B21, China Town Mall, Midrand

Automatic small tea bag tea leaves making packing machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600254899777

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 14 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the machine designed to do?

This is a fully automatic small tea bag and loose tea packing machine that makes bags, meters/fills, seals, codes and cuts in one cycle for small tea bags (three-side or back sealing).

2. What are the main technical specifications (weight range, bag size, film width)?

Weight range: 1–100 g (±0.2 g). Bag length: 20–160 mm. Film width: 50–200 mm. Sealing types: three-side sealing or back sealing.

3. What are the machine dimensions, weight and power requirements?

Machine dimensions: 420×500×1450 mm. Machine weight: 90 kg. Power supply: 220 V or 110 V (custom plug available). Power consumption: 350 W.

4. Which film and bag materials can it handle?

It works with plastic films, laminated films, aluminum foil, filter paper, non-woven fabrics and other heat-sealable compound materials, including filter-paper tea bag materials.

5. How accurate is the dosing?

Standard dosing accuracy is ±0.2 g within the 1–100 g weighing range, enabled by servo control and high-precision metering.

6. What automation and control features does the machine have?

It uses PLC control with a color touch screen, servo drives for precise positioning and dual-axis high-precision output, plus separate pneumatic and electrical control to reduce noise and improve stability.

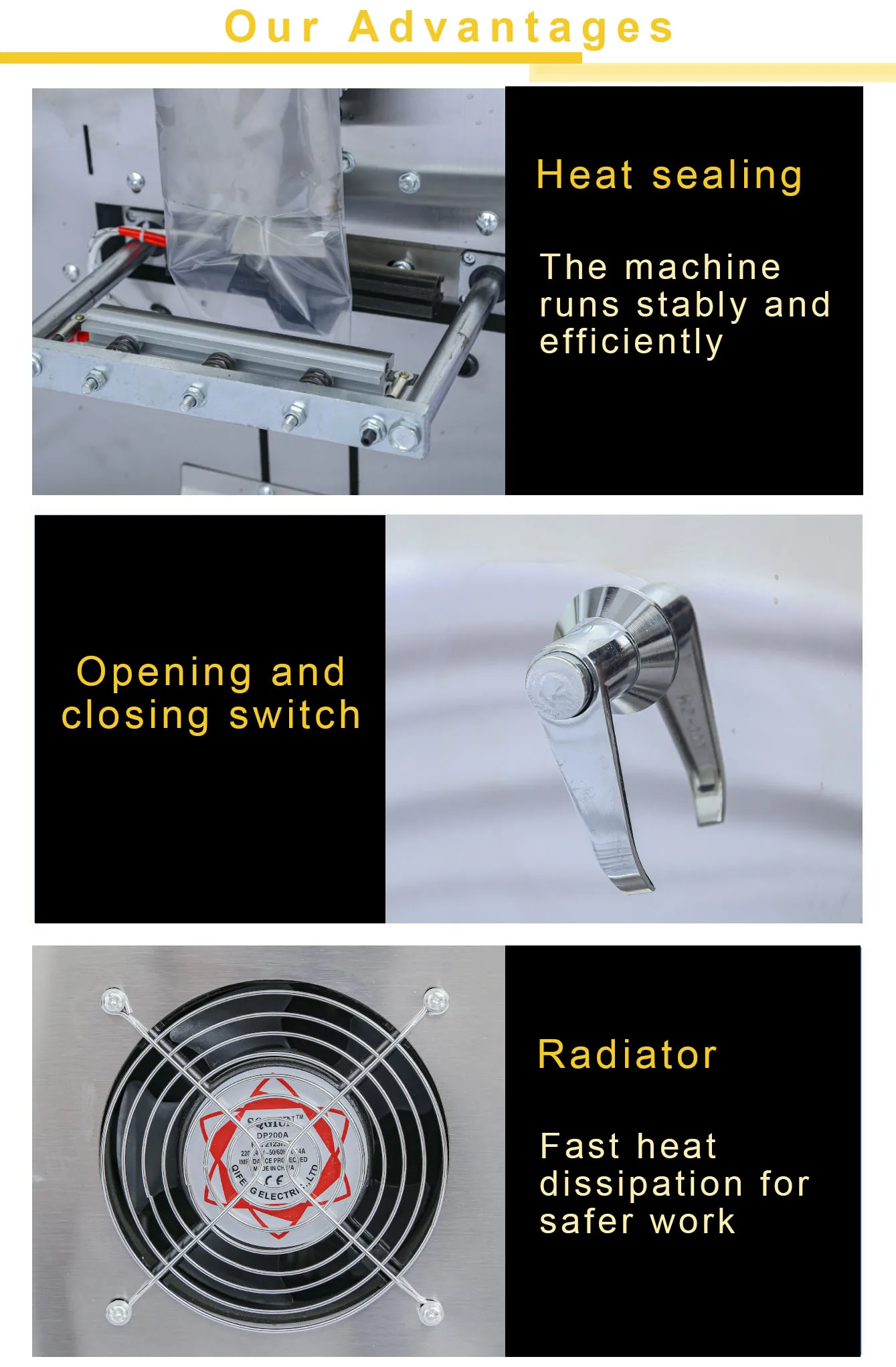

7. What makes this machine different from other suppliers' machines?

Key advantages include a double film hanging frame for stable film feed, extra vibration on the bag former to prevent jamming, Teflon-coated sealing aluminum blocks to avoid sticking, custom voltage/plug, pre-shipment testing with similar products, English-speaking after-sales support, and spare parts included.

8. Is the machine easy to operate and adjust?

Yes. The touch screen lets you set filling weight directly and make bag deviation adjustments without mechanical changes. The updated panel is designed for simple operation.

9. How is hygiene and build quality handled?

The machine is full stainless steel (food grade) with a closed mechanism to prevent dust ingress, suitable for food/tea production and easy to clean.

10. Does the machine require any special installation or local adaptation?

We supply the machine with your country's plug and can set the correct voltage (110 V or 220 V). Basic installation and commissioning are recommended; we offer international after-sales support to assist remotely.

11. Will the machine be tested before shipment?

Yes. We test the machine using a similar product and settings before shipment to ensure it runs correctly for your product, weight and bag size.

12. What spare parts and after-sales service are provided?

We send replacement parts for future use and offer professional international after-sales service in English with fast response times. Specific spare part lists and lead times will be provided on request.

13. How noisy is the machine and what about energy consumption?

The machine separates pneumatic and electrical boxes and uses efficient servo drives for relatively low noise. Power consumption is 350 W.

14. How many boxes and what are the packing dimensions for shipping?

The machine is shipped in two cases. Example packing dimensions are 490×470×470 mm and 560×650×1120 mm, but the final packing sizes may vary slightly depending on accessories.

15. What maintenance and cleaning are required?

Routine maintenance includes cleaning contact surfaces, checking and replacing worn belts or sealing Teflon as needed, inspecting vibrators and film paths, and regular lubrication per the manual. We provide a maintenance guide and can advise on spare parts frequency based on usage.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading