B21, China Town Mall, Midrand

Automatic Woundplast Band-Aid Packing Cartoning Machine

- Section : Machinery

- Category : Packaging Line

- SKU : 1600963655629

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

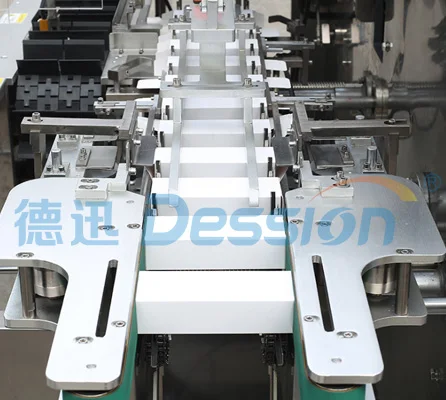

1. What types of products can the Automatic Woundplast Band-Aid Packing Cartoning Machine package?

The machine is designed to package various box-type products including band-aids, medical kits, tea bags, sugar sachets, face masks, and small electronics.

2. What is the maximum capacity of the machine?

The Automatic Woundplast Band-Aid Packing Cartoning Machine has a capacity of 40 to 70 boxes per minute.

3. What are the dimensions of the cartons that can be used with this machine?

The machine can accommodate cartons with sizes ranging from 110-230mm in length, 80-150mm in width, and 30-80mm in height.

4. Is the machine suitable for food packaging?

Yes, the machine is suitable for food packaging as well, including items like tea bags and chocolates.

5. What kind of power supply does the machine require?

The machine requires a power supply of 220V and operates at 50Hz.

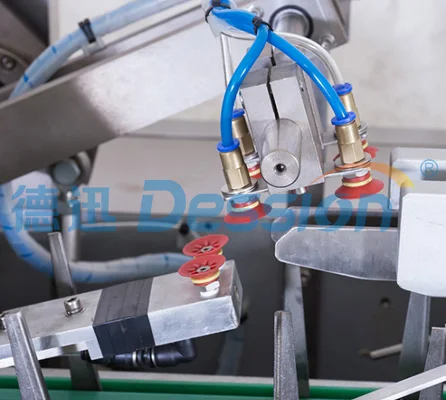

6. How does the quick mold change feature work?

The quick mold change feature allows for easy switching of molds without the need to dismantle the drive chain or hopper, which significantly reduces downtime.

7. What materials is the machine built from?

The machine is constructed with high-quality 304 stainless steel and features imported components like Omron temperature controllers and NSK bearings.

8. Does the machine include safety features?

Yes, the machine includes a dual safeguard system to prevent damage and a one-way handwheel for worker protection.

9. What optional devices can be added to the machine?

Optional devices include a date coding printer, air-filling device, and punching device.

10. What is the weight of the machine?

The weight of the Automatic Woundplast Band-Aid Packing Cartoning Machine is 1300 kg.

11. What is the working process of the machine?

The working process includes product conveyance, carton storage, bag taking, pushing, folding, and sealing, followed by the outlet for finished products.

12. How does the dual cutting knife system benefit the packaging process?

The dual cutting knife system increases the lifespan of the blades compared to traditional single-knife setups, leading to reduced maintenance costs.

13. Can the machine handle different sizes of cartons?

Yes, the machine can handle cartons of various sizes within the specified dimensions of 110-230mm (L) × 80-150mm (W) × 30-80mm (H).

14. Is the machine CE approved?

Yes, the Automatic Woundplast Band-Aid Packing Cartoning Machine is CE approved, ensuring compliance with safety and performance standards.

15. How do I maintain the machine for optimal performance?

Regular maintenance involves checking the electrical and pneumatic systems, keeping the machine clean, and replacing worn components as needed to ensure smooth operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading