B21, China Town Mall, Midrand

BT-5600 automotive frame machines tools and equipment

- Section : Sports & Entertainment

- Category : Vehicle Parts & Accessories

- SKU : 60659176347

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

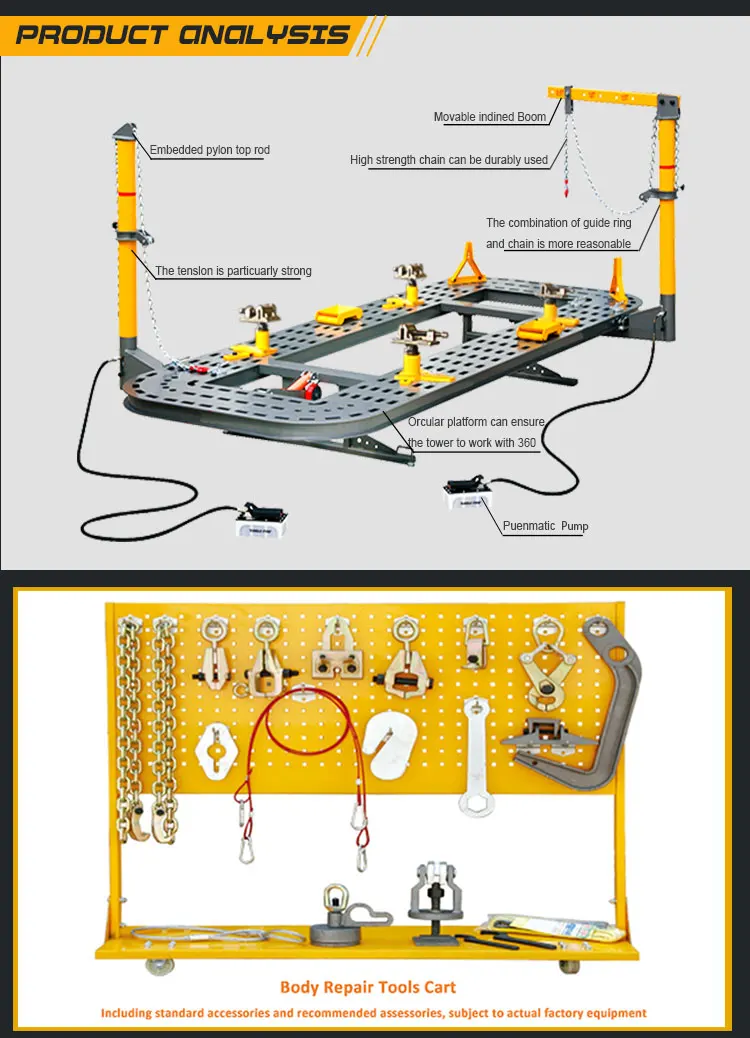

1. What is the BT-5600 automotive frame machine?

The BT-5600 is a hydraulic car frame machine and platform system designed for collision repair, vehicle pulling and alignment. It features a tilted hydraulic lifting platform, a 360° rotating pulling tower and a range of accessory clamps and tools for frame straightening.

2. What are the platform dimensions and lifting capacity?

Platform length 5600 mm (approx. 18'), width 2200 mm (approx. 7.2'), platform height 580 mm (approx. 23"). Maximum loading capacity is 3.5 tonnes.

3. What is the pulling tower capacity and range of motion?

The pulling tower has a rated tower power of 10 tonnes and a full 360° rotation across the platform for flexible pulling directions.

4. How does the lifting system work?

The unit uses a hydraulic tilted lifting platform with a portable flexible lifting leg. The design lifts the vehicle without contact between the platform and the shop floor during lift, reducing potential floor damage.

5. What is the construction quality of the platform and clamps?

The platform is a square-hole type formed by large-scale numerical-control flame cutting for high flatness and strength, with no fixation dead zones. Main clamps are forged; the universal single-jaw clamps are carburized and heat-treated for durability and quick clamping.

6. Are accessory clamps and tools included and are they compatible?

The BT-5600 is designed to work with accessory clamps and tools for a variety of repair and alignment tasks. Specific included items vary by supplier—confirm the package list with your dealer for exact contents.

7. What types and sizes of vehicles can be serviced on this machine?

The machine is intended for collision-damaged vehicles within the platform footprint and up to the 3.5-ton loading capacity. Always verify vehicle dimensions and weight before use.

8. What are the site and installation requirements?

A level, stable workshop floor and enough clear space around the machine for full tower rotation are required. Professional installation and alignment are recommended—contact your supplier for site-prep specifications and anchoring guidance.

9. What are the electrical and hydraulic requirements?

The BT-5600 uses a hydraulic power system. Exact hydraulic pump and electrical supply specifications (voltage, phase, motor power) vary by configuration—refer to the manufacturer’s technical manual or consult your dealer for the correct power unit and hookup requirements.

10. What routine maintenance does the BT-5600 require?

Regular maintenance includes checking hydraulic fluid levels and condition, inspecting hoses and seals for leaks, lubricating moving parts and rollers, checking clamp condition and tightness, and replacing worn components. Follow the manufacturer’s maintenance schedule and procedures.

11. What safety precautions should operators follow?

Do not exceed the 3.5 t capacity, ensure the vehicle is properly positioned and securely clamped before pulling or lifting, keep personnel clear of moving parts and load paths, use trained operators, and follow lockout/tagout and manufacturer safety instructions.

12. How does the pulling tower fixation work?

The pulling tower uses a unique fixation design and a rolling mechanism that provides stable, flexible 360° rotation without dead zones, allowing reliable positioning and secure fixation during pulling operations.

13. Are spare parts and service available?

Spare parts such as clamps, hydraulic components and rollers are typically available through the manufacturer or authorized dealers. Contact your supplier for availability, part numbers and service options.

14. Is operator training available for the BT-5600?

Most dealers and manufacturers provide installation support and operator training or can arrange on-site training. Ask your supplier about training packages, manuals and safety instruction.

15. What are the typical applications for this machine?

Common applications include frame straightening, collision repair, vehicle pulling and alignment tasks for passenger cars and light commercial vehicles within the machine's capacity and footprint.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading