators follow?

Operators should wear appropriate PPE, confirm pipeline pressures, ensure proper flange and valve assemblies, use only trained personnel, have an emergency shutdown procedure, and follow lockout/tagout and local regulations. Never exceed rated pressure or force the equipment.

15. What certifications, warranty and support are available?

Certification, warranty terms and after‑sales support may vary by supplier and region. Please contact the sales or technical representative for copies of certificates (e.g., CE, ISO if available), warranty details and service/repair options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading