B21, China Town Mall, Midrand

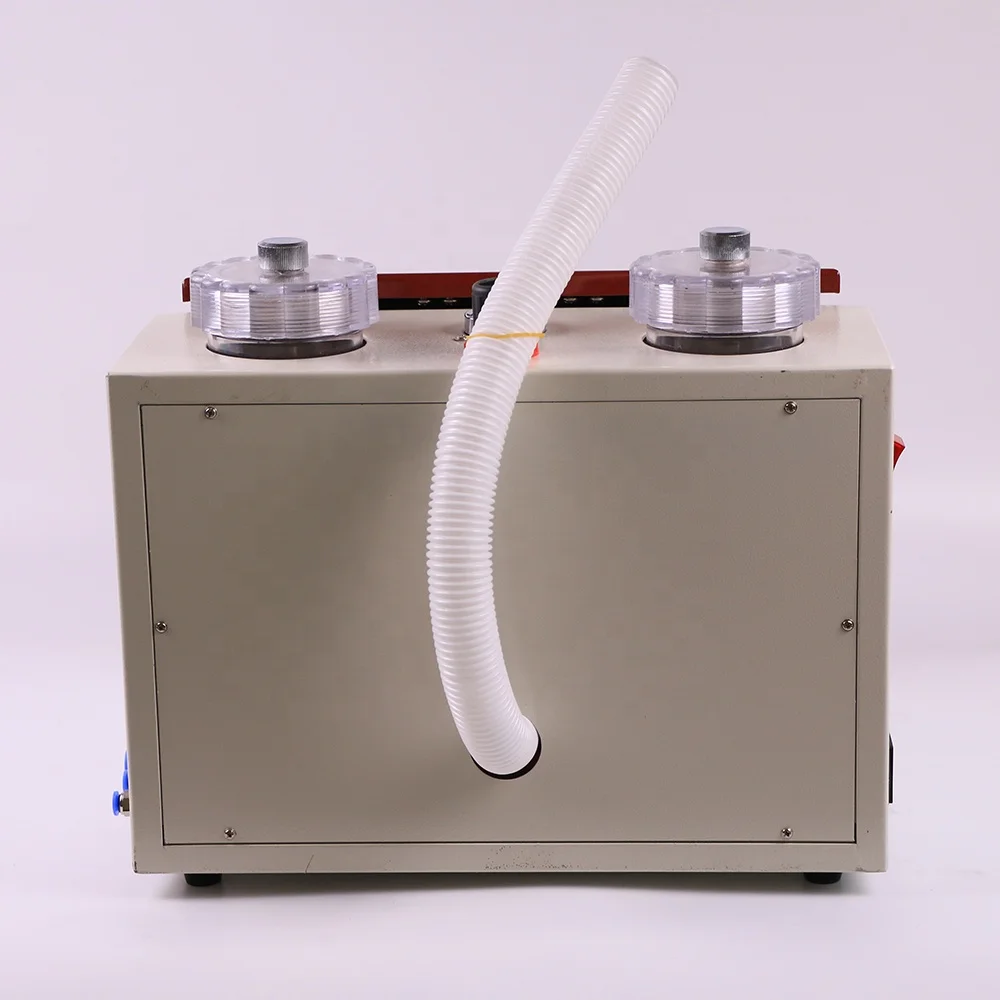

Dental Sandblasting Machine

- Section : Medical Supplies

- Category : Dental Equipments

- SKU : 1600682223100

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 25 Dec, 2025, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a dental sandblasting machine used for?

A dental sandblasting machine is primarily used for surface sandblasting treatment of small cast parts, gold and silver jewelry, and other jewelry items. It helps in cleaning molds, forging parts, welding parts, and preparing surfaces for electroplating.

2. What are the key features of this machine?

Key features include its capability to perform sandblasting on various materials, a built-in light for low-light conditions, and suitability for medium and small parts in both single piece and mass production.

3. What materials can be sandblasted with this machine?

This machine can sandblast materials such as gold, silver, glass, and plastic, as well as perform carbide removal and finish treatment on various mechanical parts.

4. What is the power requirement for the dental sandblasting machine?

The machine operates on a voltage of 110~220V with a power rate of 50W, and it has a lamp power of 25W.

5. What is the pressure requirement for this machine?

The machine requires a minimum pressure of 4 kg for optimal operation.

6. What is the size of the sand used in the machine?

The sand size requirement is 120 mesh or finer for effective sandblasting.

7. How much does the dental sandblasting machine weigh?

The machine weighs 16 kg.

8. What are the dimensions of the dental sandblasting machine?

The dimensions of the machine are 46 cm in length, 48 cm in width, and 35 cm in height.

9. Can this machine be used for polishing porcelain crowns?

Yes, the machine is suitable for polishing porcelain crowns as part of its sandblasting capabilities.

10. How do I operate the dental sandblasting machine?

To operate, insert the pipe joints, connect the power cord and foot switch, fill the sand cup appropriately, and adjust the pressure regulator to ensure it exceeds 0.4 MPa before use.

11. Is the machine suitable for both single piece and mass production?

Yes, the dental sandblasting machine is suitable for both single piece and mass production of medium and small parts.

12. What safety precautions should I take while using the machine?

Always wear appropriate safety gear, including goggles and a dust mask. Ensure proper ventilation in the workspace and follow the manufacturer's operating instructions for safe use.

13. Can I adjust the direction of the sandblasting?

Yes, the machine allows you to adjust the direction for left and right pen sandblasting as needed.

14. What should I do if the sandblasting effect is poor?

Check that the sand cup is filled correctly, ensure the sand pipe is not blocked, and verify that the pressure is set above 0.4 MPa for optimal performance.

15. What is the warranty period for the dental sandblasting machine?

Please refer to the manufacturer's documentation for warranty details, as warranty periods can vary based on the seller and location.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals