B21, China Town Mall, Midrand

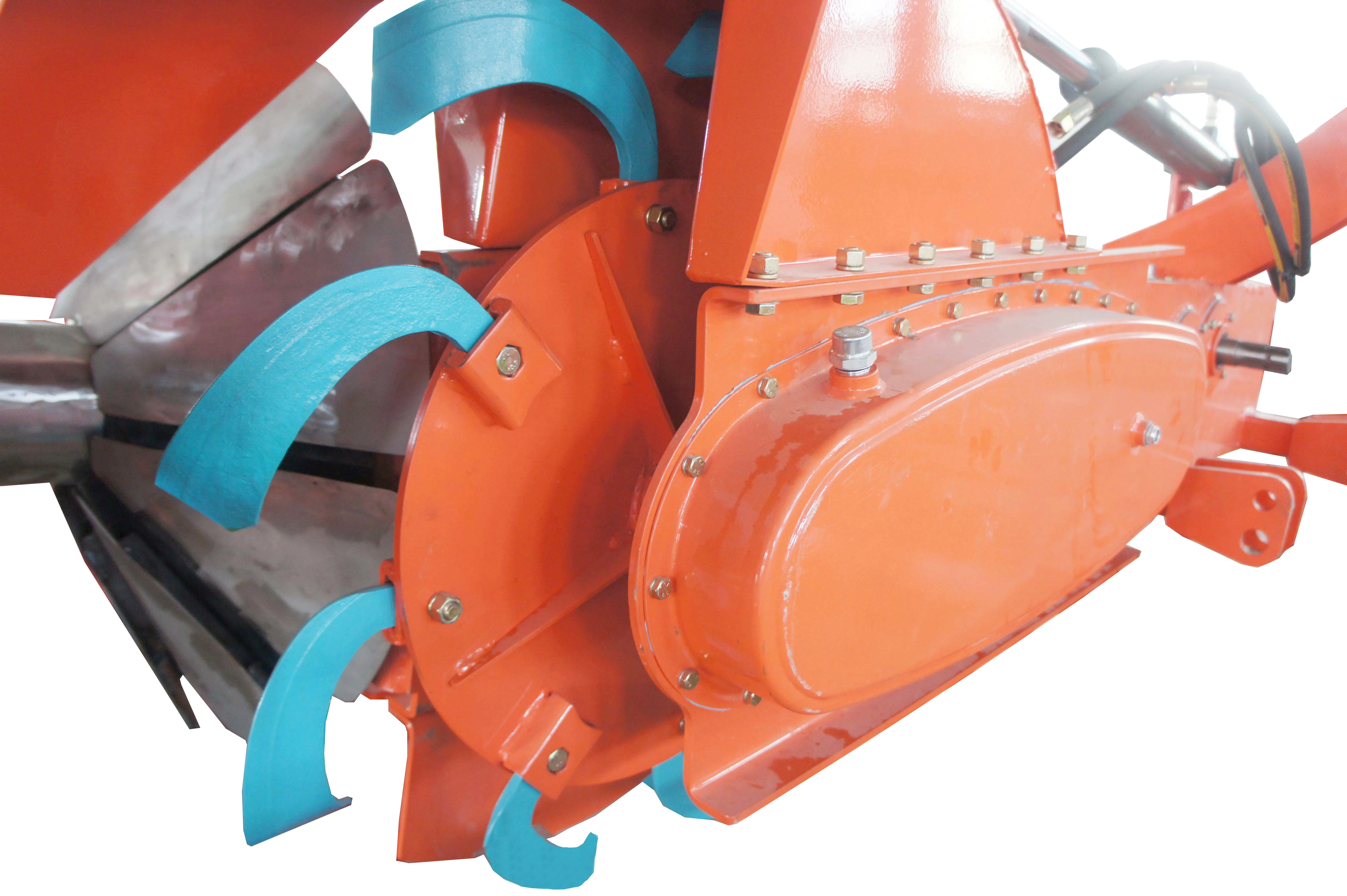

Diesel-Powered Rice Field Ridger Making Machine for Efficient Farm Cultivation

- Section : Machinery

- Category : Cultivators & Ploughs

- SKU : 1600579189181

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Diesel-Powered Rice Field Ridger Making Machine?

A rear-mounted ridger designed for creating ridges in paddy and rice fields. It is diesel-powered with a gearbox transmission, built for durability and efficient ridging in wet rice farmland.

2. What engine powers this ridger?

The machine is powered by a diesel engine (core component), chosen for strength and reliability in demanding field conditions.

3. Which tractors is this ridger compatible with?

It is rear-mounted and compatible with standard 3-point linkage tractors rated between 70 and 110 HP.

4. What type of transmission does the machine use?

It uses a gearbox transmission with gear and shaft drive. The drive system is gear/shaft-driven — not chain-driven — for smooth, consistent operation.

5. What is the travel/working speed of the machine?

Typical operating travel speed is approximately 1500–2000 meters per hour, allowing efficient completion of ridging tasks.

6. Is this machine suitable for paddy and other wet field conditions?

Yes. It is specifically designed for paddy fields and rice farmlands, optimized to operate in wet, soft soils common to rice cultivation.

7. What are the machine dimensions and storage requirements?

Overall dimensions are approximately 1050 mm (H) x 2330 mm (W) x 1000 mm (D). Its compact footprint makes it relatively easy to store on a farm when not in use.

8. What warranty is provided?

Core components such as the engine and gearbox are covered by a 1-year spare parts warranty. Check with your supplier for full warranty terms and coverage details.

9. What routine maintenance is required?

Regular maintenance includes checking/changing engine oil and filters, inspecting gearbox oil level, tightening fasteners, cleaning mud/debris after use, and inspecting/servicing rotary blades for wear.

10. How is the ridger mounted and connected to a tractor?

It mounts to the tractor's rear 3-point linkage. The suspension is similar to a tiller and requires connection to the tractor hydraulic quick outlet for lifting/angle control as applicable.

11. Tell me about the blades and cutting components.

The machine uses high-quality, international-standard rotary blades designed for effective ridging. Blades are serviceable and can be sharpened or replaced as they wear.

12. Can it handle hard, rocky or overly compacted soils?

The ridger is optimized for soft, waterlogged paddy soils. Extremely rocky or heavily compacted soils can reduce performance and increase wear; clearing large stones and assessing soil conditions beforehand is recommended.

13. What safety precautions should operators take?

Ensure the ridger is securely attached to the tractor, follow tractor and implement PTO/hydraulic safety procedures, keep bystanders clear while operating, inspect parts before use, and operate at safe speeds for field conditions.

14. Are spare parts and service available locally?

Spare parts for core components are covered by warranty and are typically available through the supplier or authorized dealers. Contact your vendor for local parts availability and after-sales service.

15. What color is the machine and does it have visibility features?

The machine is finished in a vibrant red color, which improves visibility in the field and makes it easier to spot among other equipment.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading