B21, China Town Mall, Midrand

Centrifugal Fire Pump Set - Including Control System SLD

- Section : Machinery

- Category : Pumps & Parts

- SKU : 1600860029535

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a centrifugal fire pump set?

A centrifugal fire pump set is a type of pump designed to move water or other liquids at high flow rates, specifically for fire protection systems. It uses centrifugal force to increase the pressure of water, making it suitable for firefighting applications.

2. What does the control system SLD do?

The control system SLD (Single Line Diagram) is responsible for monitoring and controlling the operation of the centrifugal fire pump set, ensuring it functions correctly during emergencies. It provides essential information about the pump's status and performance.

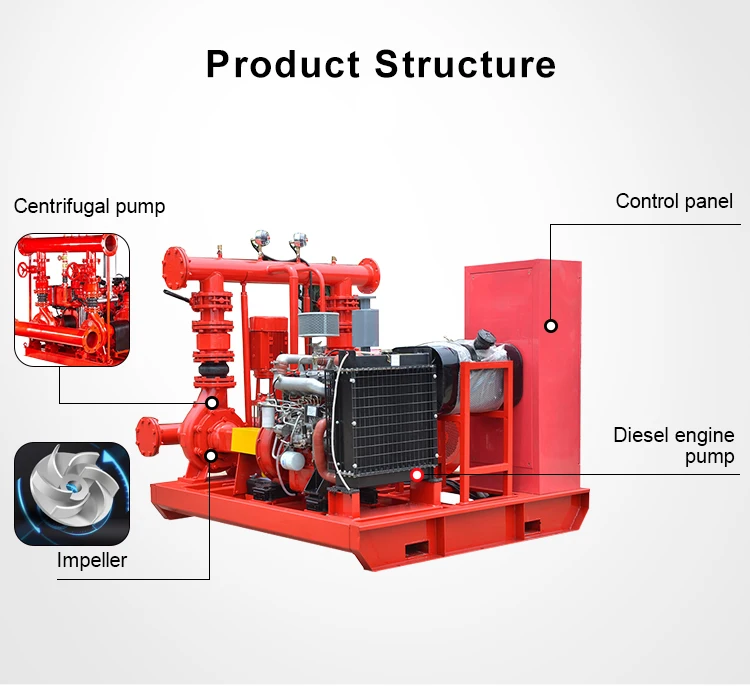

3. What are the main components of the centrifugal fire pump set?

The main components include the pump itself, a motor, a control panel, suction and discharge piping, and various fittings. The control system is also a critical component for managing operations.

4. Is the centrifugal fire pump set suitable for all types of fire protection systems?

Yes, centrifugal fire pump sets are commonly used in various fire protection systems, including sprinkler systems, standpipes, and hydrant systems, making them versatile for different applications.

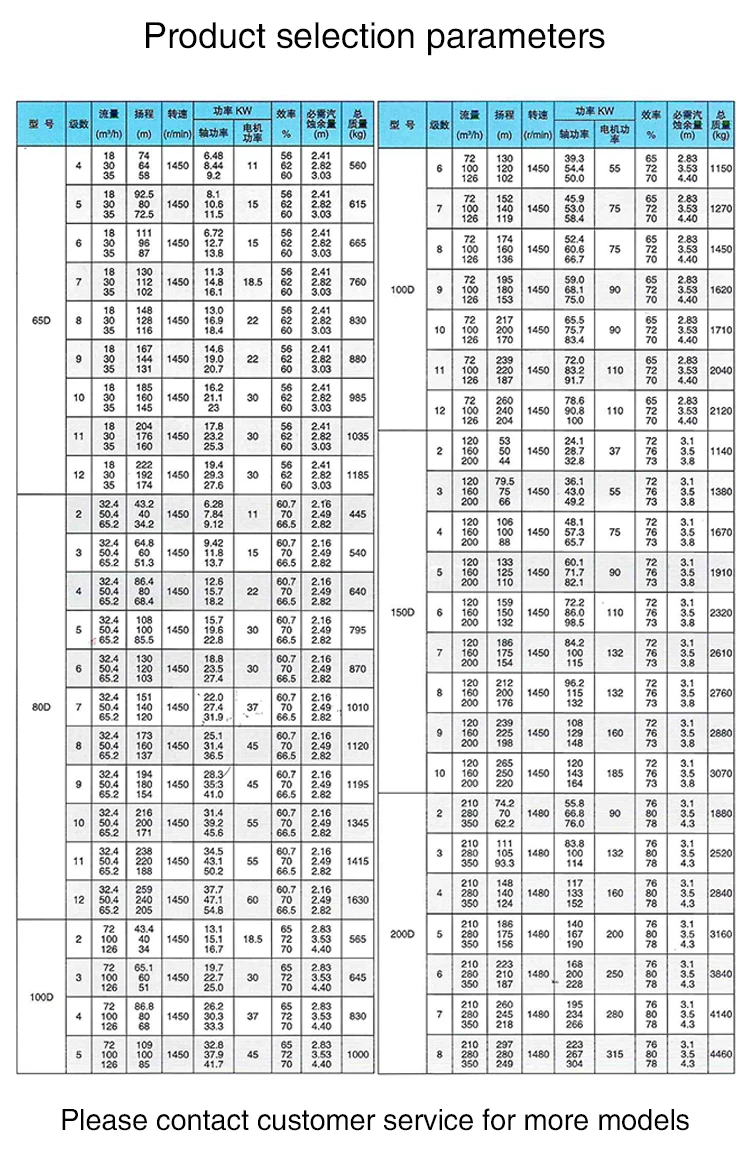

5. What is the typical flow rate of a centrifugal fire pump set?

The flow rate can vary significantly based on the pump's design and application, but centrifugal fire pumps typically range from 250 to 5000 gallons per minute (GPM) or more.

6. How do I maintain the centrifugal fire pump set?

Regular maintenance includes checking fluid levels, inspecting for leaks, testing the control system, and ensuring the pump is free of debris. It is recommended to follow the manufacturer's maintenance guidelines.

7. Can the centrifugal fire pump set operate in extreme weather conditions?

Yes, many centrifugal fire pump sets are designed to operate in a range of temperatures and environmental conditions. However, specific models may require additional features for extreme weather.

8. What power source does the centrifugal fire pump set require?

Centrifugal fire pump sets typically require an electric power source, but some models may also have diesel engines or other alternatives to ensure reliability during power outages.

9. How is the centrifugal fire pump set installed?

Installation should be carried out by qualified professionals. It involves connecting the pump to the water supply, electrical connections for the motor and control system, and ensuring all piping is properly secured.

10. What safety features are included in the centrifugal fire pump set?

Common safety features include pressure relief valves, automatic shut-off mechanisms, and alarms that alert operators to issues like low water levels or pump failures.

11. What certifications should I look for in a centrifugal fire pump set?

Look for certifications from recognized organizations such as Underwriters Laboratories (UL) or Factory Mutual (FM), which ensure the pump meets specific safety and performance standards.

12. How can I determine the right size of centrifugal fire pump set for my needs?

Sizing depends on various factors including the required flow rate, pressure needs, and the layout of the fire protection system. Consulting with a fire protection engineer is recommended for accurate sizing.

13. What warranty is provided with the centrifugal fire pump set?

Warranties vary by manufacturer but typically cover defects in materials and workmanship for a specified period. It's important to check the warranty details before purchase.

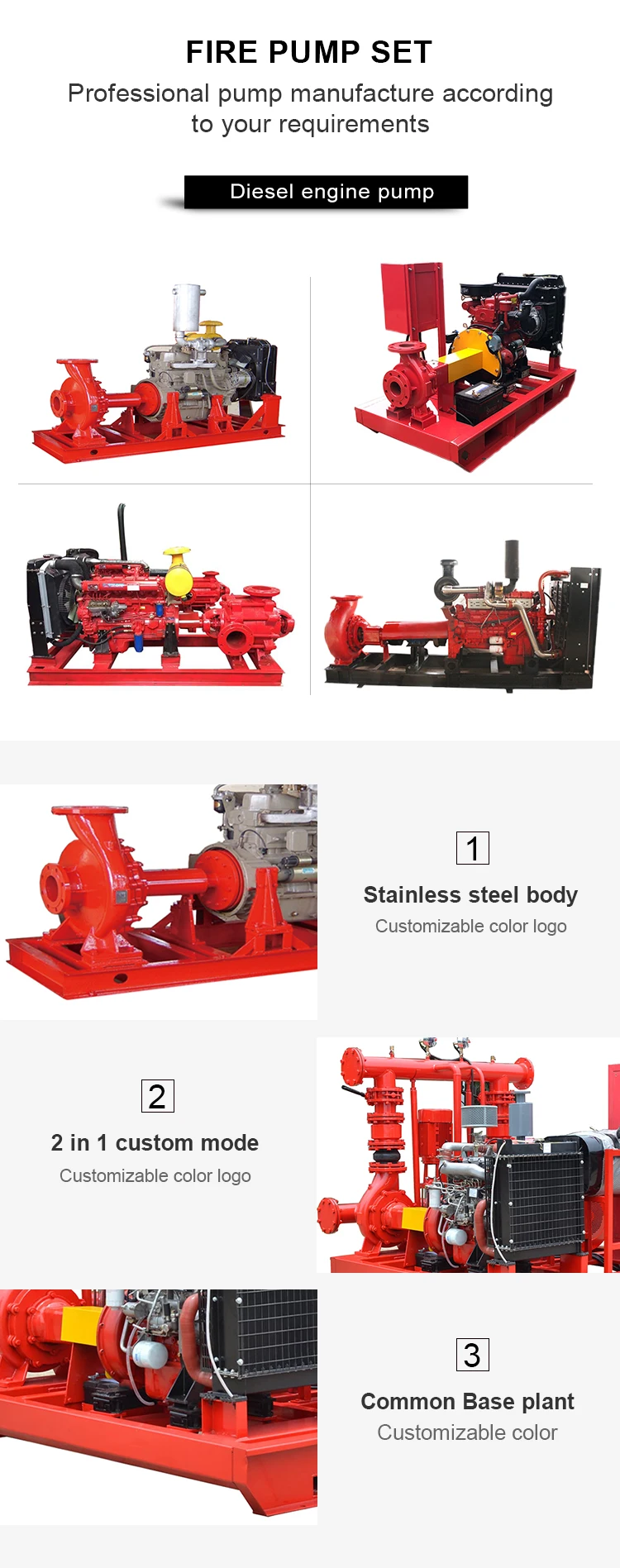

14. Can I customize the centrifugal fire pump set?

Yes, many manufacturers offer customization options for centrifugal fire pump sets to meet specific needs, including modifications in size, flow rate, and control systems.

15. Where can I purchase a centrifugal fire pump set?

Centrifugal fire pump sets can be purchased from specialized industrial equipment suppliers, fire safety equipment retailers, or directly from manufacturers.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading