B21, China Town Mall, Midrand

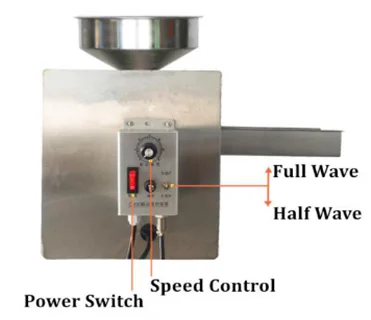

DAOHANG 2019 Upgraded Sunflower Seeds Oil Press Machine

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 60827429426-1710849215

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the processing capacity of the DAOHANG 2019 Upgraded Sunflower Seeds Oil Press Machine?

The machine has a typical capacity of 15–20 kg per hour. Actual throughput depends on seed type, moisture content, pretreatment (e.g., roasting), and selected operating mode (cold or hot pressing).

2. Which seeds and nuts can this oil press process?

It can extract oil from a wide range of seeds and nuts including sunflower, peanut, flaxseed, soybean, rapeseed, tea seed, basil, sesame, pinenut, almond, walnut, coconut, and palm.

3. Does the machine support cold pressing and hot pressing?

Yes — the machine supports both cold and hot pressing. Cold pressing preserves more natural flavor and nutrients, while hot pressing (with seed preheating or built-in heating if applicable) usually increases oil yield.

4. What power supply and power consumption does the machine require?

The unit operates at a total power of 3 kW. Voltage and phase options may vary by model or market — please check the product listing or contact the seller for specific voltage (e.g., 110V/220V/380V) and plug requirements.

5. What materials is the machine made from?

The frame and oil-contacting components are made of stainless steel (food-grade where applicable) for corrosion resistance, ease of cleaning, and hygienic oil production. The motor uses imported pure copper for durability and reduced noise.

6. How do I prepare seeds before pressing?

Typical preparation includes cleaning (removing stones, debris), drying to an appropriate moisture level, and optionally dehulling hard seeds. For hot pressing, seeds are often lightly roasted or preheated to improve yield and flavor. Preparation requirements vary by seed type.

7. What oil yield can I expect?

Yield varies by seed species and pretreatment. Generally expect yields in a broad range depending on the seed oil content and processing method (cold vs hot). For best estimates for a specific seed, test a small batch or consult seller documentation.

8. Is the machine easy to operate and does it have automatic features?

Yes. The DAOHANG features an automatic electric feeder for stable feeding and consistent output, reducing manual work. Basic operation involves powering on, adjusting settings (if needed), feeding seeds, and collecting oil and cake.

9. How do I clean and maintain the press?

Turn off and unplug the machine before cleaning. Remove and clean oil-contact parts with warm water and food-safe detergent; do not immerse electrical components or motor. Wipe the exterior stainless steel frame dry. Regularly inspect and tighten fasteners, check the press shaft and chamber for wear, and follow any lubrication schedule in the manual.

10. What are the machine dimensions and weight?

Dimensions are 900 mm × 320 mm × 800 mm and the machine weighs approximately 68 kg, making it suitable for small-scale production and compact workspaces.

11. Is the machine certified and safe to use?

The product description notes CE certification and a design patent. For electrical safety and compliance in your country, verify the specific certification details with the seller or supplier and ensure the correct voltage/plug configuration is provided.

12. How noisy is the machine during operation?

The machine uses a pure copper imported motor described as 'noiseless and durable.' While it is quieter than many older models, some operational noise is normal. Actual noise levels depend on load and installation.

13. Are spare parts and after-sales support available?

Spare parts availability and warranty terms are not specified in the listing. Contact the seller or distributor for information on spare parts, maintenance kits, lead times, and warranty or after-sales service policies.

14. Can I use this machine for commercial production?

Yes — it is suitable for small-scale commercial or on-site production (e.g., artisanal oil production, farm use, or small factories). For larger-scale industrial production, evaluate throughput needs and consider larger commercial models.

15. What safety precautions should I follow when using the press?

Always keep hands and loose clothing away from moving parts, switch off and unplug the machine before maintenance or cleaning, operate on a stable surface, ensure proper grounding and electrical protection, and keep children away from the machine during operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading