B21, China Town Mall, Midrand

Chicken Cages Poultry Cage Egg Laying Hen Cages For Chicken Farming SLD

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 1601219370615

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

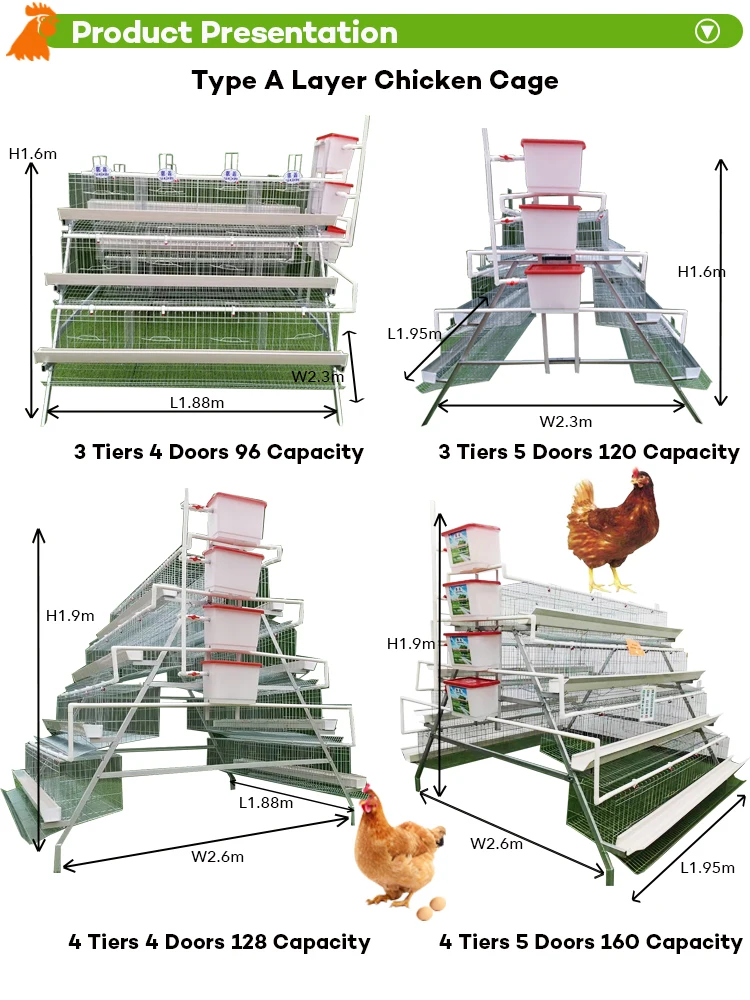

1. What is the capacity of the chicken cages?

The chicken cages come in various capacities, ranging from 96 birds in a 3-tier, 4-door configuration to 250 birds in a 5-tier, 5-door configuration.

2. What materials are used to make the chicken cages?

The cages are made from low carbon steel wire, specifically Q195 and Q235 steel wire.

3. How long do the chicken cages last?

The lifespan of the cages varies with the surface treatment: Cold Galvanization lasts 7-10 years, while Hot Dip Galvanization and PVC Coating can last 15-20 years.

4. What are the dimensions of the cages?

Cage sizes vary based on the model, for example, a 3-tier, 4-door cage measures 1.88m x 2.1m x 1.6m.

5. How can I customize the chicken cages?

Cage making can be customized according to clients' requirements, ensuring you get a cage that fits your specific needs.

6. What features do these chicken cages offer?

Features include increased egg production, independent cells for uniform feeding, easy waste handling, and a fully automated drinking water system.

7. How does the design of the cage help in reducing disease transmission?

The design allows feces to fall directly to the ground without direct contact with chickens, reducing the chance of infection.

8. Is the cage easy to handle and maintain?

Yes, the cage design facilitates easy handling of chicken waste and efficient maintenance, making it user-friendly for farmers.

9. What is the egg production rate with these cages?

The cages are designed to increase egg production to 98%.

10. Are the drinking water systems safe for the chickens?

Yes, the food-grade drinking fountain needles ensure the safety of the water, allowing for safe consumption by the chickens.

11. How do I receive my order?

For full container loading, cages and frames are shipped without packaging, while less container loading options are packed in wooden boxes and pallets.

12. What is the height of the cages?

The cages are designed to be 2 meters in height, making it suitable for farmers to feed chickens and collect eggs comfortably.

13. Can I order a cage with specific dimensions?

Yes, you can request customization for specific dimensions when placing your order.

14. What should I do if I encounter issues with the cage?

For any issues, please contact our customer support for assistance with troubleshooting and solutions.

15. How does the tilted chicken cage feature work?

The tilted cage at the bottom allows eggs to roll directly into the egg receiving slot, minimizing the risk of damage to the eggs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading