B21, China Town Mall, Midrand

CY-MACH Poultry Farming Auto Feed Screw Conveyor Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1601032588589

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the CY-MACH Poultry Farming Auto Feed Screw Conveyor Machine used for?

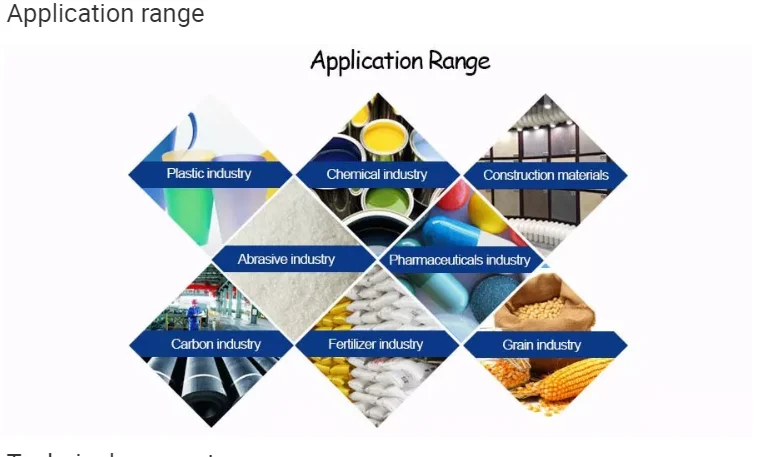

It is designed for continuous, efficient conveying of powder and granular materials (for example poultry feed, meal, powdery raw materials) in poultry farms and other industries such as metallurgy and building materials.

2. What conveying capacity does the machine offer?

The machine has a nominal capacity range of about 4 to 11 tons per hour, depending on the model and the bulk density/flow properties of the material being conveyed.

3. What models and size options are available?

CY-MACH offers multiple models to match different throughput needs (common model sizes include 100, 160, 200, 250, 315, 500, 630, 800 and 1000). Capacity, screw pitch and rotational speed vary by model; consult the full specification sheet or your sales contact for model-to-capacity matching.

4. What are the key mechanical specifications?

Key features include a screw-pitch in the range shown for different models (roughly 100–560 mm depending on model), varying screw speeds by model, and a machine weight of about 680 kg for the standard configuration. Exact specs depend on the selected model.

5. What type of motor does it use and what is frequency conversion?

The unit is equipped with a frequency-conversion (variable-frequency) motor, which allows smooth start/stop, adjustable screw speed to match feed rate requirements, and improved energy efficiency compared with fixed-speed motors.

6. Which feed types can it handle (pellets, mash, powder)?

The conveyor is intended primarily for powder and small granular materials (mash and fine particles). It can handle pelletized feed depending on pellet size and hardness, but very large or fragile pellets may require special consideration—test with your product or consult CY-MACH for recommendations.

7. Can the machine be customized (color, dimensions, materials)?

Yes—color and a number of specifications are customizable to customer requirements. Material of construction or other special options (e.g., stainless steel contact surfaces) can often be provided upon request; discuss specific customization needs with sales.

8. What are the installation requirements?

Installation typically requires a stable, level foundation and proper anchoring points for the conveyor. Orientation and inlet/outlet positions must be coordinated with your existing feeding system. Electrical connection to the specified motor supply is required. CY-MACH or an authorized dealer can provide installation guidance or services.

9. How is the machine cleaned and maintained?

Routine maintenance includes periodic inspection of the screw, trough, bearings, seals and motor; removal of accumulated material; lubrication of bearings as specified; and checking fasteners. For cleaning, follow procedures appropriate for the feed type—mechanical removal then wiping or low-pressure wash if materials and seals permit. Always follow lockout/tagout and manufacturer cleaning instructions.

10. What safety features are provided?

Standard safety considerations include guarded rotating parts, electrical protection for the motor and VFD, and provisions for safe access during maintenance. Specific safety guards, emergency stops and interlocks can be added per application and local regulations.

11. How noisy is the conveyor and are there vibration concerns?

Noise and vibration levels are typical for an industrial screw conveyor and depend on model, installation and material handled. Vibration can be minimized with proper mounting, correct alignment, and periodic maintenance. If low-noise operation is critical, discuss isolation or noise-reduction options with CY-MACH.

12. Are spare parts and after-sales service available?

Yes—spare parts (screws, bearings, seals, motor components) and after-sales service are typically available. Contact your CY-MACH distributor or sales representative for recommended spare parts, lead times and service contracts.

13. What power supply and electrical requirements are needed?

Electrical requirements depend on the chosen model and motor rating. The machine uses a frequency-conversion motor, so supply voltage, phase and motor kW rating must be specified at order. CY-MACH will provide detailed electrical specs for the selected model.

14. How do I choose the right model for my farm or plant?

Select a model based on required throughput (tons/hour or m3/hour), material bulk density, conveyance distance/vertical lift, and installation footprint. Provide CY-MACH with your feed type, required feed rate, and layout for a recommended model and configuration.

15. What are typical lead time and warranty terms?

Lead time and warranty vary by order size, customization and stock. Standard warranty and lead-time details are provided at the time of quotation—contact CY-MACH or your local distributor for current lead times and the specific warranty applicable to your purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading