B21, China Town Mall, Midrand

Diesel Wall Cement Plastering Mortar Spraying Machine

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 11000001390211

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Diesel Wall Cement Plastering Mortar Spraying Machine (SL-700) used for?

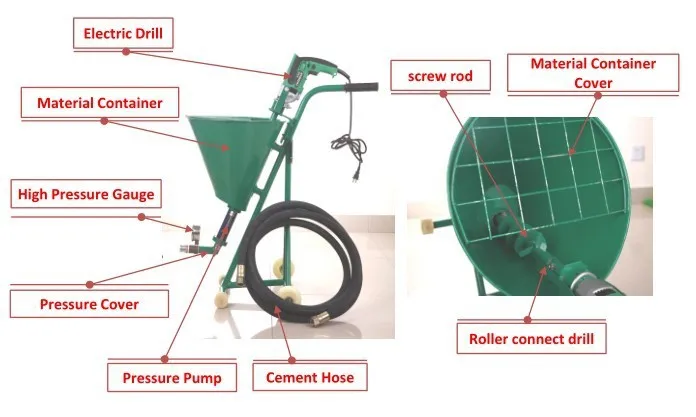

The SL-700 is designed for spraying cement mortar, putty, dry powder mortar, waterproof coatings and similar materials (granules <2 mm). Typical uses include leak sealing (expansion joints, tunnels, dams), structure strengthening (bridges, terraces), interior/exterior wall and ceiling spraying, decorative finishes and grouting/injection work.

2. What are the key technical specifications of the SL-700?

Net/Gross weight: 21 / 27 kg; Drill power: 800 W / 220 V; Flow: 1–10 L/min; Granular size: <2 mm; Speed: 0–1200 RPM; Pressure: 20 kg (pump); Packing size: 78 × 51 × 96 cm.

3. Which materials can I spray or inject with this machine?

Suitable materials include cement mortar, putty powder, emulsion paint and waterproof coating materials, as long as particle size is under 2 mm and the material is mixed to a pumpable consistency.

4. What air compressor do I need to operate the sprayer?

Before spraying, the air compressor pressure should reach about 8 kg (as stated in the manual). The recommended air supply range in the manual is 0.26–0.36 (check the unit and local spec). Use an air compressor that can reliably supply this pressure and the necessary flow for consistent atomization.

5. How do I prepare the machine before spraying?

Pour clean water into the material hopper and run at mid-high speed briefly to wet the hose, then drain. Mix materials thoroughly, load into the hopper, securely connect hoses and spray gun, ensure compressor pressure is correct, then adjust rotating speed and air pressure while spraying into the hopper to set the spray pattern before moving to the work surface.

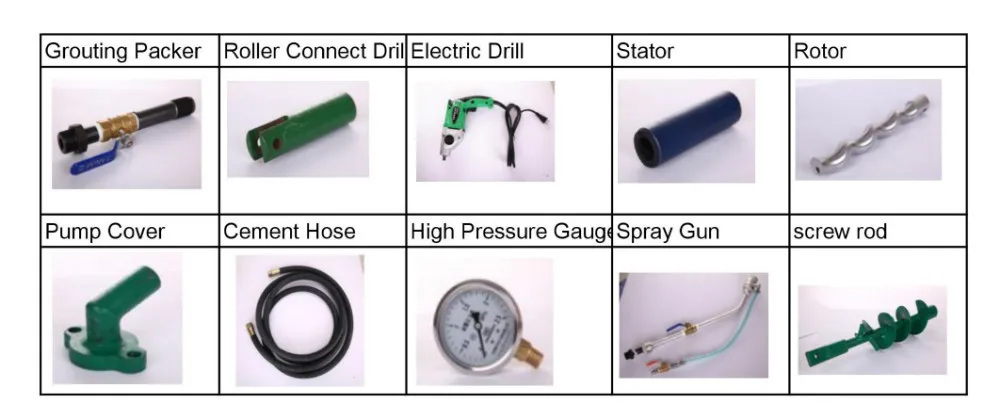

6. What are the steps for grouting/injection with the packer?

Lubricate the new injection pump, load mixed cement into the cup, vent lubricant through the hose until material flows, drill 16 mm holes spaced 50–100 cm along the joint, insert and clamp grouting packers, connect injector, turn on valve and power, inject until overflow, then move to the next hole. Clean immediately after finishing.

7. How do I clean and maintain the machine after use?

Clean the material barrel, hose, spray nozzle and joints after work. For the injector, run a special cleanser through the pump and hose, cycle the valve several times to create pressure, then expel cleanser. Lubricate pumps and moving parts regularly to prevent residue build-up. Replace the pressure pump if worn.

8. How do I unclog the spray nozzle or hose if material stops flowing?

If nozzle blockage occurs, switch off power and clean the spray nozzle thoroughly. If the drill runs but nothing sprays, check the nozzle for blockage. Also ensure hoses are not kinked and material is properly mixed and filtered (granules <2 mm).

9. What troubleshooting steps should I take if the sprayer won't start?

Check the electrical driving drill (motor) and power connections. If the drill is burned out, replace it. Ensure the main switch is in the OFF position before inspecting or replacing components. Verify air compressor is supplying required pressure.

10. Are spare parts and accessories included with the machine?

Standard equipment includes machine body, electrical drill, high pressure gauge, spray gun, grouting packer, cement hose, a set of spare parts and an instruction booklet.

11. Is the machine portable and easy to move on site?

Yes. The SL-700 has an iron body with four wheels for portability. At 21 kg net weight it is relatively easy to transport around the jobsite.

12. What operator safety precautions should I follow?

Do not wet electrical components (drill or control box). When disconnecting a pressurized hose, cover it with cloth to protect eyes from material spray. Avoid letting the machine run idle with hose full of material. Follow standard PPE: goggles, gloves, dust mask/respirator and hearing protection.

13. How should I store the machine between jobs or long-term?

Clean and flush all material from hopper, hoses and pump with appropriate cleanser, lubricate moving parts and pumps, store in a dry place protected from dust and moisture. Remove electrical drill if storing for long periods.

14. What routine parts may need replacement and how often?

Wear parts include the pressure pump, gaskets/seals and spray/nozzle components. Frequency depends on usage and abrasive content of materials; inspect regularly and replace worn parts to maintain performance.

15. Where can I get service, spare parts or warranty information?

Refer to the instruction booklet for supplier contact details. For warranty, service and genuine spare parts contact your vendor or the manufacturer's authorized service center listed in the manual.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading