B21, China Town Mall, Midrand

CH-60L Hydraulic Hole Puncher Tools (WITH PUMP)

- Section : Electrical & Tools

- Category : Hydraulic Tools

- SKU : 1600990359039

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the CH-60L Hydraulic Hole Puncher (WITH PUMP)?

The CH-60L is a hydraulic hole puncher supplied with a matching hydraulic pump. It's a portable tool designed to punch clean holes in sheet materials using interchangeable punch-and-die sets.

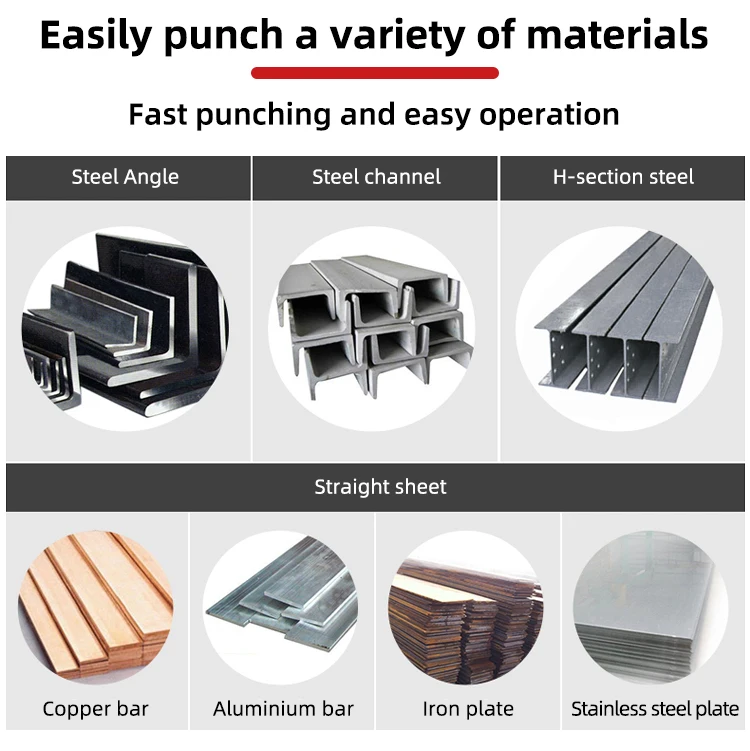

2. What materials can this hole puncher work with?

It is commonly used on mild steel, stainless steel, aluminum, copper and many plastics. Maximum material type and thickness depend on the selected punch/die set and the tool's rated capacity—refer to the product specifications or manual for details.

3. Does the pump come included and what type is it?

Yes — the product is sold with a hydraulic pump. The pump is a manual hand (or lever) hydraulic pump designed to provide the pressure needed to operate the punch safely and reliably.

4. What hole sizes can the CH-60L produce?

Hole size capability depends on the punch-and-die sets used. The CH-60L accepts standard punch sets within its capacity range; consult the seller or manual for a list of compatible diameters.

5. How thick a plate can it punch?

Maximum thickness depends on material and die size. For accurate limits consult the product datasheet or contact the supplier — using the tool beyond its rated thickness can damage the punch and compromise safety.

6. How do I change punches and dies?

Ensure the system is depressurized, remove the retaining fasteners, replace the punch and die with the matched set, reassemble and torque to the manufacturer's specifications. Always follow the included manual for detailed steps.

7. Is training required to operate the tool?

Basic training in hydraulic tool safety and proper punching technique is recommended. Read the manual, wear appropriate PPE (gloves, eye protection), and practice on scrap material before production use.

8. How do I maintain the CH-60L and pump?

Regularly clean the tool, keep punches and dies sharp, check hydraulic fluid level and quality, inspect hoses and fittings for leaks, and lubricate moving parts as directed in the manual. Replace worn components promptly.

9. What safety precautions should I take?

Always depressurize the system before servicing, wear PPE, keep hands clear of the die area during operation, secure workpieces, and never exceed the rated capacity. Follow all safety instructions in the user manual.

10. Can I use other brands' punches and dies with this unit?

Possibly — compatibility depends on punch shank size and die mounting type. Use only punches/dies that match the CH-60L's specifications. When in doubt, use manufacturer-approved or seller-recommended sets.

11. What are common applications for the CH-60L?

Typical uses include electrical panel fabrication, HVAC ductwork, metal closets, junction boxes, structural and maintenance work where clean, burr-free holes in sheet material are required.

12. How do I bleed air from the hydraulic system?

Follow the pump's bleed procedure in the manual: typically, cycle the pump with the bleed valve open until fluid without air bubbles appears, then close the valve and re-test. Always perform this with the tool secured and depressurized before maintenance.

13. What should I do if the punch jams or fails to cut cleanly?

Stop operation immediately, depressurize the system, inspect punch and die for damage or dullness, check workpiece alignment, and ensure the correct die for material/thickness is used. Replace or sharpen parts as needed.

14. Are spare parts and service available?

Spare punches, dies, seals, and hoses are typically available through the manufacturer or authorized dealers. Contact your supplier for part numbers, service options, and recommended maintenance intervals.

15. Is there a warranty or return policy?

Warranty and return policies vary by seller. Check the product listing or contact the seller/manufacturer for specific warranty coverage, duration, and the process for returns or warranty claims.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading